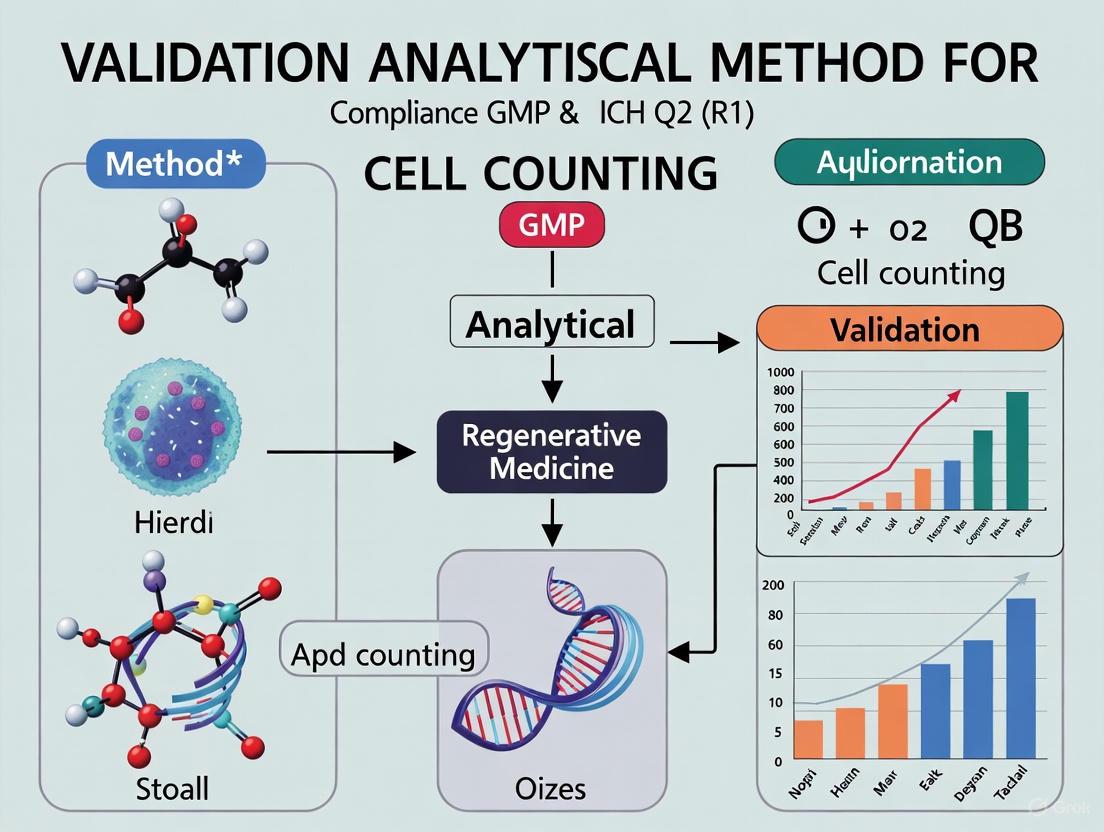

A Practical Guide to Validating Cell Counting Methods for GMP Compliance Under ICH Q2(R1)

This article provides a comprehensive roadmap for researchers, scientists, and drug development professionals tasked with validating cell counting methods in a Good Manufacturing Practice (GMP) environment.

A Practical Guide to Validating Cell Counting Methods for GMP Compliance Under ICH Q2(R1)

Abstract

This article provides a comprehensive roadmap for researchers, scientists, and drug development professionals tasked with validating cell counting methods in a Good Manufacturing Practice (GMP) environment. Aligned with ICH Q2(R1) guidelines, the content spans from foundational regulatory principles and method selection to detailed validation protocols for parameters like accuracy, precision, and linearity. It further addresses common troubleshooting scenarios and offers a comparative analysis of manual versus automated counting technologies, delivering a complete framework to ensure the quality, safety, and efficacy of cell-based therapies.

GMP and ICH Q2(R1) Fundamentals: Building a Compliant Foundation for Cell Counting

This guide provides a comparative analysis of cell counting methods within the context of Good Manufacturing Practice (GMP) for Advanced Therapy Medicinal Products (ATMPs), framing the evaluation within the rigorous requirements of analytical method validation as per ICH Q2(R1).

The Evolving GMP Landscape for ATMPs

The regulatory framework for ATMPs is dynamic, with significant recent developments aimed at ensuring product quality and patient safety. The European Medicines Agency (EMA) has proposed revisions to Part IV of its GMP guidelines specific to ATMPs, focusing on alignment with the revised Annex 1 for sterile medicinal products, integration of ICH Q9 (Quality Risk Management) and ICH Q10 (Pharmaceutical Quality System) principles, and adaptation to new technologies like automated systems and single-use systems [1]. Furthermore, a new EMA Guideline on clinical-stage ATMPs came into effect in July 2025, serving as a primary multidisciplinary reference for clinical trial applications [2]. The International Society for Stem Cell Research (ISSCR) has endorsed these updates, recommending their integration into the main body of EudraLex Volume 4 for more consistent guidance [3]. Simultaneously, new guidance has been issued for managing raw materials, which pose unique challenges as they often come from non-traditional sources (animal, human) and may not be covered by pharmacopeias [4].

Cell Counting: A Critical yet Challenging Analytical Method in ATMP GMP

Cell counting is a foundational analytical procedure in ATMP development and manufacturing. Accurate counts are essential for process control (e.g., monitoring growth, transfection), determining seeding densities, and calculating final product dosage [5] [6]. However, achieving accurate and reliable cell counting is notoriously challenging. A 2020 survey revealed that only 18% of respondents from key industries had high confidence in their cell viability assay results [5]. The complexity stems from several factors:

- Cell Heterogeneity: ATMPs consist of diverse cell types (e.g., MSCs, T cells, hiPSCs) with varying sizes, shapes, and tendencies to clump or aggregate [5].

- Viability Assessment: Distinguishing live from dead cells is user-defined and can be based on membrane integrity, metabolic activity, or proliferative capacity, leading to a spectrum of results [5].

- Process-Related Impurities: The presence of cellular debris, magnetic beads used in cell selection, or components of the suspension medium (e.g., DMSO) can significantly interfere with counting accuracy [5] [6].

Within a GMP environment, any analytical method, including cell counting, must be formally validated to ensure it is fit for its intended purpose. The core principles of ICH Q2(R1) validation include demonstrating accuracy, precision (repeatability, intermediate precision), specificity, range, linearity, and robustness.

Comparative Analysis of Cell Counting Methods

The following table summarizes the key cell counting methods, their operating principles, and their performance characteristics in the context of ATMP manufacturing and ICH Q2(R1) validation.

Table 1: Comparison of Cell Counting Methods for ATMP Applications

| Cell Counting Method | Description | Advantages | Disadvantages & GMP Validation Considerations |

|---|---|---|---|

| Hemocytometer (Manual) [5] [7] | Manual counting using a specialized chamber (e.g., Bürker) under a microscope. | Low cost; suitable for various cell types; direct visualization [5]. | Time-consuming; highly susceptible to human error, leading to poor precision; operator-dependent, challenging to validate for intermediate precision [5] [7]. |

| Automated Image Analysis [5] [7] | Uses optical, electronic, and image processing to count and classify cells (e.g., NucleoCounter NC-100). | Fast speed; high throughput; high precision; automated, reducing operator bias [5] [7]. | Relatively high cost; can be influenced by sample type and condition (e.g., clumps, beads); requires validation of software algorithm [5] [6]. |

| Impedance Cell Counter [5] | Detects changes in electrical resistance as cells pass through an electric field. | Fast speed; high throughput; high precision; automated [5]. | Relatively high cost; inability to differentiate between live and dead cells, failing specificity for viability [5]. |

| Flow Cytometer [5] | Uses optical and electronic tech. to measure multiple parameters of individual cells labeled with fluorescent markers. | High throughput; multi-parameter analysis (size, fluorescence); high sensitivity and accuracy; uses internal calibration microspheres for accuracy [5]. | High cost; requires complex operation and technical experience; stringent requirements for instrument qualification and validation [5]. |

Supporting Experimental Data: Automated vs. Manual Counting Validation

A key study directly compared an automated fluorescence imaging-based method (NucleoCounter NC-100) against the manual hemocytometer for counting human induced pluripotent stem cells (hiPSCs) in a cGMP environment [7]. The validation, performed in accordance with ICH Q2(R1) principles, demonstrated that the automated method showed superior precision (reproducibility) and was validated for accuracy, specificity, range, and linearity [7]. This study provides concrete experimental evidence that automation can effectively replace traditional manual methods, paving the way for more reliable and standardized cell counting in GMP facilities [7].

