Cell Expansion Protocols: A Strategic Guide to Autologous vs. Allogeneic Approaches for Researchers

This article provides a comprehensive analysis of cell expansion protocols for autologous and allogeneic therapies, tailored for researchers, scientists, and drug development professionals.

Cell Expansion Protocols: A Strategic Guide to Autologous vs. Allogeneic Approaches for Researchers

Abstract

This article provides a comprehensive analysis of cell expansion protocols for autologous and allogeneic therapies, tailored for researchers, scientists, and drug development professionals. It covers foundational principles, from defining the core immunological and logistical differences between using a patient's own cells versus a donor's. The scope extends to detailed methodological workflows, critical troubleshooting strategies for manufacturing and scaling, and a direct comparative validation of safety, efficacy, and commercial viability. By synthesizing recent clinical advancements and current industry challenges, this guide aims to inform strategic decision-making in the development of advanced therapy medicinal products (ATMPs).

Core Concepts: Defining Autologous and Allogeneic Cell Sources and Their Fundamental Differences

The field of advanced therapies is fundamentally divided into two distinct manufacturing paradigms: patient-specific therapies and off-the-shelf therapies. This distinction is crucial for researchers and drug development professionals as it dictates every aspect of therapeutic development, from manufacturing strategy and supply chain logistics to clinical implementation and commercial viability. Patient-specific therapies (also referred to as autologous when using the patient's own cells) are customized for each individual patient, where material comes from one patient or donor, is processed, and is returned to the same patient (or a matched patient in the case of a donor source) [1]. In contrast, off-the-shelf therapies (often allogeneic, derived from healthy donors) are manufactured in large batches from a single donor source and can be administered to multiple patients, offering the advantage of immediate availability [1] [2].

The choice between these paradigms carries significant implications for manufacturing scalability, cost structure, and therapeutic application. For patient-specific therapies, scale-out is required to increase manufacturing capacity, where the patient-scale process must be efficiently repeated for each patient. For off-the-shelf therapies, scale-up is the key strategy, where a larger process that yields doses for many patients is developed to achieve economies of scale [1]. Understanding these fundamental differences is essential for designing appropriate expansion protocols and manufacturing systems for advanced therapeutic medicinal products (ATMPs).

Manufacturing Workflows and Economic Considerations

Comparative Manufacturing Processes

The manufacturing workflows for patient-specific versus off-the-shelf therapies differ significantly in their starting materials, production timelines, and quality control approaches. Patient-specific therapies begin with cell collection from an individual patient, typically via leukapheresis or tissue biopsy, followed by cell processing, genetic modification (if applicable), expansion, and final formulation before being returned to the same patient [2]. This process must be repeated for each individual patient, creating substantial logistical challenges including cold-chain maintenance, strict time constraints, and the critical need for end-to-end traceability and chain-of-identity [3].

Off-the-shelf therapies follow a fundamentally different manufacturing model. These therapies begin with cells from a qualified healthy donor, which are used to establish a master cell bank system [4]. Through a scaled-up manufacturing process, potentially using bioreactors and other large-scale culture technologies, a single manufacturing run can produce hundreds or even thousands of therapeutic doses [5] [2]. These doses can be cryopreserved and stored until needed, creating an inventory of available treatments. This approach significantly simplifies supply chain logistics and eliminates the waiting period between patient identification and treatment availability.

Economic and Scalability Analysis

The manufacturing cost structures for these two paradigms differ substantially, with significant implications for commercial viability and patient access. A detailed analysis of manufacturing costs reveals that patient-specific therapies incur considerably higher production expenses due to individualized processing and testing requirements.

Table: Comparative Manufacturing Cost Analysis for Cell Therapies

| Cost Component | Patient-Specific/Autologous Therapy | Off-the-Shelf/Allogeneic Therapy |

|---|---|---|

| Donor Screening & Testing | £990–1320 (US$1590–2110) per patient [4] | £10–20 (US$16–32) per dose (cost spread across many patients) [4] |

| Release Testing | £300–500 (US$480–800) per batch (each patient is a batch) [4] | £3–5 (US$4.8–8) per dose (batch yields ~100 doses) [4] |

| Total Manufacturing Cost per Dose | £2260–3040 (US$3630–4890) [4] | £930–1140 (US$1490–1830) [4] |

| Scalability Approach | Scale-out (repeating process for each patient) [1] | Scale-up (larger batches for multiple patients) [1] |

The economic advantage of off-the-shelf therapies is primarily driven by the ability to amortize donor screening and release testing costs across many treatment doses [4]. For patient-specific therapies, each patient requires their own donor screening and testing, and each patient's product constitutes an individual batch requiring separate release testing. This fundamental difference in manufacturing architecture makes off-the-shelf therapies potentially more economically sustainable for widespread clinical application, particularly for common conditions.

Clinical Applications and Efficacy Data

Therapeutic Performance Across Indications

Both patient-specific and off-the-shelf approaches have demonstrated clinical efficacy across various indications, though with different risk-benefit profiles and implementation challenges. In orthopedic applications, a 2025 study comparing patient-specific versus off-the-shelf unicompartmental knee arthroplasty (UKA) found that while patient-specific implants showed superior patient-reported outcomes (KOOS total score: 89 vs. 76, p=0.020), both groups demonstrated similar biomechanical function during gait analysis [6]. Notably, neither approach fully restored normal knee biomechanics compared to healthy controls, suggesting compensatory mechanisms at adjacent joints [6].

In oncology, autologous CAR-T therapies have demonstrated remarkable efficacy for hematological malignancies, with response rates of 35-40% in difficult-to-treat populations [2]. However, these patient-specific therapies face significant challenges including manufacturing failures in 2-10% of cases, time-consuming production processes (typically three weeks), and T-cell exhaustion in heavily pre-treated patients [2]. These limitations have driven the development of allogeneic, off-the-shelf alternatives that can be manufactured from healthy donor cells and made immediately available to patients.

Table: Clinical Comparison of Autologous vs. Allogeneic CAR-T Therapies

| Parameter | Autologous (Patient-Specific) CAR-T | Allogeneic (Off-the-Shelf) CAR-T |

|---|---|---|

| Source Cells | Patient's own T-cells [2] | Healthy donor PBMCs, umbilical cord blood, or iPSCs [2] |

| Manufacturing Time | ~3 weeks [2] | Pre-manufactured, available immediately [2] |

| Key Challenges | T-cell exhaustion, manufacturing failures (2-10%), time delays [2] | Graft-versus-host disease (GvHD), host-versus-graft rejection, limited persistence [2] |

| Manufacturing Failure Rate | 2-10% of cases [2] | Minimal (uses healthy donor cells) |

| Therapeutic Cost | ~$500,000 per dose [5] | Significantly lower (1% of autologous cost potential) [5] |

Recent clinical data for allogeneic approaches show promising results. In the phase 1 TRAVERSE trial for renal cell carcinoma, an allogeneic CAR-T product (ALLO-316) demonstrated a 25% confirmed objective response rate in heavily pre-treated patients, with no graft-versus-host disease reported [5]. Similarly, advances in CAR-NK cell therapies, which naturally have a lower risk of GvHD, are showing promise as off-the-shelf alternatives [5].

Manufacturing and Scalability Challenges

The manufacturing of both patient-specific and off-the-shelf therapies faces significant technical challenges that impact product quality, consistency, and scalability. For patient-specific therapies, the high variability of starting material from different patients represents a major hurdle. Cells from donors exhibit varying metabolic profiles and capabilities, yet current manufacturing processes often lack the adaptability to normalize these differences [3]. Additionally, maintaining consistent product quality while manufacturing individual batches for each patient requires sophisticated tracking systems and significant quality control resources.

For off-the-shelf therapies, the primary manufacturing challenge lies in scaling up production while maintaining consistent product characteristics and potency. As noted in recent analyses, "the biggest near-term challenge in the cell therapy industry continues to be the high cost of manufacturing doses, particularly with autologous products" [3]. There is a growing recognition that "legacy manufacturing processes, which remain the leading driver of high therapeutic costs" must be replaced with more efficient, automated systems [3]. Both paradigms face challenges related to the need for automated cell culturing to achieve commercial-scale manufacturing, deliver economies of scale, produce more consistent products, and reduce contamination risks [4].

Experimental Protocols

Protocol for Patient-Specific Therapy Manufacturing

Title: Manufacturing Protocol for Autologous CAR-T Cell Therapy

Principle: This protocol outlines the manufacturing process for patient-specific chimeric antigen receptor (CAR) T-cell therapy, which involves genetically modifying a patient's own T-cells to express CARs targeting specific tumor antigens.

Materials:

- Leukapheresis system for cell collection

- Ficoll-Paque PLUS for peripheral blood mononuclear cell (PBMC) separation

- Activation reagents: Anti-CD3/CD28 antibodies

- Viral vector (lentiviral or retroviral) encoding CAR construct

- Cell culture media: X-VIVO 15 or TexMACS with cytokines (IL-2, IL-7, IL-15)

- Bioreactor system for cell expansion (e.g., WAVE, G-Rex)

- Quality control assays: Flow cytometry, qPCR, sterility testing

Procedure:

- Patient Leukapheresis: Perform leukapheresis on the patient to collect peripheral blood mononuclear cells (PBMCs). Process within 24-36 hours of collection.

