GMP for Scalable Stem Cell Biomanufacturing: A Guide to Compliance, Automation, and Clinical Translation

This article provides a comprehensive guide for researchers, scientists, and drug development professionals on implementing Good Manufacturing Practice (GMP) for scalable stem cell biomanufacturing.

GMP for Scalable Stem Cell Biomanufacturing: A Guide to Compliance, Automation, and Clinical Translation

Abstract

This article provides a comprehensive guide for researchers, scientists, and drug development professionals on implementing Good Manufacturing Practice (GMP) for scalable stem cell biomanufacturing. Covering foundational regulations from the FDA and EMA, it delves into advanced automated platforms like the Quantum® system and CliniMACS Prodigy® for large-scale production. The content addresses critical troubleshooting aspects, including managing knowledge transfer and reducing operational costs, and outlines validation strategies for analytical methods and navigating diverse global regulatory pathways. The synthesis of these elements offers a strategic roadmap for transitioning stem cell therapies from research to robust, compliant, and commercially viable clinical applications.

GMP Fundamentals and Regulatory Frameworks for Stem Cell Therapies

Current Good Manufacturing Practice (CGMP) regulations form the foundation for ensuring pharmaceutical product quality and safety. Established and enforced by the U.S. Food and Drug Administration (FDA), these regulations provide minimum requirements for the methods, facilities, and controls used in manufacturing, processing, and packing of drug products [1] [2]. The fundamental objective is to ensure that drug products have the identity, strength, quality, and purity they claim to possess, ultimately protecting patient safety [3].

The "C" in CGMP stands for "current," requiring manufacturers to employ up-to-date technologies and systems that evolve with modern standards [2]. This dynamic nature distinguishes CGMP from static GMP standards, emphasizing continuous improvement and adoption of advanced manufacturing technologies to achieve higher quality through ongoing enhancement of processes and controls [3] [4]. For stem cell biomanufacturing researchers, understanding these requirements is crucial for developing scalable processes that meet regulatory expectations while maintaining product consistency and quality.

Regulatory Framework and Key Sections

The CGMP regulations are codified in Title 21 of the Code of Federal Regulations (CFR), which interprets the Federal Food, Drug and Cosmetic Act [1]. The pharmaceutical quality-related regulations appear in several parts of Title 21, with specific sections governing different aspects of pharmaceutical manufacturing:

Table: Key CGMP Regulations for Pharmaceutical Products

| CFR Section | Regulatory Focus | Application in Biomanufacturing |

|---|---|---|

| 21 CFR Part 210 | Current Good Manufacturing Practice in Manufacturing, Processing, Packing, or Holding of Drugs | General framework for all drug manufacturing operations |

| 21 CFR Part 211 | Current Good Manufacturing Practice for Finished Pharmaceuticals | Specific requirements for final drug products |

| 21 CFR Part 212 | Current Good Manufacturing Practice for Positron Emission Tomography Drugs | Specialized requirements for radiopharmaceuticals |

| 21 CFR Part 600 | Biological Products: General | Regulations specific to biological products |

| 21 CFR Part 1271 | Human Cells, Tissues, and Cellular and Tissue-Based Products | Directly applicable to stem cell-based products |

For stem cell biomanufacturing, multiple regulatory sections often apply concurrently. While 21 CFR Part 211 establishes requirements for finished pharmaceuticals, Part 1271 provides specific governance for cellular products, creating a comprehensive regulatory framework that researchers must navigate during process development [5].

Core CGMP Requirements: Detailed Analysis

Quality Management Systems

A robust quality management system (QMS) forms the cornerstone of CGMP compliance. The regulations mandate establishing a quality control unit with defined responsibilities and authority to approve or reject all components, drug product containers, closures, in-process materials, packaging materials, labeling, and drug products [5]. This unit must maintain adequate laboratory facilities for testing and approval (or rejection) of materials and products, with all responsibilities and procedures documented in writing [5].

For stem cell biomanufacturing, the QMS must incorporate:

- Quality by Design (QbD): Systematic approach to development that emphasizes product and process understanding based on sound science and quality risk management [6]

- Quality Risk Management: Proactive identification and mitigation of risks throughout the product lifecycle

- Corrective and Preventive Action (CAPA): Processes for investigating and correcting discrepancies while preventing recurrence [3]

- Change Control Management: Formal assessment and documentation of process changes [6]

Facility and Environmental Controls

CGMP regulations specify detailed requirements for manufacturing facilities to prevent contamination and ensure product consistency [5]. For stem cell biomanufacturing, these requirements present unique challenges due to the sensitive nature of living cells.