Experimental Protocol for Cell Counting Method Evaluation

For a method to be suitable for GMP use, its performance must be rigorously evaluated. The International Organization for Standardization (ISO) provides robust guidance in ISO 20391-2:2019, which outlines an experimental design and statistical analysis to quantify counting method performance [6].

The workflow below illustrates the key stages of this experimental design.

Diagram 1: Method Evaluation Workflow

Detailed Methodology [6]:

- Define Sample Types: The evaluation should use cells representative of the entire manufacturing process. This includes samples from different stages, such as:

- Peripheral Blood Mononuclear Cells (PBMCs) after Ficoll separation.

- T cells isolated via positive selection (with magnetic beads attached) and negative selection (without beads).

- Prepare Dilution Series: Create a series of dilutions (e.g., 1:1, 1:2, 1:3, 1:4, 1:5) of the cell sample using an appropriate buffer like Dulbecco's Phosphate Buffered Saline (dPBS) supplemented with Human Serum Albumin (HSA). The concentrations should span the expected operating range of the instrument.

- Assign Random IDs: Each sample tube in the dilution series is assigned a random identification number to prevent operator bias during counting.

- Execute Replicate Counts: For each dilution, multiple sample tubes are prepared (e.g., n=3), and each tube is counted multiple times (e.g., 3 replicates) by the instrument/method being evaluated.

- Statistical Analysis: Data is analyzed according to ISO 20391-2. Key metrics include:

- Proportionality Index: Assesses whether the measured cell concentration is directly proportional to the expected concentration across dilutions. An ideal method has a proportionality index of 1.

- % Coefficient of Variation (%CV): Measures precision. Lower %CV across replicate observations indicates higher repeatability.

The Scientist's Toolkit: Key Reagents and Materials

The table below lists essential materials used in cell counting experiments for ATMP workflows, based on the cited protocols [6].

Table 2: Research Reagent Solutions for Cell Counting in Cell Therapy Workflows

| Item | Function / Application | Example |

|---|---|---|

| Leukopak | Starting material for obtaining human immune cells for therapy manufacturing. | Cryopreserved Leukopak (StemCell Technologies) [6]. |

| Cell Separation Medium | Isolation of peripheral blood mononuclear cells (PBMCs) from whole blood via density gradient centrifugation. | Ficoll-Paque (Cytiva) [6]. |

| Magnetic Beads | Isolation of specific cell types (e.g., T cells) through positive or negative selection. | Dynabeads CD3/CD28 (Positive Selection) / Dynabeads Untouched Human T cells Kit (Negative Selection) [6]. |

| Cell Culture Buffer / Medium | Washing, diluting, and suspending cells during processing; choice of medium can critically impact counting accuracy. | HBSS, CTS Immune Cell SR, Hanks’ Balanced Salt Solution, dPBS with Human Serum Albumin [5] [6]. |

| Fluorescent Stains | Used in many automated systems to distinguish viable and non-viable cells based on membrane integrity. | Acridine Orange (AO) for total cells, Propidium Iodide (PI) for dead cells [5]. |

The choice of cell counting method is a critical decision in ATMP development with direct implications for product quality and regulatory compliance. While traditional manual methods are still used, automated systems, particularly image-based and flow cytometry-based platforms, offer demonstrably superior precision, accuracy, and linearity, making them more amenable to validation under ICH Q2(R1). Successful integration of any counting method into a cGMP workflow requires a systematic, risk-based approach guided by international standards like ISO 20391-2 and a thorough understanding of the evolving regulatory expectations for ATMPs.

The International Council for Harmonisation (ICH) Q2(R1) guideline, titled "Validation of Analytical Procedures: Text and Methodology," provides a comprehensive framework for validating analytical methods used in pharmaceutical development and registration [8]. This guideline harmonizes standards to ensure that analytical procedures consistently produce reliable, accurate results that are acceptable to regulatory authorities globally [9] [8].

Originally established as two separate documents (Q2A in 1994 and Q2B in 1996), these were unified into a single integrated guidance in November 2005 [10] [8] [11]. ICH Q2(R1) serves as a foundational document that defines the key validation parameters required to demonstrate that an analytical procedure is suitable for its intended purpose, particularly for testing drug substances and products, including both chemical and biological/biotechnological products [12] [8].

The primary objective of this guideline is to provide a standardized approach to method validation, ensuring the quality, safety, and efficacy of pharmaceuticals through scientifically sound analytical data [13] [8]. For researchers and drug development professionals, understanding and implementing ICH Q2(R1) is essential for regulatory compliance and successful product registration.

Core Principles and Analytical Procedure Categories

Fundamental Concepts and Definitions

ICH Q2(R1) establishes a standardized vocabulary and methodological approach for analytical validation. An crucial distinction lies between the terms "analytical procedure" and "analytical method". The guideline specifically addresses analytical procedures, which encompass the complete process from sample collection and preparation through to the reporting of results. This is a broader concept than an "analytical method," which typically refers only to the instrumental technique or analytical principle used [11].

The guideline's principles apply to various analytical techniques used in the quality control of pharmaceuticals. While originally developed with a focus on chromatographic methods, its framework is adaptable to other technologies [11]. For any analytical procedure, the fundamental requirement is that it must be validated for its intended use, with the validation extent depending on the application [11].

Categorization of Analytical Procedures

ICH Q2(R1) classifies analytical procedures into three major types based on their purpose in assessing pharmaceutical quality. The table below outlines these categories, their primary objectives, and key validation considerations.

Table 1: Categories of Analytical Procedures as Defined by ICH Q2(R1)

| Category | Primary Objective | Key Question Answered | Critical Validation Parameters |

|---|---|---|---|

| Identification Tests [13] | To verify the identity of an analyte in a sample [13]. | "Does it contain what is declared?" [13] | Specificity (ability to discriminate analyte from similar compounds) [13]. |

| Testing for Impurities [13] | To detect and quantify (or limit) impurities in a sample [13]. | "Does it exclusively contain what is declared?" [13] | Specificity, Accuracy, Precision (for quantitative tests); Detection Limit [13]. |

| Assay Tests [13] | To quantify the major component or measure the potency of a drug substance or product [13]. | "Does it contain as much as declared?" [13] | Specificity, Linearity, Accuracy, Precision [13]. |

This categorization is crucial because it directly influences which validation parameters must be demonstrated and to what extent, ensuring that each analytical procedure is fit for its specific purpose in guaranteeing pharmaceutical quality.

Comprehensive Breakdown of Validation Characteristics

ICH Q2(R1) defines eight key validation characteristics that provide a comprehensive framework for evaluating analytical procedure performance. The following diagram illustrates the workflow for validating an analytical procedure according to this framework, showing the relationships between these core characteristics.

Specificity and Accuracy

Specificity is the ability to assess unequivocally the analyte in the presence of components that may be expected to be present, such as impurities, degradation products, and matrix components [9]. It guarantees your method can accurately discriminate between the target analyte and other components present in the sample matrix [9]. For identification tests, specificity is the most critical parameter, ensuring the procedure can correctly identify the substance in question [13].

Accuracy expresses the closeness of agreement between the value that is accepted as a true value or an accepted reference value and the value found [9]. It measures how closely your test results align with an accepted true value, typically expressed as percent recovery of a known added amount of analyte [9]. For drug substances, accuracy is typically assessed by comparison against a reference standard, while for drug products, spiked placebos or comparison to an established reference method may be used [9].

Precision, Linearity, and Range

Precision measures the degree of agreement among individual test results when the procedure is applied repeatedly to multiple samplings of a homogeneous sample [9]. It is evaluated at three levels:

- Repeatability (intra-assay precision): Expresses the precision under the same operating conditions over a short interval of time [9].

- Intermediate precision: Expresses within-laboratory variations, such as different days, analysts, or equipment [9].

- Reproducibility: Expresses the precision between different laboratories [9].

Precision is typically measured by calculating standard deviation and relative standard deviation (RSD) values, with acceptable precision generally indicated by RSD values below 2% for assay methods and below 15% for impurity determination [9].

Linearity demonstrates the ability of the method to obtain test results that are directly proportional to the concentration of analyte in the sample within a given range [9]. It is typically confirmed through correlation coefficients, with industry consensus generally considering r ≥ 0.995 acceptable for chromatographic methods and r ≥ 0.990 for bioanalytical techniques [9].

Range is the interval between the upper and lower concentrations of analyte in the sample for which it has been demonstrated that the analytical procedure has a suitable level of precision, accuracy, and linearity [9]. For assay methods, ICH Q2(R1) recommends a range of 80-120% of the target concentration [9].