- PBMC Separation: Isolate PBMCs using density gradient centrifugation with Ficoll-Paque PLUS (400 × g, 30 min, room temperature).

- T-cell Activation: Resuspend PBMCs in complete media supplemented with anti-CD3/CD28 antibodies (1 μg/mL each) and IL-2 (100 IU/mL). Culture at 37°C, 5% CO₂ for 24-48 hours.

- Viral Transduction: Transfer activated T-cells to retronectin-coated plates at 1×10⁶ cells/mL. Add viral vector at multiplicity of infection (MOI) of 5-10. Centrifuge at 2000 × g for 90 min at 32°C (spinoculation).

- Cell Expansion: Transfer transduced cells to bioreactor systems. Culture in complete media with IL-2 (100 IU/mL) for 10-14 days, maintaining cell density between 0.5-2×10⁶ cells/mL.

- Harvest and Formulation: Harvest cells when target expansion is achieved (typically 10-14 days). Wash and formulate in infusion buffer.

- Quality Control: Perform release testing including viability (>70%), sterility, mycoplasma, endotoxin, identity (flow cytometry for CAR expression), and potency.

- Cryopreservation and Shipping: Cryopreserve in 5-10% DMSO at controlled rate freezing. Ship to clinical site in vapor phase liquid nitrogen dry shippers.

Notes: The entire process typically takes 3-4 weeks from leukapheresis to product release. Each patient's product is manufactured as an individual batch, requiring separate quality control testing and documentation.

Protocol for Off-the-Shelf Therapy Manufacturing

Title: Manufacturing Protocol for Allogeneic CAR-NK Cell Therapy

Principle: This protocol describes the manufacturing process for off-the-shelf CAR-natural killer (NK) cell therapy using umbilical cord blood-derived NK cells from healthy donors, enabling large-scale production for multiple patients.

Materials:

- Umbilical cord blood units from screened donors

- Ficoll-Paque PLUS for mononuclear cell separation

- NK cell activation reagents: IL-2, IL-15, IL-21

- NK cell expansion media: StemSpan with FBS and cytokines

- GMP-compliant bioreactor system (e.g., CliniMACS Prodigy)

- CRISPR/Cas9 system for genetic modification (where applicable)

- Cryopreservation solution with DMSO

Procedure:

- Donor Screening and Cell Source Preparation: Screen healthy donors and obtain umbilical cord blood units. Process within 24 hours of collection.

- Mononuclear Cell Separation: Isolate mononuclear cells using density gradient centrifugation with Ficoll-Paque PLUS (400 × g, 30 min, room temperature).

- NK Cell Enrichment: Isolate NK cells using immunomagnetic selection (CD3 depletion followed by CD56 positive selection). Assess purity by flow cytometry (>90% CD56⁺CD3⁻).

- Genetic Modification: Activate NK cells with IL-2 (1000 IU/mL) and IL-15 (10 ng/mL) for 24 hours. Transduce with CAR-encoding viral vector (lentiviral) at MOI 10-20 using spinoculation.

- Large-Scale Expansion: Seed CAR-NK cells in GMP-compliant bioreactor at 0.2×10⁶ cells/mL in NK cell expansion media with IL-2 (1000 IU/mL) and IL-15 (10 ng/mL). Culture for 14-21 days, feeding as needed.

- Harvest and Formulation: Harvest cells when target expansion is achieved (typically 1000-fold expansion). Wash and concentrate cells.

- Quality Control and Batch Release: Perform comprehensive testing including viability, sterility, mycoplasma, endotoxin, CAR expression, cytotoxicity assays, and copy number analysis for viral integration.

- Cryopreservation and Banking: Cryopreserve in multiple aliquots (1-10×10⁷ cells/vial) using controlled-rate freezing. Store in master and working cell banks.

Notes: A single manufacturing run can produce 100-1000 doses for multiple patients. Extensive characterization of master cell banks is required, including identity, purity, potency, and stability studies.

The Scientist's Toolkit: Essential Research Reagents

Table: Key Research Reagents for Cell Therapy Development

| Reagent/Category | Function | Examples/Applications |

|---|---|---|

| Cell Separation Media | Isolation of mononuclear cells from whole blood or tissue samples | Ficoll-Paque PLUS for density gradient centrifugation [2] |

| T-cell Activation Reagents | Activation and stimulation of T-cells prior to genetic modification | Anti-CD3/CD28 antibodies (TransAct, Dynabeads) [2] |

| Gene Delivery Vectors | Introduction of genetic material (CAR constructs) into target cells | Lentiviral vectors, retroviral vectors, CRISPR/Cas9 systems [2] |

| Cytokines and Growth Factors | Promotion of cell expansion, survival, and specific differentiation | IL-2, IL-7, IL-15, IL-21 for T-cell/NK cell expansion [2] |

| Cell Culture Media | Support of cell growth, expansion, and maintenance during manufacturing | X-VIVO 15, TexMACS, StemSpan serum-free media [2] |

| Cell Selection Systems | Isolation and purification of specific cell populations | Immunomagnetic bead systems (CliniMACS, Dynabeads) [2] |

| Analytical Tools | Characterization of cell products and quality control | Flow cytometry, qPCR, ELISA, cytotoxicity assays [2] |

Visualizing Workflows and Decision Pathways

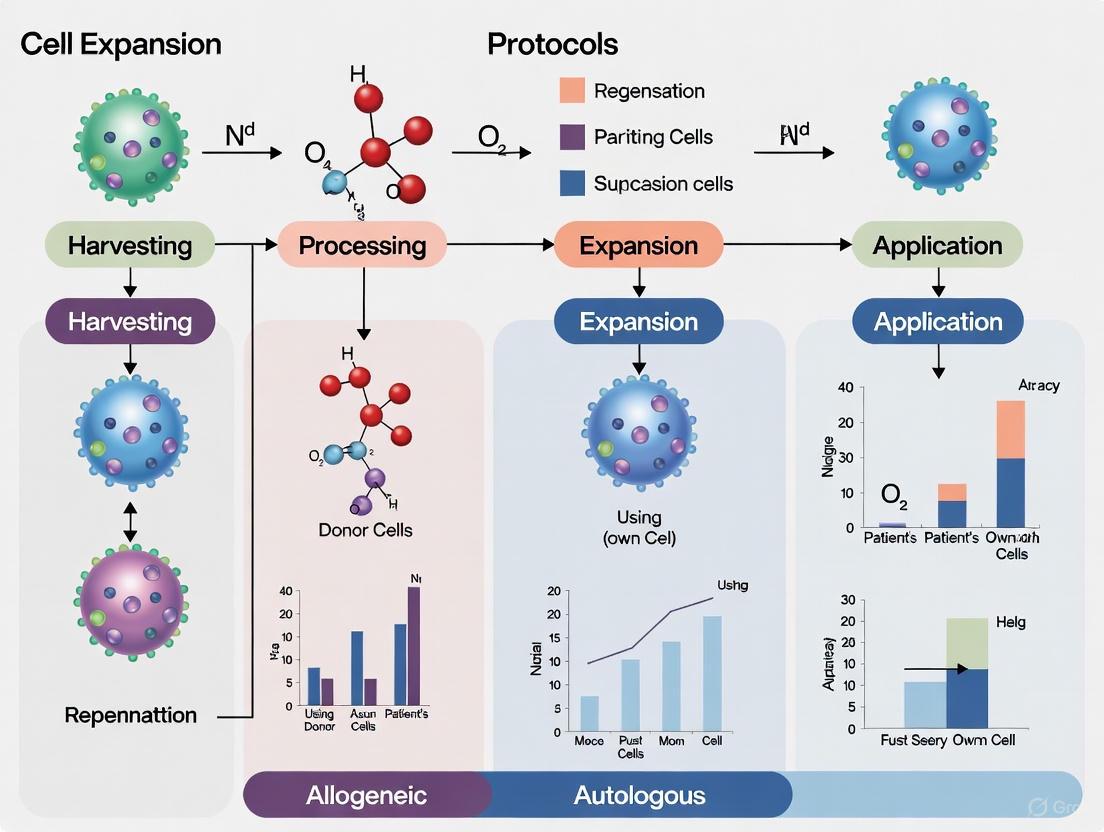

Therapy Manufacturing Workflows

Therapy Selection Decision Pathway

The choice between patient-specific and off-the-shelf therapy paradigms represents a fundamental strategic decision in advanced therapy development, with significant implications for manufacturing, clinical implementation, and commercial viability. Patient-specific therapies offer the advantage of personalized treatments with reduced risk of immune rejection but face challenges in manufacturing scalability and cost control. Off-the-shelf therapies provide immediate availability and potentially lower costs through economies of scale but require sophisticated engineering to address immune compatibility issues.

Future directions in the field will likely focus on overcoming the current limitations of both approaches through technological innovations. For patient-specific therapies, this includes implementing advanced automation to reduce costs and improve consistency [3]. For off-the-shelf therapies, research is focusing on novel engineering strategies to enhance persistence and reduce immunogenicity [5] [2]. The ongoing evolution of both paradigms will continue to expand the therapeutic arsenal available to clinicians and researchers, ultimately enabling more personalized, effective, and accessible treatments for patients across a wide spectrum of diseases.