Table: Facility Requirements for Advanced Therapies

| Facility Element | CGMP Requirement | Stem Cell Application |

|---|---|---|

| Design & Construction | Suitable size, construction and location to facilitate cleaning, maintenance, and proper operations [5] | Segregated areas for different process steps with appropriate environmental controls |

| Air Quality Systems | Adequate ventilation with controls for air pressure, microorganisms, dust, humidity, and temperature [5] | HEPA filtration with appropriate classification for aseptic processing |

| Process Areas | Separate or defined areas to prevent contamination or mixups [5] | Dedicated gowning areas, material airlocks, and classified processing environments |

| Utilities | Potable water meeting EPA standards; proper drainage systems [5] | Water-for-injection systems for critical process steps |

| Sanitation Program | Written procedures for cleaning schedules, methods, equipment, and materials [5] | Validated cleaning procedures with appropriate detergents and sanitizers |

The FDA's guidance emphasizes that facilities must maintain controlled environmental conditions to prevent cross-contamination from adulterants and allergens that may render the product unsafe [7]. For stem cell products, this extends to controlling viable and non-viable particulates, temperature, humidity, and air pressure differentials between process areas.

Equipment Design and Maintenance

Equipment used in manufacturing must be adequately designed, constructed, cleaned, maintained, and calibrated [5]. The January 2025 FDA draft guidance on CGMP further clarifies that equipment adjustments may be made without additional quality unit approval if within preestablished, scientifically justified limits that have been previously approved [8]. This flexibility is particularly relevant for advanced manufacturing technologies where real-time process adjustments may be necessary.

For stem cell biomanufacturing, equipment considerations include:

- Material Compatibility: Equipment surfaces contacting cells or reagents must be non-reactive, non-additive, and non-absorptive [3]

- Calibration Program: Regular calibration according to established schedules and procedures [6]

- Preventive Maintenance: Scheduled maintenance to prevent equipment failure [3]

- Cleaning Validation: Evidence that cleaning procedures effectively remove product and cleaning agent residues [5]

Personnel Qualifications and Training

CGMP regulations emphasize that personnel engaged in manufacturing must have appropriate education, training, and experience to perform their assigned functions [5]. Training must be conducted by qualified individuals on a continuing basis with sufficient frequency to ensure employees remain familiar with CGMP requirements applicable to them [5].

Stem cell biomanufacturing facilities must ensure:

- Technical Competency: Personnel have specific training in aseptic techniques and cell culture methods

- CGMP Training: Regular training on current good manufacturing practice regulations [3]

- Aseptic Technique Qualification: Demonstration of proficiency in aseptic operations

- Health and Hygiene: Practices to prevent product contamination from personnel [5]

Advanced Manufacturing Technologies and CGMP

The FDA's recent draft guidance from January 2025 addresses considerations specific to advanced manufacturing technologies, which include innovative approaches relevant to stem cell biomanufacturing [8]. Advanced manufacturing is defined as a new or innovative manufacturing technology that enhances drug quality, scales up production, and reduces time-to-market [8].

Process Models and Real-Time Monitoring

The draft guidance acknowledges the industry's interest in using process models to monitor in-process materials affecting critical quality attributes and predict uniformity and homogeneity [8]. However, FDA advises against using process models alone and recommends pairing them with in-process material testing or process monitoring to ensure compliance with 21 CFR § 211.110 [8].

For stem cell biomanufacturing, this translates to:

- Process Analytical Technology (PAT): Real-time monitoring of critical process parameters

- Multivariate Analysis: Statistical models correlating process parameters with product quality attributes

- Real-time Release Testing: Ability to evaluate quality attributes during processing rather than through finished product testing alone

Continuous Manufacturing Considerations

The integrated nature of continuous manufacturing presents unique challenges for sampling and testing [8]. FDA recognizes that physical isolation and removal of samples may be less feasible in continuous processes compared to traditional batch manufacturing [8]. The guidance allows for alternative approaches where manufacturers could conduct sampling and testing at appropriate points in the process, with quality unit approval or rejection of in-process material before or after such points [8].

Experimental Protocols for CGMP Compliance

Environmental Monitoring Protocol

Objective: To establish and maintain controlled environmental conditions suitable for aseptic stem cell manufacturing.

Methodology:

- Classification of Cleanrooms: Establish ISO-classified environments based on intended operations (e.g., ISO 5 for critical operations)

- Particulate Monitoring: Continuous monitoring of non-viable particulates in critical areas

- Microbial Monitoring: Routine collection of viable air and surface samples using settle plates, contact plates, and active air samplers

- Personnel Monitoring: Assessment of gowning effectiveness through finger plates and gown contact plates

- Data Analysis: Trend monitoring data and establish alert and action limits

Acceptance Criteria: Environments must maintain classification according to ISO 14644 with no adverse trends in microbial recovery.

Process Validation Protocol

Objective: To establish documented evidence providing high degree of assurance that a specific process consistently produces a product meeting its predetermined specifications and quality attributes.