Detection Limit, Quantitation Limit, and Robustness

Detection Limit (DL) is the lowest amount of analyte in a sample that can be detected but not necessarily quantified as an exact value [9]. It represents the lowest analyte concentration that can be reliably detected, though not necessarily quantified [9]. Common approaches for determining DL include signal-to-noise ratio (typically 3:1), standard deviation of the response, and visual evaluation [9].

Quantitation Limit (QL) is the lowest amount of analyte in a sample that can be quantitatively determined with suitable precision and accuracy [9]. While DL confirms the analyte's presence, QL establishes the minimum concentration for reliable quantitative measurement [9]. QL is typically determined using a signal-to-noise ratio of 10:1, standard deviation of response multiplied by a factor (usually 10), or through visual evaluation [9].

Robustness measures the capacity of a method to remain unaffected by small, deliberate variations in method parameters, such as pH, mobile phase composition, temperature, or flow rate in chromatographic methods [9]. It provides an indication of the method's reliability during normal usage and is critical for transfering methods between laboratories [9].

Table 2: Key Validation Characteristics and Their Requirements in ICH Q2(R1)

| Validation Characteristic | Definition | Typical Acceptance Criteria |

|---|---|---|

| Specificity [9] | Ability to measure analyte accurately in the presence of interfering components [9]. | No interference observed [9]. |

| Accuracy [9] | Closeness of test results to the true value [9]. | Recovery of 98-102% for drug substance; 98-102% for drug product [9]. |

| Precision [9] | Degree of agreement among individual test results [9]. | RSD < 2% for assays; RSD < 15% for impurities [9]. |

| Linearity [9] | Ability to obtain results proportional to analyte concentration [9]. | Correlation coefficient (r) ≥ 0.995 (chromatography); r ≥ 0.990 (bioanalytical) [9]. |

| Range [9] | Interval between upper and lower analyte concentrations with suitable precision, accuracy, and linearity [9]. | 80-120% of target concentration (assays); reporting threshold to 120% of specification (impurities) [9]. |

| Detection Limit [9] | Lowest concentration of analyte that can be detected [9]. | Signal-to-noise ratio of 3:1 [9]. |

| Quantitation Limit [9] | Lowest concentration of analyte that can be quantified with acceptable precision and accuracy [9]. | Signal-to-noise ratio of 10:1 [9]. |

| Robustness [9] | Capacity to remain unaffected by small, deliberate variations in method parameters [9]. | System suitability criteria met despite variations [9]. |

Practical Application in Cell Therapy and Bioanalysis

Implementing ICH Q2(R1) in Cell Counting Method Validation

The validation of cell counting methods exemplifies the practical application of ICH Q2(R1) principles in the rapidly advancing field of cell and gene therapies. Accurate cell counting is critical for proper dosage administration in therapies like CAR-T cells, where inaccuracies may lead to inefficacy or unwanted autoimmune responses in patients [14].

However, applying ICH Q2(R1) to cell counting presents unique challenges. According to ISO Cell Counting Standards, accuracy cannot be readily applied in the traditional sense for cell counting methods because there are currently no reference materials for live mammalian cells that are certified for cell concentration [14]. This limitation requires researchers to employ alternative validation approaches.

In practice, the evaluation of cell counting method accuracy needs to be indirectly assessed by orthogonal comparative methods [14]. Furthermore, the ISO Cell Counting Standard Part 2 describes a protocol to simultaneously evaluate precision (repeatability), coefficient of determination (R²), and proportionality as key performance indicators for cell counting methods [14].

Case Study: Validation of T Cell Metabolic Potential Assessment

A practical example of ICH Q2(R1) implementation in cellular therapy appears in the validation of a method evaluating T cell metabolic potential using Seahorse technology. Researchers addressed the method's inter-assay variability by incorporating a JURKAT tumor cell line as an internal quality control material in each experiment [15].

This approach specifically targeted the validation parameters of precision and robustness by using a homogeneous and stable control material to reduce between-plate variation [15]. The validation study followed ICH Q2(R1) guidelines to confirm the method's specificity, accuracy, precision, linearity, and range under defined experimental conditions [15].

This case demonstrates how ICH Q2(R1) principles can be adaptively applied to novel bioanalytical techniques, contributing to improved robustness and potentially supporting Good Manufacturing Practices (GMP)-compliant validation for quality control in T cell-based therapies production [15].

Essential Research Reagent Solutions

The successful implementation of validated analytical procedures requires specific reagent solutions and materials. The following table details key components used in the featured T cell metabolic potential experiment and their functions.

Table 3: Research Reagent Solutions for T Cell Metabolic Potential Assessment

| Reagent/Material | Function/Purpose | Application Context |

|---|---|---|

| JURKAT Cell Line [15] | Homogeneous and stable control material to monitor inter-assay variability [15]. | Internal Quality Control for T cell metabolism studies [15]. |

| XF Cell MitoStress Kit [15] | Contains compounds to evaluate basal, stressed and maximal glycolysis and OXPHOS parameters [15]. | T cell metabolic potential assessment [15]. |

| Oligomycin [15] | ATP synthase inhibitor; added to assess glycolytic capacity [15]. | Seahorse XF MitoStress Test [15]. |

| Carbonyl Cyanide 4-(Trifluoromethoxy)phenylhydrazone (FCCP) [15] | Mitochondrial uncoupler; added to assess maximal respiratory capacity [15]. | Seahorse XF MitoStress Test [15]. |

| Glucose-Containing Medium [15] | Provides energy substrate for cellular metabolism during assessment [15]. | Baseline metabolic measurements [15]. |

Recent Developments: Transition to ICH Q2(R2) and Q14

While ICH Q2(R1) remains the current implemented guideline, the ICH has recently adopted updated versions to address evolving analytical technologies and applications. The revision to ICH Q2(R2) and the introduction of ICH Q14 ("Analytical Procedure Development") represent significant advancements in the standards governing analytical procedure development and validation [16].

Key enhancements in these updated guidelines include:

- Introduction of a lifecycle approach that advocates for continuous validation and assessment throughout the method's operational use, rather than treating validation as a one-time event [16].

- Enhanced method development practices that incorporate Quality by Design (QbD) principles, focusing on defining the Analytical Target Profile (ATP) early in the process [16] [11].

- Refinements to validation parameters including more comprehensive requirements for accuracy and precision, and mandatory robustness testing tied to the lifecycle approach [16].

These updates are particularly relevant for biologics and complex analytical techniques, as the original ICH Q2(R1) was primarily designed around the needs of traditional small molecule drugs and lacked specific guidance for the unique challenges posed by biologics [16].

The ICH Q2(R1) framework provides an essential foundation for ensuring the reliability and consistency of analytical procedures in pharmaceutical development and quality control. By defining clear validation characteristics and requirements, this guideline enables researchers and drug development professionals to demonstrate that their analytical methods are scientifically sound and fit for their intended purposes.

As the pharmaceutical landscape evolves with increasingly complex biologics and cell-based therapies, the principles of ICH Q2(R1) remain relevant, even as the framework itself advances with the recent adoption of ICH Q2(R2) and Q14. Understanding these core principles is crucial for developing robust, validated analytical procedures that meet regulatory expectations and ensure product quality, safety, and efficacy.

Publish Comparison Guides

In the development and manufacturing of cell and gene therapies, accurate cell counting is a foundational analytical procedure that directly impacts product identity, purity, potency, and safety [17]. For advanced therapy medicinal products (ATMPs), cell counting is not merely a preliminary step; it is a potency assay, determining the therapeutic dose delivered to a patient [18]. A subpotent batch can lead to lack of efficacy, while an overpotent one may cause adverse reactions [19]. Consequently, validating the cell counting method according to rigorous standards is not optional—it is a regulatory imperative.

This guide provides a structured framework for selecting and validating cell counting methods under the International Council for Harmonisation (ICH) Q2(R1) guideline and good manufacturing practice (GMP) principles [18] [19]. We objectively compare manual and automated counting technologies, supported by experimental data, and outline the experimental protocols required to generate validation evidence.

The Regulatory Framework: ICH Q2(R1) and GMP

The ICH Q2(R1) guideline, "Validation of Analytical Procedures," defines the core validation parameters required to demonstrate that an analytical method is suitable for its intended purpose [18]. For a cell counting method used in GMP manufacturing, this typically involves assessing the following parameters [18] [19]:

- Accuracy: Expresses the closeness of agreement between the test result and an accepted reference value.

- Precision: This includes repeatability (intra-assay precision) and intermediate precision (inter-operator, inter-instrument reproducibility).

- Linearity & Range: The ability to obtain results directly proportional to the analyte (cell) concentration within a given range.

- Specificity: The ability to assess the analyte unequivocally in the presence of other components like debris or magnetic beads.