The development of cell therapies is primarily organized along two distinct pathways: autologous and allogeneic. Each approach leverages fundamentally different biological and manufacturing principles to achieve therapeutic goals. Autologous therapies, which utilize a patient's own cells, capitalize on inherent immune compatibility to avoid rejection, creating a highly personalized but logistically complex treatment [7] [8]. In contrast, allogeneic therapies, derived from healthy donors, pursue scalability through "off-the-shelf" availability, enabling broader patient access but introducing significant immunological challenges [9] [10]. This application note delineates the core advantages, technical requirements, and experimental protocols intrinsic to each modality, providing a framework for researchers to navigate this complex developmental landscape. The critical distinction lies in the cell source, which dictates every subsequent aspect of manufacturing, quality control, and clinical application [7] [11].

Core Advantages and Quantitative Comparison

The Autologous Advantage: Innate Immune Compatibility

The principal strength of autologous cell therapy lies in its biological compatibility. Since the therapeutic product is derived from and reinfused into the same patient, it circumvents the major immunological barriers that plague allogeneic approaches. This eliminates the risk of Graft-versus-Host Disease (GvHD), a potentially life-threatening condition where donor immune cells attack host tissues [7] [8]. Consequently, patients receiving autologous therapies typically do not require concomitant immunosuppressive regimens, sparing them from associated risks of infection, organ toxicity, and other drug-related complications [11]. This inherent self-compatibility also allows for greater in vivo persistence of the therapeutic cells, which is crucial for long-term efficacy, particularly in applications like CAR-T therapy for durable cancer remissions [8] [11].

The Allogeneic Advantage: Manufacturing and Commercial Scalability

Allogeneic cell therapies are defined by their scalability and accessibility. Sourced from healthy donors, these therapies can be manufactured in large, well-characterized batches from a single donor collection, creating an "off-the-shelf" product available for immediate use [9] [12]. This model transforms the treatment timeline, eliminating the weeks-long manufacturing delay associated with autologous processes, which is critical for patients with aggressive diseases [8] [11]. From a development and commercial perspective, the allogeneic approach allows for standardized, centralized manufacturing that leverages economies of scale, potentially reducing the cost per dose and making these therapies more accessible to a wider patient population [7] [12].

Table 1: Quantitative and Qualitative Comparison of Autologous and Allogeneic Cell Therapies

| Characteristic | Autologous Therapy | Allogeneic Therapy |

|---|---|---|

| Cell Source | Patient's own cells [7] [8] | Healthy donor (related or unrelated) [7] [12] |

| Key Advantage | Innate immune compatibility; no GvHD risk [8] [11] | "Off-the-shelf" availability & industrial scalability [9] [12] |

| Primary Challenge | Logistical complexity & high cost of goods [3] [7] | Risk of immune rejection (GvHD) & host-mediated elimination [10] [11] |

| Manufacturing Model | Scale-out (multiple parallel patient-specific batches) [7] | Scale-up (large batches from a single donor) [7] |

| Typical Vein-to-Vein Time | Several weeks [11] | Immediate to a few days [11] |

| Immunosuppression Required | Generally not required [8] | Often required [8] [11] |

| Representative Market Share (2025) | ~84% of cell therapy market [12] | ~16% of cell therapy market [12] |

| Global Market Projection | Projected to grow from USD 10.1B (2025) [13] | Significant growth driven by ~250 products in development [12] |

Experimental Protocols for Cell Expansion

The following protocols outline core expansion workflows for both autologous and allogeneic T-cell therapies, highlighting key process distinctions.

Protocol 1: Autologous CAR-T Cell Expansion from Patient Leukapheresis

Principle: To isolate, activate, genetically modify, and expand a patient's T-cells to create a personalized therapeutic product [8] [14].

Materials:

- Starting Material: Leukapheresis product from the patient.

- Isolation Reagents: Anti-CD3/CD28 magnetic beads or similar for T-cell activation.

- Culture Media: Xeno-free T-cell expansion media, supplemented with IL-2 [14].

- Genetic Modification: Viral vector (e.g., lentivirus) encoding the CAR construct.

- Equipment: Automated cell expansion system (e.g., Terumo BCT's quantum cell expansion system), CO2 incubator, biosafety cabinet [14].

Method:

- Peripheral Blood Mononuclear Cell (PBMC) Isolation: Isolate PBMCs from the leukapheresis product via density gradient centrifugation (e.g., Ficoll-Paque).

- T-Cell Activation and Culture: Seed the PBMCs in a pre-coated bioreactor or culture vessel. Activate T-cells using anti-CD3/CD28 beads in xeno-free expansion media. Incubate at 37°C, 5% CO2 [14].

- Genetic Modification (Day 2-3): Transduce activated T-cells with the CAR-encoding viral vector. Optimize the Multiplicity of Infection (MOI) for maximum efficiency and cell viability.

- Cell Expansion (Day 4-12): Continue culture, feeding with fresh media and cytokines as required. Monitor cell density, viability, and phenotype (e.g., CD3+, CD4+/CD8+ ratio) daily.

- Harvest and Formulation: Once target cell numbers are achieved (typically 10-14 days), harvest cells, remove activation beads, and formulate the final drug product in an appropriate infusion solution.

- Quality Control (QC): Perform release tests, including sterility, mycoplasma, endotoxin, vector copy number, CAR expression, and potency.

Protocol 2: Allogeneic CAR-NK Cell Expansion from Master Cell Bank

Principle: To thaw and expand clinically-relevant doses of allogeneic CAR-NK cells from a pre-generated Master Cell Bank derived from cord blood or induced Pluripotent Stem Cells (iPSCs) [9].

Materials:

- Starting Material: Vial from a cGMP-compliant Master Cell Bank of CAR-engineered NK cells.

- Culture Media: Specialized NK cell expansion media (e.g., containing IL-15, IL-21).

- Feeder Cells: Irradiated K562-derived feeder cells expressing membrane-bound cytokines (e.g., 4-1BBL).

- Equipment: Bioreactor (e.g., G-Rex), CO2 incubator, biosafety cabinet.

Method:

- Thaw and Seed: Rapidly thaw a vial of CAR-NK cells from the Master Cell Bank and seed into culture media supplemented with IL-15 in a bioreactor.

- Stimulation and Expansion (Day 1): Add irradiated feeder cells at a specific effector-to-feeder ratio to stimulate robust NK cell proliferation.

- Fed-Batch Culture (Days 2-14): Maintain culture, periodically adding fresh media and cytokines. Monitor cell count, viability, and phenotype (e.g., CD56+, CD3-) closely.

- Harvest and Cryopreservation: Harvest cells when the target yield is reached. Wash and concentrate cells, then cryopreserve in multiple doses using a controlled-rate freezer. This creates the "off-the-shelf" final product inventory [9].

- Quality Control (QC): Perform batch release testing, including sterility, purity, identity, CAR expression, cytotoxicity assays, and checks for residual feeder cells.

Diagram 1: Cell therapy manufacturing workflows.

The Scientist's Toolkit: Essential Research Reagents and Materials

Successful execution of cell expansion protocols requires carefully selected reagents and materials. The following table details key solutions for robust and reproducible results.

Table 2: Key Research Reagent Solutions for Cell Therapy Development

| Reagent/Material | Function/Application | Key Considerations |

|---|---|---|

| Xeno-Free Cell Culture Media | Supports growth and maintenance of T-cells and NK cells ex vivo [14]. | Formulations are often cell-type specific (T-cell vs. NK cell); xeno-free status reduces regulatory risk for clinical use. |

| Magnetic Beads (Anti-CD3/CD28) | Provides artificial antigen-independent T-cell receptor stimulation for T-cell activation and proliferation [14]. | Critical first step in T-cell manufacturing; bead removal is required prior to infusion. |

| Recombinant Human Cytokines (e.g., IL-2, IL-15) | Enhances cell expansion, promotes survival, and can influence final cell phenotype (e.g., memory vs. exhausted T-cells) [14]. | Concentration and timing of cytokine addition are crucial parameters for optimization. |

| Viral Vectors (Lentivirus, Retrovirus) | Delivers genetic payload (e.g., CAR) into target cells for stable expression. | High titer and good manufacturing practice (GMP)-compatible production are essential for clinical translation. |

| Cell Separation Reagents (e.g., Ficoll-Paque) | Isolates PBMCs from whole blood or leukapheresis product via density gradient centrifugation. | A standard, foundational step for preparing starting material from patient or donor apheresis. |

| Cryopreservation Medium | Protects cell viability during freeze-thaw cycles for long-term storage of allogeneic "off-the-shelf" doses or cell banks. | Typically contains DMSO and serum/serum substitutes; controlled-rate freezing is recommended. |

The choice between autologous and allogeneic cell therapy is not a simple binary decision but a strategic one, guided by the therapeutic target, patient population, and commercial vision. The field is rapidly evolving to mitigate the inherent limitations of each platform. For autologous therapies, the focus is on automation, process optimization, and point-of-care manufacturing to reduce vein-to-vein time, control costs, and alleviate logistical burdens [3] [15] [14]. For allogeneic therapies, the primary research frontier is immune evasion, employing gene editing tools like CRISPR/Cas9 to disrupt HLA molecules to prevent host rejection and TCR complexes to prevent GvHD, thereby creating more universal products [10] [8]. A promising future direction involves the development of "hypoimmune" cells from iPSCs, which are engineered to avoid immune detection, potentially offering the scalability of allogeneic products with the compatibility of autologous ones [10] [8]. Ultimately, both modalities will coexist, enabling researchers and clinicians to arm themselves with the most appropriate tool for a given disease.

The development of cell therapies is bifurcated into two principal approaches: autologous, using the patient's own cells, and allogeneic, using cells from healthy donors [11]. Each pathway presents a distinct profile of technical challenges. Autologous therapies are predominantly hampered by complex logistical and manufacturing hurdles arising from their patient-specific nature, while allogeneic therapies face significant immunological barriers that threaten graft survival and efficacy [11] [16]. This application note delineates these core challenges and provides detailed experimental protocols to aid researchers in navigating these critical development pathways. The content is structured to support a broader thesis on cell expansion protocols, providing comparative data and methodological details relevant to scientists and drug development professionals.

Autologous Cell Therapies: Conquering Logistical Complexity

Core Logistical and Manufacturing Hurdles

Autologous cell therapies are fundamentally a "service-based" model, where each individual batch is a unique product for a single patient [11]. This paradigm creates a multifaceted logistical challenge summarized in the table below.

Table 1: Key Logistical Challenges in Autologous Cell Therapy Manufacturing

| Challenge Category | Specific Hurdles | Impact on Development & Therapy |

|---|---|---|

| Product Stability & Timing | Short ex vivo half-life (as little as a few hours); extended turnaround time (several weeks) [11]. | Risks product integrity; delays treatment for patients with worsening prognoses [11]. |

| Supply Chain & Coordination | Complex coordination for collection, manufacturing, and delivery; stringent chain-of-identity and custody requirements [11] [7]. | Logistically demanding process requiring robust digital infrastructure for tracking [11]. |

| Manufacturing Complexity | High level of personalization; variability in starting cell quality due to patient age, disease, and prior treatments [11] [7]. | High cost; batch heterogeneity; difficulties in maintaining consistent quality attributes [11]. |

| Scalability | Scale-out strategy requiring multiple parallel production lines; not amenable to traditional scale-up [7]. | Challenging to treat highly prevalent diseases; high per-dose cost [11] [7]. |

Experimental Protocol: Assessing Patient-Derived Cell Viability and Expansion Potential

The quality of patient-derived starting material is highly variable. This protocol outlines a method to evaluate cellular health and expansion capacity prior to major manufacturing investments.

Objective: To determine the viability, phenotypic composition, and ex vivo expansion potential of patient-derived apheresis material or tissue samples.

Materials:

- Research Reagent Solutions:

- Ficoll-Paque PREMIUM: For density gradient centrifugation to isolate peripheral blood mononuclear cells (PBMCs).

- StemSpan SFEM or similar serum-free medium: Base medium for hematopoietic cell culture [17].

- Cytokine Cocktail (e.g., SCF, TPO, Flt3L): Essential growth factors for HSPC expansion [17].

- Flow Antibody Panel (CD34, CD38, CD45RA, CD90, CD133): For phenotyping hematopoietic stem and progenitor cells (HSPCs) via flow cytometry [17].

- 7-AAD or DAPI: Viability dyes for flow cytometry.

- Pre-Gassed Culture Bags/Plates: For cell culture.

Methodology:

- Cell Isolation: Isolate PBMCs from apheresis product via density gradient centrifugation using Ficoll-Paque. Wash cells twice in PBS.

- Baseline Analysis:

- Viability Count: Use an automated cell counter with a viability stain (e.g., Trypan Blue) to determine total nucleated cell count and viability.

- Phenotypic Analysis: Stain a sample of cells (~1x10^6) with antibodies against CD34, CD133, CD38, CD45RA, and CD90. Include a viability dye. Analyze on a flow cytometer to quantify the proportion of primitive HSPCs (e.g., CD34+CD38lo/–CD45RA–CD90+CD49f+) [17].

- Expansion Culture:

- Seed cells in serum-free medium (e.g., StemSpan SFEM) supplemented with a cytokine cocktail (e.g., SCF, TPO, Flt3L) at a density of 1-2 x 10^5 cells/mL [17].

- Maintain cultures in a humidified incubator at 37°C and 5% CO2 for 7-14 days.

- Perform partial medium exchanges or feed cells every 2-3 days.

- Endpoint Analysis:

- On day 7 and/or 14, perform total cell counts and viability assessment.

- Re-stain cells for the same phenotypic markers to track the maintenance or loss of the HSPC population during culture.

- Calculate fold expansion of total cells and, critically, the specific HSPC population.

Data Interpretation: A successful starting material should show high initial viability (>90%) and contain a sufficient baseline proportion of target cells. Effective expansion protocols will demonstrate a significant fold-increase in the total number of phenotypically defined HSPCs, indicating robustness for downstream manufacturing.

Allogeneic Cell Therapies: Navigating the Immunological Landscape

Core Immunological Risks

Allogeneic cell therapies, while logistically attractive, face a formidable barrier: host immune recognition and rejection. The primary immunological challenges are graft rejection and graft-versus-host disease (GvHD) [11].

The immune response to allogeneic cells is orchestrated through multiple pathways of allorecognition [16] [18]. The innate immune system, particularly Natural Killer (NK) cells, targets and kills cells that lack "self" Major Histocompatibility Complex (MHC) class I molecules, a phenomenon known as the "missing-self" hypothesis [16] [18]. The adaptive immune system is activated via T cells through three principal pathways:

- Direct Pathway: Recipient T cells directly recognize intact donor MHC molecules on the surface of the transplanted cells.

- Indirect Pathway: Recipient antigen-presenting cells (APCs) engulf donor cells, process donor proteins, and present them as peptide fragments on self-MHC molecules to recipient T cells.

- Semi-Direct Pathway: Recipient APCs acquire intact donor MHC molecules from donor cells and present them directly to recipient T cells [16] [18].

These pathways can lead to the destruction of the therapeutic cells by CD8+ cytotoxic T cells and provide help for B cell activation, resulting in alloantibody production [16].

Figure 1: Immunological Pathways in Allogeneic Cell Rejection. Allogeneic cells trigger host immune responses via both innate (NK cell) and adaptive (T cell) mechanisms. T cell activation occurs through direct, indirect, and semi-direct allorecognition pathways, leading to graft rejection and alloantibody production [16] [18].

Experimental Protocol: In Vitro Assessment of Allogeneic T Cell-Mediated Rejection

This protocol utilizes a mixed lymphocyte reaction (MLR) to model T cell-dependent immune responses against allogeneic cell therapy products in a controlled setting.

Objective: To evaluate the potential immunogenicity of an allogeneic cell therapy candidate by measuring its ability to provoke T cell activation and proliferation from allogeneic PBMCs.

Materials:

- Research Reagent Solutions:

- Allogeneic Cell Therapy Candidate: The putative "target" cells (e.g., iPSC-derived cells, MSCs).

- Allogeneic PBMCs: From multiple healthy donors, to serve as "effector" cells.

- RPMI-1640 Complete Medium: Supplemented with L-glutamine, HEPES, and 10% human AB serum.

- Carboxyfluorescein Succinimidyl Ester (CFSE): Cell proliferation dye for tracking effector cell division.

- Flow Antibody Panel (CD3, CD4, CD8, CD25, CD69, CD137): For T cell activation markers.

- ELISA Kits (e.g., IFN-γ, Granzyme B): To measure T cell effector function.

Methodology:

- Cell Preparation:

- Irradiate the allogeneic cell therapy candidate (the "stimulator" cells) to prevent their proliferation while maintaining antigen presentation.

- Isolate PBMCs from a healthy donor (the "responder" cells) that is HLA-mismatched with the therapy candidate. Label PBMCs with CFSE according to standard protocols.

- Co-culture Setup:

- Plate irradiated stimulator cells in a 96-well U-bottom plate.

- Add CFSE-labeled responder PBMCs at various stimulator:responder ratios (e.g., 1:1, 1:10).

- Include controls: responder cells alone (negative control) and responder cells with a mitogen like PHA (positive control).

- Culture for 5-7 days in a humidified incubator at 37°C and 5% CO2.

- Endpoint Analysis:

- Proliferation: Analyze CFSE dilution on a flow cytometer within the CD3+ T cell gate to determine the percentage of T cells that have undergone division.

- Activation: Stain cells for early (CD69) and late (CD25, CD137) T cell activation markers.

- Effector Function: Collect supernatant and measure secreted IFN-γ and Granzyme B by ELISA.

Data Interpretation: A potent allogeneic cell therapy candidate engineered for low immunogenicity should show minimal T cell proliferation and low levels of activation markers and inflammatory cytokines compared to a non-engineered control. This assay provides a pre-clinical screen for the likelihood of immune rejection.

Emerging Strategies and Solution Frameworks

Strategic Approaches to Mitigate Challenges

The field is actively developing strategies to overcome the central challenges for both therapeutic modalities.

Table 2: Solution Frameworks for Autologous and Allogeneic Challenges

| Therapy Type | Core Challenge | Proposed Solutions & Technologies |

|---|---|---|

| Autologous | Logistical & Manufacturing Complexity | Automation & Closed Systems: Reduce manual handling, contamination risk, and vein-to-vein time [7] [19]. Point-of-Care Manufacturing: Decentralize production to reduce transport logistics [11]. Advanced Analytics & Digital Tracking: Robust chain-of-identity and custody management [11]. |

| Allogeneic | Immunological Rejection & GvHD | Gene Editing (CRISPR/Cas9, TALENs): Knock-out HLA molecules to create "universal" cells or delete TCR to prevent GvHD [10] [20]. Overexpression of Immunomodulatory Transgenes: Engineered expression of HLA-E, HLA-G, or CD47 to inhibit NK cells and macrophages [16] [18]. Use of Immune-Privileged Cell Types: Mesenchymal Stem/Stromal Cells (MSCs) and some NK cells have inherent low immunogenicity [11]. |

Protocol: CRISPR-Cas9 Mediated Knockout of HLA Class I in iPSCs for Allogeneic Therapy

This protocol outlines a key genetic engineering strategy to evade T cell-mediated rejection.