A significant challenge in cell counting is the general lack of universally available reference materials for live mammalian cells, making direct accuracy assessment difficult [14] [20]. To address this, standards organizations have developed alternative approaches. The ISO 20391-2 standard provides an experimental design based on a dilution series, which uses the principle of proportionality as an internal control to quantify method performance in the absence of a reference material [14] [21] [20].

The following diagram illustrates the logical relationship between the regulatory framework, the analytical challenge, and the standardized solution for method evaluation.

Comparison of Cell Counting Methods and Performance Data

Cell counting methods fall into two broad categories: manual hemocytometers and automated systems. Automated systems can be further divided into image-based cytometers and flow-based systems.

Performance Comparison Table

The table below summarizes key characteristics and performance data from published studies comparing these methods.

| Method Category | Specific Method/Instrument | Precision (Average %CV) | Linearity (R²) | Key Advantages | Key Limitations |

|---|---|---|---|---|---|

| Manual | Bürker Hemocytometer [18] [19] | 10.0% - 14.5% [22] | 0.993 - 0.998 [22] | Pharmacopeia reference; low equipment cost [18]. | Low throughput; high operator dependency & variability [19] [22]. |

| Manual | Neubauer Improved Hemocytometer [23] | ~13.4% [22] | Information missing | Widely used; reasonable technical performance [23]. | Subjective; time-consuming; moderate precision [23]. |

| Automated Image-Based | NucleoCounter NC-100 [19] | Higher than manual [19] | Information missing | High precision; fast; cGMP validated for hiPSCs [19]. | Higher instrument cost; requires specific consumables. |

| Automated Image-Based | CellDrop System (Avg. of 3 instruments) [22] | 4.7% - 6.9% [22] | 0.996 - 0.999 [22] | High precision & linearity; time savings (<10 sec/sample) [22]. | Information missing |

| Automated Flow-Based | Flow Cytometry (SSC or fluorescence) [23] | Deficient accuracy and precision [23] | Information missing | High reproducibility; agreement between flow methods [23]. | Deficient accuracy/precision for microspores; high cost [23]. |

Contextualizing the Data

The data in the table reveals clear trends. Automated image-based counters, such as the CellDrop and NucleoCounter, consistently demonstrate superior precision (lower %CV) and excellent linearity (R² > 0.99) compared to manual methods [19] [22]. One study noted that flow cytometry, while excellent for cell population analysis, showed deficient accuracy and precision for counting plant microspores, highlighting that the "best" method is context-dependent and must be validated for the specific cell type [23].

Experimental Protocols for Method Evaluation and Validation

To generate the comparative data presented, researchers employ standardized experimental designs. Two primary protocols are used: one for general method performance evaluation and another for formal validation per ICH Q2(R1).

Evaluating Performance with ISO 20391-2 Dilution Series

This protocol is ideal for selecting or qualifying a method before full GMP validation. It assesses precision and proportionality without a reference material [14] [21] [20].

- Objective: To evaluate the quality of a cell counting method by calculating precision (%CV) and a proportionality index (PI).

- Cell Sample: A homogeneous stock solution of the cell type of interest (e.g., T cells, hiPSCs).

- Experimental Design:

- Create a dilution series from the stock (e.g., 1:1, 1:2, 1:3, 1:4, 1:5) using independent dilution steps [21].

- Verify dilution integrity by weighing pipetted volumes to confirm accuracy [23].

- For each dilution level, prepare multiple replicate sample tubes (e.g., n=3).

- Assign random IDs to tubes to eliminate counting bias.

- Count each replicate multiple times (e.g., k=3) using the method under evaluation.

- Statistical Analysis:

- Precision: Calculate the % Coefficient of Variation (%CV) for the replicate measurements at each dilution level. Lower %CV indicates higher repeatability [20].

- Proportionality: Plot the measured cell concentration against the dilution factor. A high coefficient of determination (R²) and a Proportionality Index (PI) close to 1 indicate that the count is linearly proportional to the dilution, a hallmark of a robust method [14] [20].

The workflow for this experimental design is summarized in the following diagram.

Validation Protocol per ICH Q2(R1) for GMP

For formal method validation, the protocol is expanded to meet specific ICH criteria [18] [19].

- Objective: To validate a cell counting method for accuracy, precision, linearity, and range according to ICH Q2(R1).

- Reference & Test Methods: The pharmacopeial method (e.g., Bürker hemocytometer) is often used as the reference comparator against the new automated method [18] [19].

- Experimental Design:

- Accuracy: Compare results from the test method against the reference method using a statistically significant number of samples from different batches.

- Precision (Repeatability & Intermediate Precision):

- Repeatability: One operator counts the same homogeneous sample multiple times in one session.

- Intermediate Precision: Different operators count the same sample on different days or with different instruments.

- Linearity & Range: Prepare a series of samples across a specified range of concentrations (e.g., from 2.5 x 10⁵ cells/mL to 2.0 x 10⁶ cells/mL). The method's response should be linear across this "range," which is the intended operating concentration [18] [22].

- Specificity: Test the method's ability to distinguish viable cells from dead cells or debris, and to count cells in complex matrices (e.g., with magnetic beads present from cell isolation) [21].

The Scientist's Toolkit: Essential Research Reagent Solutions

The following table details key materials and reagents commonly used in cell counting experiments for therapy development.

| Item | Function / Application | Examples / Notes |

|---|---|---|

| Hemocytometer | Manual cell counting chamber. Reference method in validation. | Bürker (in Eur. Ph.) [18] [19], Neubauer Improved [23]. |

| Automated Cell Counter | Instrument for rapid, reproducible cell counting and viability. | Image-based (NucleoCounter [19], CellDrop [22]); Flow-based (Flow cytometer [21] [23]). |

| Vital Stain | Distinguishes live from dead cells for viability assessment. | Trypan Blue [18] [22]. |

| Fluorescent Stain | Used with fluorescent-capable automated counters for viability. | Propidium Iodide (PI) stains dead cells [23]; Acridine Orange (AO) stains all nuclei. |

| Lysing Solution | Removes red blood cells from samples like leukopaks or blood. | Tuerk's solution [18]; commercial ammonium chloride-based buffers. |

| Magnetic Beads | Isolate target cells (e.g., T cells) from a heterogeneous mixture. | Bead-bound cells (positive selection) pose a challenge for some image algorithms [21]. |

| Buffer with Protein | Diluent for creating cell dilution series; protein prevents adhesion. | dPBS with Human Serum Albumin (HSA) [21]. |

Selecting and validating a cell counting method is a critical, multi-faceted process in cell therapy development. The experimental data clearly shows that automated image-based systems offer significant advantages in precision, speed, and reproducibility over manual hemocytometers, making them strong candidates for GMP workflows [19] [22].

The recommended path forward is a two-stage approach:

- Method Selection & Qualification: Use the ISO 20391-2 dilution series framework to objectively compare the performance of different methods for your specific cell type and process. This provides data-driven evidence for selecting a fit-for-purpose method [14] [20].

- Formal GMP Validation: Once a method is selected, conduct a full ICH Q2(R1) validation for parameters like accuracy (vs. a reference), precision, linearity, and range. This generates the formal evidence required for regulatory submissions and product batch release [18] [19].

By adhering to these structured experimental protocols, researchers and drug developers can ensure the reliability of a fundamental measurement, thereby underpinning the quality, safety, and efficacy of advanced cell and gene therapies.

The Critical Role of Cell Counting as a Potency Test in Cell Therapy Products

In the tightly regulated field of cell therapy, potency testing stands as a critical gatekeeper, serving as definitive evidence that a therapeutic product possesses the specific biological activity required to achieve its intended clinical effect. Among the various analytical methods employed, cell counting emerges as a surprisingly fundamental potency test. Recent analysis of regulatory documents for the 31 U.S. Food and Drug Administration (FDA)-approved cell therapy products (CTPs) reveals that measurements of cell viability and count constitute the most frequently used category of potency tests, employed by 61% (19 of 31) of all approved CTPs [24]. This article explores the critical role of cell counting within the potency testing landscape, objectively comparing the performance of different counting methodologies and framing their validation within the rigorous requirements of current Good Manufacturing Practice (cGMP) and ICH Q2(R1).

The Regulatory Imperative: Cell Counting in Approved Therapies

Prevalence in Approved Products

The justification for treating cell counting as a potency test is strongly supported by regulatory precedent. A comprehensive 2025 review of FDA-approved CTPs found that each product employs an average of 3.4 potency tests, with "Viability and count" representing the single largest category, accounting for 52% (37 of 71) of all non-redacted potency tests [24]. This data underscores that regulatory agencies do not view cell counting as a mere quality check, but as a fundamental measurement of a product's therapeutic capacity.