Objective: To generate HLA class I-deficient induced pluripotent stem cells (iPSCs) using CRISPR-Cas9 gene editing for use as a universal starting material for allogeneic therapies.

Materials:

- Research Reagent Solutions:

- iPSC Line: A well-characterized, clinically relevant iPSC line.

- CRISPR-Cas9 Ribonucleoprotein (RNP) Complex: Cas9 protein pre-complexed with sgRNAs targeting the B2M gene (essential for HLA class I surface expression).

- Electroporation System (e.g., Neon or Amaxa 4D-Nucleofector): For efficient delivery of RNP into iPSCs.

- Flow Antibody against HLA-A,B,C: To confirm knockout efficiency.

- iPSC Culture Reagents: Essential medium (e.g., mTeSR1), Matrigel or Vitronectin, RevitaCell supplement.

Methodology:

- sgRNA Design and RNP Complex Formation: Design and validate sgRNAs targeting the early exons of the B2M gene. Complex purified Cas9 protein with the sgRNAs to form the RNP complex.

- Cell Preparation and Transfection:

- Culture and passage iPSCs to ensure they are in a log-growth phase and >90% viable.

- Harvest a single-cell suspension of iPSCs and resuspend them in the appropriate electroporation buffer.

- Mix the cell suspension with the pre-formed RNP complex and electroporate using an optimized program.

- Post-Transfection Recovery:

- Immediately transfer electroporated cells to a culture plate containing pre-warmed medium supplemented with RevitaCell.

- Allow cells to recover for 48-72 hours before any further manipulation.

- Clonal Isolation and Screening:

- After recovery, dissociate cells into a single-cell suspension and seed at a very low density for clonal expansion.

- Pick individual colonies and expand them in 96-well plates.

- Screen clones for HLA class I knockout by flow cytometry using an antibody against pan-HLA-A,B,C.

- Confirm the genetic modification in HLA-negative clones by Sanger sequencing or next-generation sequencing of the target locus.

Data Interpretation: Successful execution will yield a panel of clonal iPSC lines with complete loss of HLA class I surface expression. These clones can serve as a universal donor source for deriving various differentiated cell types (e.g., neurons, cardiomyocytes) with reduced immunogenicity. It is critical to subsequently evaluate these cells for susceptibility to NK cell-mediated killing due to the "missing-self" response and consider additional engineering steps (e.g., HLA-E expression) to address this [16] [18].

The development of advanced cell therapies, whether autologous (patient-specific) or allogeneic (donor-derived, "off-the-shelf"), relies critically on the selection of appropriate starting cell sources. The choice of source material fundamentally influences manufacturing scalability, product consistency, and therapeutic efficacy [11]. Peripheral Blood Mononuclear Cells (PBMCs), Induced Pluripotent Stem Cells (iPSCs), and Umbilical Cord Blood (UCB) represent three of the most prominent cell sources, each with distinct biological properties and technological applications.

For allogeneic therapies in particular, these sources offer the potential for scalable, off-the-shelf products that can overcome the time, cost, and manufacturing limitations associated with autologous treatments [9] [2]. This document details the characteristic profiles, experimental protocols, and key reagents for working with these critical cell sources within the context of modern cell therapy development.

The table below summarizes the core characteristics, advantages, and challenges of PBMCs, iPSCs, and Umbilical Cord Blood as starting materials for cell therapy.

Table 1: Comparative Analysis of Primary Cell Sources for Cell Therapies

| Feature | PBMCs (Peripheral Blood Mononuclear Cells) | iPSCs (Induced Pluripotent Stem Cells) | Umbilical Cord Blood (UCB) |

|---|---|---|---|

| Source | Peripheral blood of healthy donors or patients [2] | Reprogrammed somatic cells (e.g., fibroblasts, PBMCs) [21] [22] | Umbilical cord and placenta collected at birth [2] |

| Key Cell Types | T cells, B cells, NK cells, monocytes, dendritic cells [2] | Pluripotent stem cells capable of differentiating into any cell type [22] | Hematopoietic stem cells (HSCs), T cells, NK cells [2] |

| Therapeutic Examples | Allogeneic CAR-T cells [2] | iPSC-derived CAR-NK/T cells, tissue-specific cells for regenerative medicine [9] [2] | Allogeneic CAR-NK cells, hematopoietic stem cell transplantation [2] [5] |

| Major Advantages | - Readily accessible from donors- Established isolation protocols- Contains mature immune effector cells [2] | - Unlimited expansion potential- Genetic engineering flexibility- Can generate any cell type [22] [2] | - Immunologically "antigen-naïve"- Lower alloreactivity & GvHD risk- Low exhaustion marker expression [2] |

| Major Challenges | - Donor-to-donor variability- Risk of GvHD in allogeneic settings [2] | - Genomic instability risk during reprogramming/culture- Tumorigenicity risk from residual undifferentiated cells [21] [23] | - Limited cell numbers per donation- Restricted donor pool availability [2] |

Cell Source Specific Protocols

Protocol: Generation of iPSCs from Somatic Cells

The ability to reprogram somatic cells into pluripotent stem cells has opened new avenues for creating allogeneic cell therapies. The following protocol outlines a non-integrating, Sendai viral vector method for iPSC generation, which is favored for clinical applications due to its "zero-footprint" nature [21].

Principle: Somatic cells are reprogrammed into a pluripotent state through the transient expression of key transcription factors (OCT4, SOX2, KLF4, c-MYC) delivered via non-integrating Sendai viral vectors [21] [22].

Materials:

- Source Cells: Fibroblasts (from skin biopsy) or PBMCs [21].

- Reprogramming Vectors: CytoTune-iPS Sendai Reprogramming Kit (or equivalent), containing SeV vectors for KOS (KLF4, OCT4, SOX2), hc-MYC, and hKLF4.

- Culture Vessels: 6-well plates coated with Matrigel or Vitronectin.

- Media: Appropriate somatic cell medium; Essential 8 or mTeSR1 pluripotent stem cell medium.

- Other Reagents: Dulbecco’s Phosphate Buffered Saline (DPBS) with and without calcium and magnesium, TrypLE Select or Accutase.

Procedure:

- Preparation of Somatic Cells: Culture and expand source somatic cells (e.g., fibroblasts) until 70-90% confluent in a 6-well plate. Ensure cells are healthy and proliferating.

- Viral Transduction:

- Calculate the required Multiplicity of Infection (MOI) for each vector. A typical MOI for fibroblasts is KOS=5, hc-MYC=5, hKLF4=3.

- Thaw viral vectors quickly and dilute in the appropriate somatic cell medium.

- Remove the culture medium from the cells and add the virus-containing medium.

- Incubate cells for 24 hours at 37°C, 5% CO₂.

- Post-Transduction Culture:

- After 24 hours, remove the virus-containing medium, wash cells once with DPBS, and add fresh somatic cell medium.

- Culture the transduced cells for an additional 6 days, changing the medium every other day.

- iPSC Colony Expansion:

- On day 7 post-transduction, dissociate the cells into a single-cell suspension using TrypLE Select or Accutase.

- Plate the cells onto Matrigel-coated 6-well plates in somatic cell medium supplemented with a ROCK inhibitor (e.g., Y-27632).

- The following day, switch the medium to Essential 8 or mTeSR1.

- Change the medium daily. Embryonic stem cell-like colonies should become visible within 1-2 weeks.

- Colony Picking and Characterization:

- Manually pick individual, morphologically good colonies and transfer them to new Matrigel-coated 24-well plates.

- Expand clonal lines and characterize established iPSC lines through:

- Pluripotency Marker Analysis: Immunofluorescence for OCT4, SOX2, NANOG.

- Trilineage Differentiation: Via embryoid body formation to confirm differentiation into ectoderm, mesoderm, and endoderm.

- Karyotype Analysis: To ensure genomic integrity.

- Vector Clearance Testing: Perform PCR to confirm the absence of residual Sendai virus after ~10 passages [21].

Protocol: Isolation of Immune Cell Subsets from PBMCs and UCB

This protocol describes the isolation of mononuclear cells and subsequent enrichment of specific immune effector cells, such as T cells or NK cells, from PBMC and UCB sources for use in therapies like CAR-T or CAR-NK.

Principle: Density gradient centrifugation separates mononuclear cells from whole blood or cord blood. Target cell populations are then isolated from PBMCs/UCB-MNCs using positive or negative selection methods based on antibody-bound magnetic beads.

Materials:

- Source Material: Whole blood (for PBMCs) or umbilical cord blood units (for UCB).

- Separation Medium: Ficoll-Paque PREMIUM or Lymphoprep.

- Isolation Kits: CD3 MicroBeads (for T cell isolation) or CD56 MicroBeads (for NK cell isolation) or relevant negative selection kits.

- Buffers: DPBS, pH 7.2, supplemented with 0.5% Bovine Serum Albumin (BSA) or 1% Human Serum Albumin (HSA) and 2 mM EDTA.

- Equipment: Centrifuge, LS Columns, and a MidiMACS or AutoMACS Separator.

Procedure:

- PBMC/UCB-MNC Isolation:

- Dilute blood or cord blood 1:1 with DPBS (with 2 mM EDTA).

- Carefully layer the diluted blood over Ficoll-Paque in a centrifuge tube (e.g., 15 mL of diluted blood over 12 mL of Ficoll).

- Centrifuge at 400 x g for 30-35 minutes at 20°C with the brake turned off.

- After centrifugation, aspirate the upper plasma layer. Carefully collect the mononuclear cell layer at the interface and transfer it to a new tube.

- Wash cells with DPBS/BSA/EDTA buffer by centrifuging at 300 x g for 10 minutes. Repeat wash twice.

- Magnetic-Activated Cell Sorting (MACS):

- Resuspend the cell pellet in MACS buffer (DPBS, 0.5% BSA, 2mM EDTA) at a concentration of 10⁷ cells per 80 µL.

- Add 20 µL of the appropriate MACS MicroBeads per 10⁷ cells. Mix well and incubate for 15 minutes in the refrigerator (2-8°C).

- Wash cells by adding 10-20x the labeling volume of buffer and centrifuge at 300 x g for 10 minutes.

- Place an LS Column in the magnetic field of the MACS Separator. Prepare the column by applying 3 mL of buffer.

- Resuspend the cell pellet in 500 µL of buffer and apply the cell suspension to the column.

- Collect the unlabeled, flow-through fraction (for negative selection). Wash the column 3 times with 3 mL of buffer.

- Remove the column from the magnet and place it on a collection tube. Pipette 5 mL of buffer onto the column and firmly flush out the magnetically labeled cells using the plunger.

- Cell Analysis and Cryopreservation:

- Count the isolated cells and assess viability using Trypan Blue exclusion.

- Analyze purity by flow cytometry (e.g., check CD3+ percentage for T cells or CD56+ for NK cells).

- For long-term storage, cryopreserve cells in a controlled-rate freezer using cryoprotectant medium (e.g., 90% FBS/10% DMSO) and store in liquid nitrogen vapor phase.

Workflow Visualization

The following diagram illustrates the parallel development pathways for creating allogeneic cell therapies from PBMCs, iPSCs, and Umbilical Cord Blood, highlighting key steps from source material to final product.

Diagram 1: Parallel workflows for developing allogeneic cell therapies from PBMCs, iPSCs, and Umbilical Cord Blood.

The Scientist's Toolkit: Essential Reagents and Materials

Successful cell therapy development depends on a suite of specialized reagents and tools. The table below lists key solutions for critical experimental procedures.

Table 2: Essential Research Reagent Solutions for Cell Therapy Development

| Reagent/Material | Primary Function | Example Protocols & Notes |

|---|---|---|

| Ficoll-Paque | Density gradient medium for isolation of PBMCs and UCB-MNCs from whole blood [2] | PBMC/UCB-MNC Isolation Protocol; critical for obtaining a pure mononuclear cell population. |

| MACS MicroBeads | Magnetic bead-based cell separation for positive or negative selection of specific cell types (e.g., CD3+ T cells, CD56+ NK cells) [2] | Immune Cell Subset Isolation; enables high-purity isolation of target effector cells for engineering. |

| Sendai Virus Vectors | Non-integrating viral vectors for efficient delivery of reprogramming factors (OCT4, SOX2, KLF4, c-MYC) to somatic cells [21] | iPSC Generation Protocol; preferred for clinical-grade iPSC generation due to non-integrating nature. |

| CRISPR/Cas9 System | Precision gene-editing tool for knocking out genes (e.g., TCR, HLA) to reduce allorejection and GvHD in allogeneic products [10] [2] | Genetic Engineering of Allogeneic Cells; used to create universal, hypoimmunogenic cell therapies. |

| Lentiviral Vectors | Integrating viral vectors for stable delivery of transgenes, such as Chimeric Antigen Receptors (CARs), into target cells [2] | CAR Transduction; commonly used for engineering CAR-T and CAR-NK cells from various cell sources. |

| Essential 8 / mTeSR1 | Xeno-free, defined cell culture media optimized for the maintenance and expansion of human pluripotent stem cells, including iPSCs [21] | iPSC Culture; supports feeder-free culture of iPSCs, maintaining pluripotency and genomic stability. |

| Recombinant Human Cytokines (e.g., IL-2, IL-7, IL-15, SCF, FLT-3L) | Proteins that promote the survival, proliferation, and differentiation of hematopoietic and immune cells during culture [2] | Cell Expansion; essential for ex vivo expansion of T cells, NK cells, and hematopoietic progenitors. |

| Matrigel / Vitronectin | Extracellular matrix proteins used as a substrate for coating culture vessels to support adherent cell growth, particularly for iPSCs [22] | iPSC Culture; provides a defined attachment surface for robust pluripotent stem cell growth. |

From Lab to Clinic: Methodological Workflows and Clinical Translation of Expansion Protocols

Autologous cell therapy represents a highly personalized treatment modality where a patient's own cells are harvested, processed, and subsequently re-infused back into the same individual. This approach stands in contrast to allogeneic therapies, which utilize cells from healthy donors. The fundamental advantage of autologous therapy lies in its inherent immunological compatibility; since the cells originate from the patient, the risks of immune rejection and graft-versus-host disease (GvHD) are significantly minimized, eliminating the need for immunosuppressive therapy to support graft survival [8]. This personalized approach is particularly valuable for patients with compromised immune systems and has demonstrated remarkable success in treating hematological malignancies, autoimmune diseases, and degenerative disorders [8] [24].

However, the autologous process presents substantial challenges in manufacturing and logistics. Each patient's treatment constitutes a unique product batch, requiring complex coordination from collection to re-infusion. The entire process is time-sensitive, often taking several weeks, which can be problematic for patients with aggressive diseases [8] [11]. Furthermore, the quality and potency of autologous cells can be highly variable due to factors such as the patient's age, underlying disease, and prior treatments, potentially affecting therapeutic efficacy [8]. Despite these challenges, the autologous cell therapy market is experiencing significant growth, with projections indicating expansion from US$11.41 billion in 2025 to US$54.21 billion by 2034, driven by advances in regenerative medicine and increasing adoption of personalized healthcare [25].

This application note provides a detailed technical protocol for the autologous cell therapy process, from initial leukapheresis through final re-infusion, with particular emphasis on optimization strategies for cell expansion and activation.

Technical Protocol: The Autologous Workflow

The autologous cell therapy manufacturing process comprises multiple interconnected stages, each requiring precise execution and quality control. The following workflow outlines the critical path from patient mobilization to product administration.

Patient Mobilization and Leukapheresis

The initial phase focuses on mobilizing hematopoietic stem cells from the bone marrow into the peripheral blood, followed by collection via leukapheresis.

Mobilization Strategies:

- Granulocyte Colony-Stimulating Factor (G-CSF): Administration of filgrastim (G-CSF) at 5-10 μg/kg/day for 4-5 days is the standard protocol for mobilizing CD34+ cells into peripheral blood [26]. This approach is typically well-tolerated, with side effects including bone pain, headache, and low-grade fever that rarely interfere with collection [26].

- Chemotherapy plus G-CSF: For patients with certain malignancies, mobilization using cyclophosphamide-based chemotherapy followed by G-CSF administration may yield higher CD34+ cell counts, though this approach carries greater toxicity and requires careful monitoring [26].

Leukapheresis and CD34+ Monitoring: Leukapheresis is typically initiated when the peripheral blood CD34+ count reaches ≥10-20×10³/mL, which generally occurs 4-5 days after starting G-CSF mobilization or approximately 11 days following cyclophosphamide-based regimens [26]. The quantification of CD34+ progenitor cells by flow cytometry using the International Society of Hemotherapy and Graft Engineering (ISHAGE) protocol serves as a critical predictor of collection success [26]. Studies demonstrate a moderate positive correlation between peripheral blood CD34+ cell count and total CD34+ cell count/kg collected during apheresis (r=0.596; p<0.001), with every increase of 5 CD34+ cells/μL in peripheral blood predicting a mean increase of 0.38×10⁶ CD34+ cells/kg in the apheresis product [26].

Table 1: Key Parameters for Leukapheresis Monitoring and Collection

| Parameter | Target Value | Analytical Method | Clinical Significance |

|---|---|---|---|

| Peripheral Blood CD34+ Count | ≥10-20×10³/μL | Flow cytometry (ISHAGE protocol) | Predicts successful collection; minimum threshold for initiating apheresis [26] |

| Pre-apheresis White Blood Cell Count | 35,000-40,000/μL | Automated hematology analyzer | Indicates adequate mobilization response [26] |

| CD34+ Cell Percentage in PB | 0.03% (median) | Flow cytometry | Quality indicator of mobilization efficacy [26] |

| Minimum CD34+ Collection | 2-5×10⁶ cells/kg | Flow cytometry | Required for consistent engraftment [26] |

Cell Processing, Activation, and Expansion

Following collection, cells undergo processing, activation, and expansion to generate therapeutic quantities. For T-cell therapies like CAR-T, this represents the most technically complex phase.