Potency Testing Framework

Within the regulatory framework, potency is defined as "the specific ability or capacity of the product to affect a given result" [25]. For cell therapies, where the active substance is the cell itself, the quantity of viable cells directly constitutes the product's "strength." Consequently, cell counting serves multiple critical functions:

- Dose Determination: Directly determines the number of viable cells administered to a patient.

- Process Control: Monitors cell expansion and health during manufacturing.

- Product Consistency: Ensures batch-to-batch uniformity in the final product.

- Stability Indicating: Tracks product degradation over time [26] [17].

The table below summarizes the prevalence of different potency test categories for FDA-approved CTPs, demonstrating the dominance of viability and count measurements [24].

Table 1: Categories of Potency Tests Used in 31 FDA-Approved Cell Therapy Products

| Potency Test Category | Number of Tests | Percentage of Non-Redacted Tests | CTPs Using This Category |

|---|---|---|---|

| Viability and Count | 37 | 52% | 19 (61%) |

| Expression | 19 | 27% | 20 (65%) |

| Bioassays | 7 | 7% | 7 (23%) |

| Genetic Modification | 6 | 9% | 6 (19%) |

| Histology | 2 | 3% | 2 (6%) |

Method Comparison: Manual vs. Automated Cell Counting

Performance Attribute Validation

Cell counting methods must be rigorously validated according to ICH Q2(R1) guidelines to ensure their suitability for cGMP environments. The following table synthesizes data from multiple validation studies comparing manual hemocytometry with automated counting systems, highlighting key performance differences [26] [19] [27].

Table 2: Performance Comparison of Cell Counting Methods in cGMP Environments

| Validation Parameter | Manual Hemocytometer | Semi-Automated (Countess) | Fully Automated (Vi-CELL XR) |

|---|---|---|---|

| Accuracy | Reference Method | >95% vs. Hemocytometer | >95% vs. Hemocytometer |

| Precision (CV%) | 5-10% (Viable Cells) | <10% (Total); <5% (Viable) | <5% (Intra-operator) |

| Linearity Range | 2.5×10⁵–8.0×10⁶ cells/mL | 1×10⁴–1×10⁷ cells/mL | 5×10⁴–1×10⁷ cells/mL |

| Sample Volume | 50 μL | 20 μL | 500 μL |

| Analysis Time | Sample Concentration-Dependent | <1 minute | <2.5 minutes |

| Staining Options | Multiple (TB, Erythrosin B, etc.) | Trypan Blue primarily | Trypan Blue primarily |

| Operator Dependency | High | Moderate | Low |

Analytical Workflow and Decision Process

The validation of cell counting methods follows a systematic workflow aligned with cGMP principles, from initial method selection through to routine implementation. The diagram below illustrates this analytical lifecycle and the key decision points for method suitability.

Experimental Protocols for Method Validation

Validation According to ICH Q2(R1)

For a cell counting method to be acceptable in a cGMP environment, it must undergo comprehensive validation. The following protocols are adapted from published validation studies and align with ICH Q2(R1) requirements [26] [27].

Accuracy Assessment Protocol

- Objective: Demonstrate that the alternative method (automated counter) provides results equivalent to the reference method (manual hemocytometer).

- Materials: Cell suspension (e.g., CHO-K1, U937, or hiPSCs), trypan blue solution (0.4%-0.8%), hemocytometer, automated cell counter (e.g., NucleoCounter NC-100, Vi-CELL XR, or Countess).

- Procedure:

- Prepare a homogeneous cell suspension at approximately 1×10⁶ cells/mL.

- For manual counting: Mix 50 μL cell suspension with 50 μL trypan blue. Load 20 μL onto hemocytometer. Count viable (unstained) cells in four corner squares.

- For automated counting: Follow manufacturer's instructions for sample loading and analysis.

- Analyze at least five independent samples by both methods.

- Calculate accuracy as percentage agreement: (Automated count/Manual count) × 100%.

- Acceptance Criterion: Accuracy ≥90% compared to reference method [27].

Precision and Repeatability Testing

- Objective: Determine intra-assay (repeatability) and inter-operator (intermediate precision) variability.

- Materials: Cell suspension at low, medium, and high concentrations within the linear range.

- Procedure:

- Prepare three cell suspensions at 2×10⁵, 1×10⁶, and 5×10⁶ cells/mL.

- For intra-assay precision: A single operator performs ten replicate counts of each concentration in one session.

- For inter-operator precision: Three different operators each perform five replicate counts of the same cell suspensions.

- Calculate coefficient of variation (CV%) for each concentration: (Standard Deviation/Mean) × 100%.

- Acceptance Criterion: CV% <10% for total cells; CV% <5% for viable cells [26].

GMP-Compliant Sample Preparation

Standardized sample preparation is critical for reproducible cell counting results. The workflow below outlines the optimal procedure for viable cell counting using trypan blue exclusion in a GMP environment.

The Scientist's Toolkit: Essential Reagents and Materials

Successful implementation of cell counting as a potency test requires specific, qualified reagents and materials. The following table details essential components and their functions in a GMP-compliant workflow.

Table 3: Essential Research Reagent Solutions for Cell Counting Validation

| Reagent/Material | Function | GMP Considerations | Example Products |

|---|---|---|---|

| Trypan Blue Solution | Viability stain; distinguishes viable/non-viable cells | Concentration standardization (0.4-0.8%); qualification of each lot | Gibco Trypan Blue; Vi-CELL XR Quad Pak Reagent |

| Size Standard Beads | Instrument calibration and verification | Certified reference materials with traceable documentation | Coulter CC Size Standard Mix; ViaCheck Control Beads |

| Viability Controls | Assay performance qualification | Pre-defined viability levels (0%, 50%, 75%, 90%, 100%) | ViaCheck Control Beads (0-100% viability) |

| Counting Chambers | Sample containment for analysis | Disposable preferred to avoid cross-contamination | Bürker chamber; Fast Read 102; Countess chamber slides |

| PBS/Dilution Buffer | Sample dilution to counting range | Sterile, endotoxin-free, qualified for cell culture | Gibco PBS; Phosphate Buffered Saline 1X |

Strategic Implementation in Cell Therapy Development

Phase-Appropriate Validation

The American Society of Gene & Cell Therapy (ASGCT) emphasizes that potency assurance strategies should be phase-appropriate throughout product development [28]. In early-phase trials, cell counting may serve as the primary potency test, with validation evolving as the product advances. This approach is particularly relevant for autologous therapies with limited batch numbers and significant patient-to-patient variability.

Integration with Potency Assay Matrix

For many advanced CTPs, particularly those with complex mechanisms of action like CAR-T cells, cell counting rarely stands alone as the sole potency measure. Instead, it functions as part of a comprehensive potency assay matrix that may include:

- Expression analysis (e.g., CAR expression by flow cytometry)

- Functional bioassays (e.g., cytokine release, cytotoxicity)

- Genomic assays (e.g., vector copy number) [24] [29]

This multi-attribute approach provides orthogonal verification of product quality and biological function, with cell counting serving as the foundational element that ensures proper dosing of viable cellular material.

Cell counting maintains a critical, though sometimes underestimated, role as a potency test for cell therapy products. Its prominence in regulatory submissions for approved products, combined with its direct relationship to product dosing and quality, justifies its position as an essential release parameter. The validation of cell counting methods according to ICH Q2(R1) guidelines ensures that this fundamental measurement provides the accuracy, precision, and reliability required in cGMP manufacturing. As the cell therapy field continues to evolve with increasingly complex products, cell counting will remain the bedrock upon which additional, more specialized potency measures are built, together ensuring that patients receive therapies with consistent quality and predictable biological activity.

In the development and manufacturing of cell and gene therapies, accurate cell counting is a fundamental analytical procedure critical for dosing, potency assessment, and process control. This process is governed by a framework of regulatory requirements and supplementary standards, primarily the ICH Q2(R1) validation guideline, the European Pharmacopoeia (Ph. Eur.), and the ISO 20391 cell counting standards [19] [14]. While ICH Q2(R1) provides the overarching principles for validating analytical procedures, the Ph. Eur. and ISO standards offer specific, practical guidance for implementing these principles in the context of cell counting [19] [5]. The Ph. Eur., as a legally binding document in Europe, provides specific methods and acceptance criteria, with its 10th edition including a manual hemocytometer method as a reference point [19] [7]. In parallel, the ISO 20391 series addresses the unique challenges of counting complex biological entities by providing a standardized framework for evaluating method performance, particularly in the absence of certified reference materials [14] [20]. This guide objectively compares these frameworks and their application in a Current Good Manufacturing Practice (cGMP) environment for cell-based therapies.