Cell Processing and Selection:

- Peripheral Blood Mononuclear Cell (PBMC) Isolation: Density gradient centrifugation (Ficoll-Paque) separates mononuclear cells from other blood components.

- T-cell Selection: Negative or positive selection methods isolate T-cells using immunomagnetic techniques. Negative selection typically yields higher purity and preserves native functionality by avoiding antibody binding to critical surface receptors [27].

T-cell Activation and Expansion Protocol: The expansion protocol must balance achieving sufficient cell numbers while maintaining therapeutic potency and preventing terminal differentiation.

Table 2: Optimized T-cell Expansion Protocol Parameters

| Parameter | Optimal Condition | Alternative Options | Impact on Expansion |

|---|---|---|---|

| Initial Seeding Density | 1×10⁶ cells/mL | 0.5-2×10⁶ cells/mL | Higher densities can limit expansion potential [28] |

| Activation Method | ImmunoCult CD3/CD28/CD2 T-cell Activator at 25 μL/mL | CD3/CD28 beads alone | Triple activation enhances expansion (405±174-fold vs 240±90-fold) [28] |

| Cytokine Supplementation | 10 ng/mL IL-2 | IL-7, IL-15 for memory phenotypes | IL-2 supports robust expansion but may drive differentiation [28] |

| Day 3 Dilution | 8-fold volume increase | 4-16 fold increases | Critical optimization point; 8-fold increase maximizes expansion [28] |

| Subsequent Dilutions | 4-fold increases on days 5 & 7 | Variable based on cell density | Maintains cells at optimal density (1-2.5×10⁵ cells/mL) [28] |

| Total Expansion Period | 10-14 days | 7-21 days depending on application | Longer cultures risk differentiation and exhaustion [28] |

Detailed Expansion Methodology:

- Day 0 - Activation: Resuspend isolated T-cells at 1×10⁶ cells/mL in ImmunoCult-XF T Cell Expansion Medium supplemented with 10 ng/mL recombinant human IL-2. Add ImmunoCult Human CD3/CD28/CD2 T Cell Activator at 25 μL/mL [28].

- Day 3 - First Dilution: Increase total culture volume 8-fold with fresh medium containing IL-2. This critical step reduces cell density to approximately 1.25×10⁵ cells/mL, preventing contact-mediated inhibition and replenishing nutrients [28].

- Days 5 & 7 - Subsequent Dilutions: Perform 4-fold volume increases with fresh medium to maintain cells within the optimal density range of 1-2.5×10⁵ cells/mL [28].

- Days 10-14 - Harvest: When expansion plateaus (typically 800-fold expansion achievable), harvest cells for genetic modification or formulation. Monitor viability throughout, aiming for >85% [28].

This optimized protocol emphasizes the importance of early cell dilution, with day 3 identified as a critical intervention point for maximizing expansion potential. Research indicates that maintaining T-cells at lower densities during early expansion phases significantly improves both cell growth and viability, potentially by increasing nutrient availability per cell after activation signals have been received [28].

Genetic Modification (CAR Transduction)

For chimeric antigen receptor (CAR) T-cell therapies, genetic modification typically occurs following activation and prior to the main expansion phase.

Transduction Protocol:

- Timing: Transduce activated T-cells 24-48 hours post-activation, when cells are actively proliferating and most receptive to genetic modification.

- Viral Vector Application: Add lentiviral or retroviral vectors containing the CAR construct at appropriate multiplicity of infection (MOI), typically ranging from 1-10, depending on vector potency and cell type.

- Enhancement Strategies: Consider incorporating transduction enhancers such as retronectin or protamine sulfate to improve transduction efficiency.

- Expansion: Continue culture expansion post-transduction according to the established protocol, typically for 7-10 additional days to achieve therapeutic cell numbers.

The critical manufacturing challenge for autologous CAR-T therapies lies in maintaining consistent transduction efficiency and CAR expression across patient-specific batches with variable starting T-cell quality [8] [3].

Product Formulation, Cryopreservation, and Re-infusion

The final manufacturing stages focus on product formulation, quality control, and administration.

Formulation and Cryopreservation:

- Formulation: Wash and resuspend expanded cells in appropriate cryopreservation medium containing protein stabilizer (e.g., human serum albumin) and cryoprotectant (e.g., DMSO).

- Cryopreservation: Controlled-rate freezing followed by storage in vapor-phase liquid nitrogen ensures product stability during storage and transport.

Quality Control Testing: Each autologous product must undergo rigorous release testing including:

- Identity: Confirmation of cell type and CAR expression (if applicable)

- Potency: Cytotoxic activity against target cells

- Purity: Percentage of desired cell population

- Safety: Sterility, mycoplasma, endotoxin, and replication-competent virus testing

Patient Conditioning and Re-infusion:

- Lymphodepleting Chemotherapy: Patients typically receive conditioning chemotherapy (commonly fludarabine and cyclophosphamide) 2-7 days before infusion to enhance engraftment and persistence of therapeutic cells.

- Product Administration: Thaw cryopreserved product at bedside and administer via intravenous infusion according to established protocols, with appropriate premedication and monitoring for acute reactions.

The Scientist's Toolkit: Essential Reagents and Materials

Table 3: Key Research Reagent Solutions for Autologous Cell Therapy

| Reagent/Material | Function | Example Products | Application Notes |

|---|---|---|---|

| Cell Separation Media | Density gradient isolation of PBMCs | Ficoll-Paque Premium | Maintain sterile technique; process samples promptly after collection [27] |

| Immunomagnetic Cell Separation Kits | Negative or positive selection of target cells | EasySep Human T-cell Isolation Kit | Negative selection preserves native receptor function [27] |

| T-cell Activation Reagents | Polyclonal T-cell activation via CD3/CD28 signaling | ImmunoCult CD3/CD28/CD2 T Cell Activator | Triple activation enhances expansion compared to CD3/CD28 alone [28] |

| Cell Expansion Medium | Optimized nutrient formulation for T-cell growth | ImmunoCult-XF T Cell Expansion Medium | Xeno-free formulation suitable for clinical applications [28] |

| Recombinant Cytokines | Support T-cell proliferation and survival | Human Recombinant IL-2 | Concentration optimization critical (typically 10-100 IU/mL) [28] |

| Viral Vectors | Delivery of genetic material for modification | Lentiviral, retroviral vectors | Quality critical for consistent transduction efficiency [8] |

| Flow Cytometry Antibodies | Cell phenotyping and quantification | CD34, CD3, CD45, CD4, CD8 antibodies | ISHAGE protocol standard for CD34+ enumeration [26] |

Comparative Analysis: Autologous vs. Allogeneic Approaches

The autologous process described above differs fundamentally from allogeneic approaches in several key aspects that impact manufacturing strategy and clinical application.

Table 4: Autologous vs. Allogeneic Manufacturing Considerations

| Characteristic | Autologous Process | Allogeneic Process |

|---|---|---|

| Starting Material | Patient-derived cells (variable quality) | Healthy donor cells (consistent quality) [8] |

| Manufacturing Model | Patient-specific batch | Large-scale, off-the-shelf batches [8] [11] |

| Production Timeline | Several weeks | Immediate availability from cryostock [8] |

| Immune Compatibility | Perfect match; no rejection risk | Requires HLA matching or immunosuppression [8] |

| Manufacturing Cost | High per batch (service model) | Lower per dose (mass production model) [25] [11] |

| Scalability | Limited by patient-specific logistics | Highly scalable for broad distribution [8] [11] |

| Product Consistency | High variability between batches | Highly consistent across doses [11] |

| Regulatory Challenges | Complex chain of identity management | Standardized manufacturing controls [11] |

Technical Challenges and Innovative Solutions

The autologous cell therapy process faces several persistent challenges that drive ongoing research and development:

Manufacturing Efficiency: The high cost of autologous therapies (ranging from $300,000-$500,000 per patient) stems from complex, labor-intensive manufacturing processes [25]. Emerging solutions include:

- Automation and AI Integration: AI-powered systems are being implemented to optimize manufacturing, reduce costs, and improve scalability. Platforms utilizing predictive analytics, digital twins, and reinforcement learning algorithms enable adaptive manufacturing of CAR-T and iPSC-based autologous therapies [25].

- Process Intensification: Research focuses on shortening production timelines through rapid expansion protocols and reducing manual operations through closed automated systems [3].

Supply Chain Complexity: The patient-specific supply chain for autologous therapies introduces unique challenges in cold-chain maintenance, strict time constraints, and end-to-end traceability [3]. Innovative approaches include:

- Decentralized Manufacturing: Movement toward patient-adjacent, regionalized manufacturing facilities to reduce logistics complexity [3].

- Advanced Tracking Systems: Robust digital infrastructure to maintain chain-of-identity and chain-of-custody across the entire process [11].

Product Quality and Variability: The inherent variability of patient-derived starting material necessitates adaptive manufacturing approaches. Strategies include:

- Process Analytical Technologies: Implementation of real-time monitoring systems to adjust processes based on incoming cell quality [3].

- Alternative Cell Sources: Investigation of rejuvenation strategies for cells from heavily pretreated patients [8].

The autologous cell therapy process, from leukapheresis to re-infusion, represents a remarkable convergence of medical science and precision manufacturing. While technically demanding and resource-intensive, this patient-specific approach offers unparalleled immunological compatibility and has demonstrated transformative potential for conditions with limited treatment options. The continued refinement of activation protocols, expansion methodologies, and manufacturing technologies will be crucial for enhancing the efficiency, consistency, and accessibility of autologous therapies. As the field advances, integration of automation, artificial intelligence, and innovative supply chain solutions promises to address current limitations while maintaining the fundamental personalized nature of autologous treatment. The optimized protocols and technical insights provided in this application note serve as a foundation for researchers and clinicians working to advance this rapidly evolving field and bring the benefits of autologous cell therapy to broader patient populations.

Within the rapidly advancing field of regenerative medicine, the therapeutic paradigm is shifting from personalized, patient-specific (autologous) treatments toward scalable, donor-derived (allogeneic) "off-the-shelf" products [11]. This transition is fundamentally enabled by the creation of Master Cell Banks (MCBs)—highly characterized, uniform cell populations that serve as the perpetual starting material for producing thousands of therapeutic doses [4]. The establishment of robust MCBs is critical for ensuring the long-term consistency, safety, and commercial viability of allogeneic therapies, which are poised for significant market growth with a projected CAGR of 15.0% to 27.41% [29] [30].

Framed within a broader thesis comparing allogeneic and autologous expansion protocols, this document details the application notes and experimental protocols for generating and qualifying MCBs. The allogeneic approach offers a substantial manufacturing cost advantage, with estimated production costs of £930–1140 per dose compared to £2260–3040 for autologous therapies, largely due to standardized donor testing and batch release processes [4]. The following sections provide a detailed methodology for creating these foundational MCBs, a cornerstone for scaling up allogeneic cell therapies.

Application Notes: The Role and Importance of Master Cell Banks

Fundamental Principles of Master Cell Banks

An MCB is a collection of cells of uniform composition derived from a single tissue source, processed, cultured, and preserved under defined conditions. It serves as the primary source for all future production runs, ensuring a consistent and reproducible starting material for many years [4]. The key advantage of an MCB-based system is its ability to supply a virtually limitless number of doses for thousands of patients from a single, thoroughly qualified donor source [11] [8].

Strategic Advantages in Allogeneic Scale-Up

The use of an MCB system directly addresses several critical challenges in cell therapy manufacturing:

- Scalability and Cost-Effectiveness: Once established, an MCB enables the production of therapies on a commercial scale, dramatically reducing the per-dose cost of goods. This creates a more financially sustainable model compared to the complex, patient-specific "service-based" logistics of autologous therapies [11] [4].

- Product Consistency and Quality Control: By originating from a single, well-characterized donor, the MCB ensures unprecedented batch-to-batch consistency. This minimizes the product heterogeneity often encountered in autologous systems, where the patient's age, disease state, and prior treatments can compromise cell quality and potency [8] [4].

- Regulatory Path and "Off-the-Shelf" Availability: A fully qualified MCB is a key regulatory requirement. It underpins the "off-the-shelf" business model, allowing therapies to be produced, quality-tested, and made readily available for acute medical conditions, eliminating the weeks-long manufacturing wait associated with autologous treatments [11] [31].

Table 1: Quantitative Impact of Master Cell Bank Implementation on Manufacturing

| Manufacturing Aspect | Autologous Model (Per Patient) | Allogeneic Model (with MCB) |

|---|---|---|

| Donor Screening Cost (per dose) | £990–1320 [4] | £10–20 [4] |

| Release Testing Cost (per dose) | £300–500 (per batch of one) [4] | £3–5 (per batch of 100 doses) [4] |

| Total Manufacturing Cost (per dose) | £2260–3040 [4] | £930–1140 [4] |

| Product Availability | Weeks of turnaround time [11] [8] | Immediate, "off-the-shelf" [11] [8] |

| Batch Consistency | High variability between patients [8] | High consistency from a single source [4] |

Experimental Protocols

This protocol outlines the complete workflow for establishing a GMP-compliant Master Cell Bank, from donor selection to the cryopreservation of the MCB vials.

The following diagram illustrates the multi-stage workflow for creating a Master Cell Bank, from donor selection to the generation of a Working Cell Bank for production.

Diagram 1: Master Cell Bank Establishment Workflow.

Detailed Protocol Steps

Step 1: Donor Screening and Tissue Acquisition

- Objective: To identify a suitable healthy donor and acquire starting material free of adventitious agents and genetic abnormalities.

- Procedure:

- Donor Recruitment: Recruit a healthy donor following informed consent and ethical approval per ISSCR guidelines and local regulations [32].

- Comprehensive Donor Testing: Perform extensive screening on the donor. This includes:

- Infectious Disease Testing: Serological and molecular testing for HIV-1/2, HBV, HCV, HTLV, Syphilis, and other relevant pathogens.

- Genetic Screening: Karyotyping and genetic analysis to rule out predispositions to pertinent diseases (e.g., cancer) [4].

- Tissue Harvesting: Under aseptic conditions, collect the source tissue (e.g., peripheral blood, bone marrow, cord blood). For induced pluripotent stem cells (iPSCs), collect fibroblasts or peripheral blood mononuclear cells (PBMCs) as the starting material [31].

- Critical Reagents: Donor history questionnaire, sterile collection kits, pathogen test kits, cell culture medium.

Step 2: Cell Isolation, Reprogramming, and Expansion

- Objective: To establish a pure, undifferentiated, and expandable cell population from the donor tissue.

- Procedure:

- Cell Isolation: Isolate the target cell population using density gradient centrifugation (for MNCs) or enzymatic digestion (for tissues). For mesenchymal stem cells (MSCs), use plastic adherence selection [8].

- Reprogramming (for iPSC lines): If generating an iPSC-MCB, transfer the isolated somatic cells with non-integrating reprogramming vectors (e.g., Sendai virus, episomal plasmids) to create clonal induced pluripotent stem cell lines [31]. This step is bypassed for primary cell lines (e.g., primary MSCs).

- Clonal Selection & Expansion: Plate cells at clonal density. Manually pick and expand morphologically superior colonies to establish a clonal cell line. Culture and expand the cells over multiple passages in a GMP-compliant, xeno-free medium to achieve the target cell number for banking [33].

- Critical Reagents: GMP-grade enzymes (e.g., Collagenase), xeno-free cell culture media and growth factors, recombinant trypsin/EDTA, non-integrating reprogramming vectors.

Step 3: Master Cell Bank Creation and Cryopreservation

- Objective: To create a large inventory of characterized, cryopreserved cells at a low passage number.

- Procedure:

- Harvesting: When the culture reaches the desired cell density and population doublings, detach the cells using a gentle enzyme.

- Formulation: Wash and resuspend the cell pellet in a GMP-grade cryopreservation medium (e.g., containing 10% DMSO and a protein source like human serum albumin).

- Vialing & Controlled-Rate Freezing: Aseptically aliquot the cell suspension into several hundred cryovials (e.g., 1-5 x 10^6 cells/vial). Place the vials in a controlled-rate freezer, cooling at -1°C/min to -80°C to minimize ice crystal formation.

- Long-Term Storage: Transfer the vials to the vapor phase of a liquid nitrogen storage tank (-135°C to -196°C) for long-term preservation. Maintain a detailed inventory and chain-of-custody log.

- Critical Reagents: GMP-grade cryoprotectant (e.g., DMSO), formulation buffer, controlled-rate freezer, validated liquid nitrogen storage system.

Step 4: Quality Control and Characterization of the MCB

- Objective: To ensure the MCB's safety, identity, purity, and potency before its use in production.

- Procedure: Perform the following tests on representative vials thawed from the MCB.

Table 2: Master Cell Bank Quality Control Tests and Specifications

| Test Category | Specific Assay | Acceptance Criteria |

|---|---|---|

| Safety | Sterility (USP <71>) | No microbial growth [33] |

| Mycoplasma (e.g., PCR) | Negative | |

| Endotoxin (LAL) | < 0.5 EU/mL | |

| In vitro Adventitious Virus Assay | Negative | |

| Identity | Short Tandem Repeat (STR) Profiling | Matches donor sample [33] |

| Flow Cytometry for Cell Surface Markers | ≥ 95% positive for expected markers (e.g., CD73, CD90, CD105 for MSCs; Tra-1-60, SSEA-4 for iPSCs) [8] | |

| Purity | Viability (e.g., Trypan Blue Exclusion) | ≥ 90% post-thaw |

| Flow Cytometry for Contaminating Markers | ≤ 2% positive for lineage-specific markers not expected | |

| Potency | In vitro Differentiation Assay (e.g., to osteo-, adipo-, chondro-lineages) | Demonstration of multi-lineage potential [33] |

| Functional Assay (e.g., immunomodulation) | Meets established product-specific benchmarks | |

| Genetic Stability | Karyotyping (G-banding) | Normal diploid karyotype |

| Copy Number Variant (CNV) Analysis | No major aberrations |

Step 5: Working Cell Bank (WCB) Generation

- Objective: To create an intermediate bank from the MCB to supply the manufacturing process without exhausting the master bank.

- Procedure: Thaw one vial of the qualified MCB. Expand the cells for a limited number of population doublings (typically 2-4 passages) under the same conditions used for the MCB. Harvest, cryopreserve, and quality-control the WCB vials using a subset of the tests performed on the MCB (e.g., viability, sterility, mycoplasma, identity). A single WCB is used to generate one batch of the final product [4].

The Scientist's Toolkit: Essential Reagent Solutions

The following table lists key reagents and materials critical for the successful execution of the MCB establishment protocol.