Core Standards Comparison and Interrelationship

The following table summarizes the key characteristics, roles, and requirements of the three core documents governing cell counting validation.

Table 1: Comparison of Core Cell Counting Standards and Guidelines

| Feature | ICH Q2(R1) | European Pharmacopoeia (Ph. Eur.) | ISO 20391 (Parts 1 & 2) |

|---|---|---|---|

| Primary Role | Regulatory guideline for validating analytical methods [19] | Legal compendium of official methods and specifications [19] | International standard for evaluating counting method performance [14] [5] |

| Status | Regulatory requirement | Legally binding in member states [19] | Voluntary technical standard |

| Key Focus | General principles for accuracy, precision, specificity, etc. [19] | Providing specific, compendial methods like the hemocytometer [19] | Statistical analysis and experimental design for counting processes [14] [20] |

| Approach to Accuracy | Direct assessment of accuracy required | Implied via use of a compendial reference method [19] | Indirect assessment via proportionality and precision in the absence of reference materials [14] [20] |

The interaction between these documents forms a complete validation strategy. ICH Q2(R1) sets the goals, the Ph. Eur. can provide a validated reference method, and ISO 20391 supplies the tools to evaluate and compare methods against that reference or to qualify a new method when no reference exists [19] [14] [20].

Figure 1: The complementary roles of ICH, Ph. Eur., and ISO standards in achieving a validated cell counting method.

Experimental Validation: An Automated vs. Manual Case Study

A pivotal study demonstrating the practical application of these standards validated an automated fluorescence-based system (NucleoCounter NC-100) against the Ph. Eur. manual hemocytometer method for counting human induced pluripotent stem cells (hiPSCs) manufactured under cGMP [19] [7]. The validation strategy was explicitly designed to comply with EudraLex cGMP regulations and ICH Q2(R1) indications [19].

Detailed Experimental Protocol

The methodology provides a template for a standards-compliant validation [19]:

- Sample Preparation: hiPSCs were expanded under defined cGMP conditions. Cells were dissociated into a single-cell suspension for counting.

- Reference & Test Methods: The manual Bürker hemocytometer (as per Ph. Eur. 10th edition) served as the reference method. The automated NucleoCounter NC-100 was the test method.

- Validation Parameters & Testing:

- Accuracy: Assessed by comparing results from the automated method against the manual reference method across a range of concentrations.

- Specificity: Evaluated the method's ability to distinguish live from dead cells using fluorescent dyes (e.g., acridine orange and propidium iodide).

- Precision:

- Intra-operator reproducibility: Multiple replicates by a single operator.

- Inter-operator reproducibility: Multiple replicates by different operators.

- Range and Linearity: Cells were serially diluted and counted to establish the concentration range over which the method provides accurate and linear results.

Key Experimental Data and Results

The study generated quantitative data demonstrating the comparative performance of the two methods, summarized in the table below.

Table 2: Experimental Performance Data from hiPSC Counting Validation Study [19]

| Performance Parameter | Manual Hemocytometer (Ph. Eur.) | Automated NC-100 System |

|---|---|---|

| Precision (Reproducibility) | Lower (Higher operator-dependent variability) | Higher (Superior intra- and inter-operator reproducibility) |

| Operational Speed | Time-consuming | Significantly faster |

| Dependence on Operator | High | Low (Automated process) |

| Overall Effectiveness for cGMP | Less effective for large-scale manufacturing | More effective, supporting clinical-scale production |

The conclusion was that the automated method showed higher precision and operational efficiency and was successfully validated for use in the cGMP manufacturing of hiPSCs, fulfilling ICH Q2(R1) criteria [19].

Implementing ISO 20391 for Method Evaluation and Comparison

The ISO 20391-2 standard provides a robust, statistical framework for evaluating cell counting method performance, which is particularly valuable when a Ph. Eur. method is unsuitable or when comparing multiple methods for "fitness-for-purpose" [14] [21] [20].

The Dilution Series Experimental Workflow

The core of the ISO 20391-2 approach is a dilution series experimental design that uses the principle of proportionality as an internal control.

Figure 2: ISO 20391-2 experimental workflow for evaluating counting method performance.

Protocol for ISO 20391-2 Compliant Study

- Sample Preparation: A homogeneous stock cell suspension is prepared. The cell type and suspension medium should reflect the intended real-world application [21] [20].

- Independent Dilution Series: A series of dilutions (e.g., 1:1, 1:2, 1:3, 1:4, 1:5) is prepared independently from the stock. Dilution integrity should be verified, for example, by using calibrated scales to measure pipetted volumes [20].

- Replication and Randomization: For each dilution level, multiple sample replicates are prepared (e.g., n=3). All samples are randomized and blinded before counting to prevent operator bias [21].

- Measurement: Each replicate is counted multiple times using the counting method(s) under evaluation.

- Statistical Analysis and Key Metrics:

The Scientist's Toolkit: Essential Reagents and Materials

The following table catalogues key materials required for executing the cell counting validation protocols described in this guide.

Table 3: Essential Research Reagent Solutions for Cell Counting Validation

| Item | Function / Description | Example Use Case |

|---|---|---|

| Bürker Hemocytometer | A glass counting chamber with a calibrated grid for manual microscopy-based cell counting. | Reference method as specified in the European Pharmacopoeia [19]. |

| Fluorescence Imaging-Based Counter | Automated instrument (e.g., NucleoCounter systems) using dyes to identify and count live/dead cells. | Validated test method for high-precision, reproducible counting in cGMP [19]. |

| Viability Stains (e.g., Acridine Orange/Propidium Iodide) | Fluorescent dyes that distinguish live (AO+, PI-) from dead (AO+, PI+) cells based on membrane integrity. | Used in automated systems for specific live/dead quantification [19] [5]. |

| Trypan Blue | A diazo dye excluded by viable cells with intact membranes; used for manual viability assessment. | Standard stain for manual hemocytometer counting [30]. |

| Appropriate Suspension Medium (e.g., PBS with HSA) | A buffer that maintains cell integrity and staining efficacy during the counting process. | Critical for accurate counts; culture medium is often preferred over saline to maintain staining [5] [21]. |

| Magnetic Beads (for Cell Therapy) | Beads used for isolating specific cell types (e.g., T-cells) from heterogeneous mixtures. | Counting in the presence of beads requires method adjustment to avoid skewing results [21]. |

Navigating the supplementary standards for cell counting reveals a cohesive, multi-tiered system. The ICH Q2(R1) guideline provides the foundational validation objectives. The European Pharmacopoeia offers established, legally recognized reference methods against which new technologies can be benchmarked. The ISO 20391 standards deliver the critical statistical tools and experimental designs to rigorously evaluate, compare, and qualify cell counting methods, especially in the absence of a reference material. For researchers and drug development professionals, the synergistic application of these standards, as demonstrated in the cited case studies, provides a robust pathway to ensuring that cell counting methods are not only validated per regulatory doctrine but are also fit-for-purpose in the complex and evolving landscape of cellular therapeutics.

From Theory to Practice: Designing and Executing Your Validation Protocol

Within the stringent framework of current Good Manufacturing Practice (cGMP), the Validation Master Plan (VMP) serves as the foundational document ensuring that all aspects of a regulated manufacturing process are well-established, documented, and controlled to guarantee consistent product quality [31]. For researchers and drug development professionals working with advanced therapies like human induced pluripotent stem cells (hiPSCs), the VMP provides the critical roadmap for qualifying facilities, equipment, and processes, and importantly, for validating essential analytical methods such as cell counting [19] [7]. This guide objectively compares cell counting methods, situating their validation within the comprehensive context of the VMP and the analytical standards of ICH Q2(R1), providing the experimental data and protocols necessary for robust, compliant implementation [18] [32] [12].

What is a Validation Master Plan (VMP)?

The Validation Master Plan (VMP), also known as a Master Validation Plan, is a high-level strategic document that functions as a central guide and roadmap for an organization's entire validation program [31] [33] [34]. It outlines the overall philosophy, approach, and activities required to demonstrate that facilities, equipment, systems, and manufacturing processes are fit for their intended purpose and capable of consistently delivering a high-quality product [33] [35].

In regulated industries, consistency and quality are mandatory, not optional. The VMP is the document that proves control over manufacturing operations to regulatory agencies like the FDA and EMA [33]. Although the FDA's 21 CFR part 210 and 211 do not formally mandate a VMP, it is often the first document an FDA inspector requests [34]. Within the European Union, a VMP is a formal regulatory requirement outlined in the EU GMP Guide, Annex 15 [34] [35]. The VMP eliminates ambiguity by forcing internal stakeholders to agree upon a unified validation strategy, thereby demonstrating a proactive, organized approach to compliance and quality [31] [34].

The Critical Link Between the VMP and Analytical Method Validation

The VMP provides the overarching structure under which specific validation activities, such as Process Validation, Cleaning Validation, and Analytical Method Validation, are planned and executed [34]. For cell-based therapies like hiPSCs, the cell count is a potency test, directly indicating the product's therapeutic dose [18]. Therefore, validating the cell counting method is not an isolated activity; it is an integral part of the control strategy for an Advanced Therapy Medicinal Product (ATMP) [19] [7]. The VMP dictates the framework for this validation, ensuring it complies with cGMP regulations and relevant guidelines, such as ICH Q2(R1) [19] [7]. This integrated approach paves the way for all cGMP facilities pursuing the manufacturing of clinically relevant cell therapies [19].

Core Components of a Validation Master Plan

A robust VMP is structured around several key components that together create a comprehensive and defensible validation program.

Validation Policy and Objectives: This section articulates the company's philosophy and commitment to validation, setting the tone for the entire document and showing regulators that quality is built into the company culture [33] [34].

Organizational Structure and Responsibilities: Clarity of roles is crucial. This component defines the structure of the validation team and outlines specific duties, from senior management providing oversight to Quality Assurance approving protocols and reports [31] [34] [35]. The team typically includes representatives from Quality Assurance, Production, Quality Control, Engineering, and Validation [34].

Facility, System, and Process Summary: The VMP provides a summary of all facilities, systems, equipment, and processes to be validated, often using a matrix to identify the required level of qualification (e.g., DQ, IQ, OQ, PQ) and validation (Process, Cleaning, Computer System) for each item [34] [35].

Validation Strategies: This is the "how" section, describing the specific methodologies for different validation types, including Process Validation, Equipment/System Qualification, Cleaning Validation, and Computer System Validation (CSV) [33] [34]. The strategy should be risk-based, focusing efforts on aspects most critical to product quality and patient safety [31] [34].

Documentation Standards and Protocols: This section establishes the rules for all validation paperwork, specifying the formats for protocols and reports and outlining the review and approval process [33] [34]. A validation protocol is a detailed plan stating how a specific validation will be conducted, including objectives, responsibilities, test methods, and acceptance criteria [34].

Change Control and Ongoing Management: The VMP is a living document. A change management process must be defined to handle revisions to the plan or validated states, ensuring the system remains in a validated state throughout its lifecycle [35].

Analytical Method Validation for Cell Counting: ICH Q2(R1) Framework

For a cell counting method to be used in the cGMP release of a drug product, it must be rigorously validated to prove it is fit for its intended purpose. The ICH Q2(R1) guideline, "Validation of Analytical Procedures: Text and Methodology," provides the internationally harmonized framework for this validation [12]. It defines the key performance characteristics that must be evaluated [32] [12].

Key Validation Parameters and Acceptance Criteria

The following parameters, as defined by ICH Q2(R1), are typically assessed for a quantitative cell counting assay [18] [32]:

- Accuracy: Expresses the closeness of agreement between the value found and a reference value. For cell counting, this is often demonstrated by comparing a new method against a reference method like the Bürker hemocytometer [18].

- Precision: This includes repeatability (intra-assay precision under the same conditions) and intermediate precision (variation between different analysts, instruments, or days). It is often measured using the percent relative standard deviation (%RSD) [32].

- Specificity: The ability to unequivocally measure the analyte (e.g., viable cells) in the presence of other components like cell debris or impurities [32].

- Linearity and Range: The ability to obtain results directly proportional to the analyte concentration within a specified range. The range is the interval between the upper and lower levels of analyte that have been demonstrated to be determined with suitable levels of precision, accuracy, and linearity [18].

- Robustness: A measure of the method's reliability when small, deliberate variations in method parameters (e.g., incubation time, dye concentration) are introduced [32].

Comparative Analysis of Cell Counting Methods

The choice of cell counting method involves a critical balance between regulatory acceptance, precision, speed, and practicality in a GMP environment. The following table provides a structured, data-driven comparison of three common methods.

Table 1: Objective Comparison of Cell Counting Methods in a GMP Context

| Feature | Bürker Hemocytometer (Manual) | Fast Read 102 (Disposable) | NucleoCounter NC-100 (Automated) |

|---|---|---|---|

| Regulatory Status | Reference method described in the European Pharmacopoeia [18] | Validated alternative method [18] | Validated alternative method [19] [7] |

| Principle | Bright-field microscopy with trypan blue exclusion [18] | Bright-field microscopy with trypan blue exclusion [18] | Fluorescence microscopy with AO/DAPI stains [19] |

| Precision (CV%) - Viable Cells | Not specified (operator-dependent) | <5% (intra-operator) [18] | Higher than manual method [19] [7] |

| Precision (CV%) - Total Cells | Not specified (operator-dependent) | <10% (intra-operator) [18] | Higher than manual method [19] [7] |

| Key Advantage | Regulatory reference standard [18] | Disposable; avoids cleaning validation and cross-contamination [18] | High precision and speed; reduced operator dependency [19] [7] |

| Key Disadvantage | Operator-dependent and time-consuming [19] [18] | Still a manual process, though simpler [18] | Software may require 21 CFR Part 11 compliance [18] |

| GMP/GLP Suitability | Suitable, but prone to human error and requires extensive training | Highly suitable, single-use simplifies compliance [18] | Highly suitable for high-throughput cGMP manufacturing [19] |

Abbreviations: CV%, Coefficient of Variation Percentage; AO, Acridine Orange; DAPI, 4',6-diamidino-2-phenylindole.

Experimental Protocols for Cell Counting Method Validation

To ensure reproducibility and regulatory acceptance, the validation of a cell counting method must follow a detailed, pre-approved protocol. The workflows below and the subsequent reagent toolkit outline the critical steps for a comparative validation study.

Workflow for Validating an Alternative Cell Counting Method

Detailed Experimental Methodology

The validation of an automated or disposable counting method typically follows a comparative approach against the pharmacopeial reference method.

Cell Sample Preparation: As demonstrated in validations for hiPSCs and mesenchymal stem cells (MSCs), the process begins with the preparation of cell samples relevant to the therapy [19] [18]. For hiPSCs, this involves culture and expansion under defined conditions. Mononuclear cells (MNCs) can be isolated from peripheral blood using a density gradient centrifugation (e.g., Hystopaque at 1.077 g/ml) [18].

Sample Dilution and Range Finding: A critical step is to prepare a series of serial dilutions of the cell sample to establish the linear range of the counting method. One study established that a dilution range between 1:8 and 1:128 was optimal for obtaining a linear slope value close to 1 [18].

Accuracy and Precision Testing: Two or more operators perform multiple counts of the same homogeneous sample using both the reference method (Bürker hemocytometer) and the alternative method (e.g., NucleoCounter NC-100 or Fast Read 102) [19] [18]. Accuracy is determined by the closeness of agreement between the two methods. Precision (repeatability and intermediate precision) is calculated from the series of measurements, expressed as the average, standard deviation, and coefficient of variation (CV%) [18]. Acceptance criteria, such as a CV of less than 10% for total cells and less than 5% for viable cells, should be pre-defined [18].

The Scientist's Toolkit: Essential Reagents and Materials

Table 2: Key Research Reagent Solutions for Cell Counting Validation

| Item | Function/Application | Example from Literature |

|---|---|---|

| Bürker Hemocytometer | Reference method for manual cell counting; a ruled glass chamber for microscopic cell enumeration [19] [18]. | Described in European Pharmacopoeia as a standard [18]. |

| NucleoCounter NC-100 | Automated, fluorescence-based cell counter; used for validated, high-precision counting in hiPSC manufacturing [19] [7]. | Validated for cGMP manufacturing of hiPSCs, showing high precision [19]. |

| Fast Read 102 Slide | A disposable cell counting chamber; eliminates cleaning and cross-contamination risks in GMP [18]. | Validated as an accurate and precise alternative to the Bürker chamber [18]. |

| Trypan Blue Dye | A vital dye used to distinguish viable (unstained) from non-viable (blue) cells in bright-field methods [18]. | Used for viability assessment in the validation of the Fast Read 102 method [18]. |

| Acridine Orange (AO) / DAPI | Fluorescent stains used in the NucleoCounter system to label total and dead cells, enabling automated viability calculation [19]. | Part of the fluorescence imaging-based system [19]. |

| Cell Culture Media | Provides the nutrient environment for growing and maintaining cell lines like hiPSCs and MSCs prior to counting [18]. | E.g., MesenCult Proliferation Kit for MSCs; specific media for hiPSCs [18]. |

| Density Gradient Medium | Used to isolate specific cell populations, such as mononuclear cells (MNCs), from complex mixtures like whole blood [18]. | E.g., Hystopaque at 1.077 g/ml density [18]. |

The journey from research to clinically applicable cell therapies is paved with rigorous quality controls, centrally guided by a Validation Master Plan. This document is not merely a regulatory formality but a powerful business tool that orchestrates all validation activities, including the critical validation of analytical methods like cell counting [31] [33]. As demonstrated, modern automated and disposable counting methods can be successfully validated per ICH Q2(R1) to show superior precision and efficiency compared to traditional manual methods, making them highly suitable for the high-stakes environment of cGMP manufacturing [19] [18] [7]. For scientists and drug developers, a well-constructed VMP, supported by scientifically sound and thoroughly documented method validations, is indispensable for ensuring that transformative advanced therapies are consistently safe, pure, and efficacious for patients.

In the field of pharmaceutical development and advanced therapy manufacturing, the reliability of analytical methods is non-negotiable. For cell counting—a critical potency test that determines product dose—method validation under Good Manufacturing Practice (GMP) guidelines provides this assurance [18]. The International Council for Harmonisation (ICH) Q2(R1) guideline forms the bedrock of this process, outlining the key parameters that must be demonstrated to prove a method is suitable for its intended use [18] [19]. This guide provides a detailed, step-by-step framework for validating three of these essential parameters—Accuracy, Precision, and Specificity—within the context of cell counting for GMP-compliant research and drug development.

The Foundation: ICH Q2(R1) and GMP

The validation of any analytical method, including cell counting, must be structured around a formal validation master plan compliant with regulatory standards [18]. The ICH Q2(R1) guideline, "Validation of Analytical Procedures," is the internationally accepted standard for this purpose [36]. It defines the various validation characteristics and provides a clear framework for their demonstration.

For Advanced Therapy Medicinal Products (ATMPs) and other cell-based products, manufacturing must comply with GMP principles, and the quality control cycle must ensure product safety and efficacy from raw materials to final release [18] [19]. In this context, the cell count is not merely a number; it is a potency test, directly linked to the product's therapeutic dose and, therefore, requires rigorous validation [18]. The objective is to generate documented evidence that the cell counting method is consistently accurate, precise, and specific.

Core Definitions: Accuracy, Precision, and Specificity

Understanding the precise definitions of these parameters is the first step toward their proper validation.

- Accuracy is defined as the closeness of agreement between the measured value and a value accepted as a conventional true value or an accepted reference value [37] [18] [36]. It measures the trueness of your results, often expressed as a percentage recovery of the known value [36].

- Precision expresses the closeness of agreement (degree of scatter) between a series of measurements obtained from multiple samplings of the same homogeneous sample under the prescribed conditions [37] [18]. It is considered at three levels:

- Repeatability (Intra-assay Precision): Precision under the same operating conditions over a short interval of time [18] [36].

- Intermediate Precision: Precision within a single laboratory, accounting for variations like different analysts, different instruments, and different days [36].

- Reproducibility: Precision between different laboratories, often assessed for method standardization [36].

- Specificity is the ability of the method to assess the analyte unequivocally in the presence of other components that may be expected to be present, such as impurities, degradants, or sample matrix [37] [36]. A specific method should yield results for the target analyte only, free from interference [37].

The relationship between accuracy and precision is best understood visually: a method can be precise (tightly clustered results) but not accurate (clustered away from the true value), or accurate (centered on the true value) but not precise (widely scattered). The goal is to be both accurate and precise.

Experimental Protocols for Validation

This section outlines detailed experimental methodologies for validating accuracy, precision, and specificity in cell counting.

Experimental Protocol for Accuracy

The accuracy of a cell counting method is typically validated by comparison against a reference method [18] [19].

Step-by-Step Procedure:

- Obtain a Reference Standard: Use a sample of cells with a known concentration, determined using a reference method. The Bürker chamber (or other hemocytometers like Neubauer) is often considered the reference method as described in the European Pharmacopoeia [18] [19].

- Prepare Serial Dilutions: Create a series of dilutions of the cell sample to cover a defined range of concentrations (e.g., low, mid, and high) [37].

- Analyze with Test Method: Count the cells in each dilution using the method being validated (e.g., the disposable Fast Read 102 device or an automated system like the NucleoCounter NC-100) [18] [19].

- Calculate % Accuracy: For each known concentration, calculate the accuracy using the formula: % Accuracy = (Measured Value / Known Value) * 100 [36].

- Establish Acceptance Criteria: The method is considered accurate if the mean recovery percentage at each concentration level falls within a pre-defined range (e.g., 80-120%). Coefficients of variation (CV) of less than 10% are often used as a benchmark [18].

Experimental Protocol for Precision

Precision is validated by repeatedly measuring the same homogeneous sample and calculating the variability.

Step-by-Step Procedure:

- Prepare a Homogeneous Cell Suspension: Ensure the sample is well-mixed to guarantee homogeneity.

- Repeatability (Intra-assay Precision):

- A single analyst performs multiple cell counts (e.g., n=6 or more) of the same sample in a single session using the same instrument [36].

- Calculate the average, standard deviation, and coefficient of variation (CV%) for the results.

- Intermediate Precision:

- Establish Acceptance Criteria: The precision is acceptable if the CV% is below a specified threshold. For cell counts, a CV of less than 10% for total cells and under 5% for viable cells has been successfully used in validation studies [18].

Experimental Protocol for Specificity

Specificity ensures that the cell count is not influenced by other components in the sample matrix.

Step-by-Step Procedure:

- Prepare a Matrix Blank: Prepare a sample that contains all the components of the sample except for the target cells (e.g., culture medium with all additives but no cells) [37].

- Analyze the Blank: Perform the cell counting procedure on the matrix blank.

- Analyze the Test Sample: Perform the count on the actual cell sample.

- Evaluate for Interference: The method is considered specific if no significant signal is detected in the matrix blank, while a clear signal is present in the test sample [37]. This demonstrates that the method is not detecting non-cellular components as false positives.

Comparative Data: Manual vs. Automated Cell Counting

The following tables summarize experimental validation data comparing traditional manual counting with emerging automated methods, as documented in published studies.

Table 1: Summary of Validated Cell Counting Methods in GMP Research

| Counting Method | Key Feature | Validation Parameters Demonstrated | Reported Performance (from cited studies) |

|---|---|---|---|

| Bürker Chamber [18] [19] | Reference method; glass, non-disposable | Accuracy (as reference), Precision, Specificity | Considered the reference standard, but operator-dependent and time-consuming [19]. |

| Fast Read 102 [18] | Disposable slide; avoids washing | Accuracy, Precision (intra/inter-operator), Linearity, Range | CV <10% (total cells); CV <5% (viable cells). Meets acceptance criteria for GMP [18]. |

| NucleoCounter NC-100 [19] | Automated, fluorescence-based | Accuracy, Specificity, Intra-/Inter-operator Reproducibility, Range, Linearity | Higher precision than manual method; faster; validated for use with hiPSCs in cGMP [19]. |

Table 2: Comparison of Performance Metrics in Validation Studies

| Validation Parameter | Manual Hemocytometer (e.g., Bürker) | Automated System (e.g., NucleoCounter) |

|---|---|---|

| Precision (CV%) | Subject to higher operator variability [19]. | Higher precision demonstrated; less dependent on operator [19]. |

| Intermediate Precision | Requires multiple analysts to validate [18]. | Validated to show high reproducibility between operators [19]. |

| Specificity | Relies on analyst's ability to distinguish cells from debris. | Often uses fluorescent dyes (e.g., for viability) for enhanced specificity [19]. |

| Throughput | Time-consuming [19]. | Rapid, enabling higher throughput in quality control [19]. |

The Scientist's Toolkit: Essential Research Reagents & Materials

The following materials are essential for executing the validation protocols described above.

Table 3: Essential Materials and Reagents for Cell Counting Validation

| Item | Function / Description | Example Use in Validation |

|---|---|---|

| Cell Counting Chamber | Device for microscopically visualizing and counting cells. | Bürker chamber as a reference method [18]; disposable Fast Read 102 as an alternative [18]. |

| Vital Dye (e.g., Trypan Blue) | Stains non-viable cells with compromised membranes. | Used to assess cell viability simultaneously with total cell count, a key aspect of potency [18]. |

| Lysing Solution (e.g., Tuerk Solution) | Lyses red blood cells in samples like whole blood or bone marrow. | Validates specificity and accuracy in complex matrices by removing interfering cells [18]. |

| Automated Cell Counter | Instrument that automates sample preparation and/or analysis. | NucleoCounter NC-100 system, validated for higher precision and speed in cGMP settings [19]. |