Methodology:

- Stage 1 - Process Design: Define target product profile, identify critical quality attributes, and establish process parameters

- Stage 2 - Process Qualification: Design facility and equipment qualification followed by process performance qualification

- Stage 3 - Continued Process Verification: Ongoing monitoring to ensure process remains in state of control

Stem Cell Application:

- Focus on critical process parameters affecting cell viability, identity, potency, and purity

- Define in-process controls and testing strategies

- Establish process ranges rather than fixed setpoints where appropriate

In-Process Control Strategy

Following 21 CFR § 211.110, manufacturers must conduct in-process controls, tests, or examinations to prevent contamination and monitor quality attributes of in-process materials [8]. The FDA recommends a scientific and risk-based approach outlining what, where, when, and how in-process controls should be conducted [8].

Implementation Framework:

- Risk Assessment: Identify potential failure modes and their impact on product quality

- Control Point Identification: Determine optimal points in the process for monitoring and control

- Method Selection: Choose appropriate analytical methods capable of detecting variations

- Sampling Plan: Establish statistically justified sampling plans

- Data Management: Implement systems for data collection, analysis, and trend monitoring

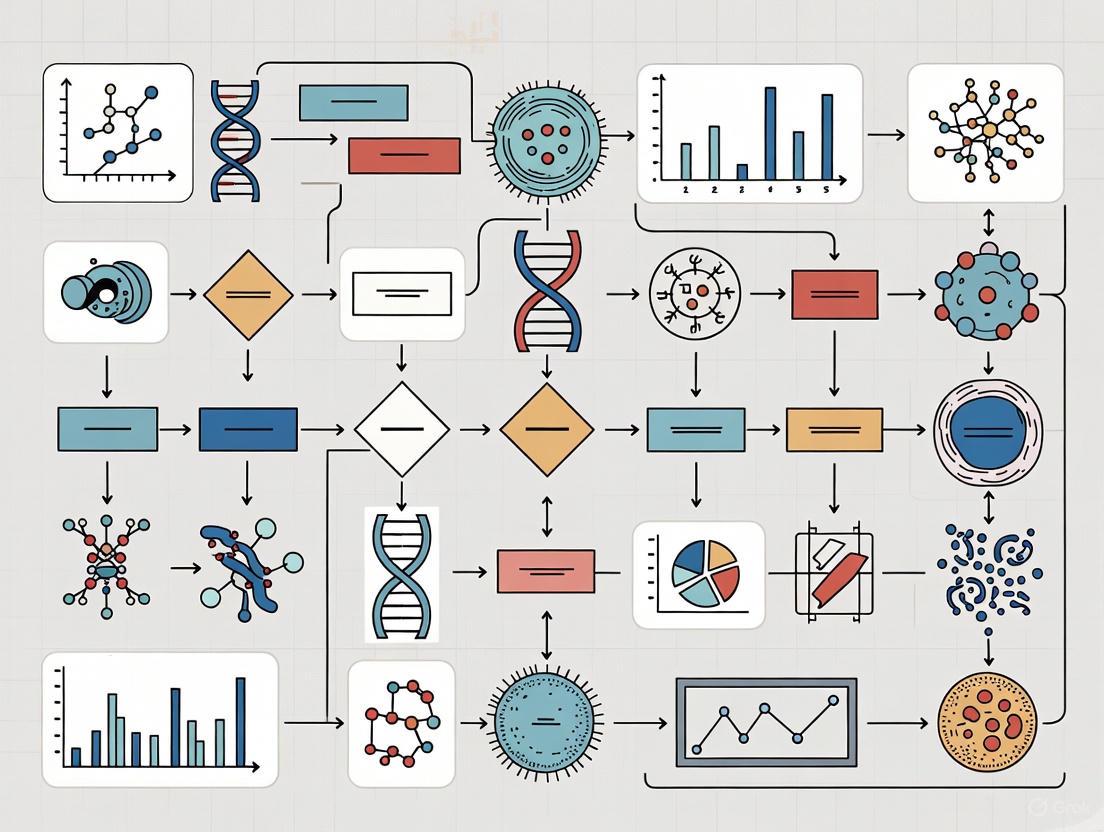

Visualization of CGMP Compliance Framework

CGMP Compliance Framework Diagram

The Scientist's Toolkit: Essential Research Reagents and Materials

Table: Critical Materials for Stem Cell Biomanufacturing

| Material/Reagent | Function | CGMP Considerations |

|---|---|---|

| Cell Culture Media | Supports cell growth and maintenance | Qualified components, endotoxin testing, batch-to-batch consistency |

| Growth Factors/Cytokines | Directs cell differentiation and proliferation | Purity documentation, activity verification, supplier qualification |

| Extracellular Matrix Components | Provides structural support for cell attachment | Bioburden control, identity testing, freedom from adventitious agents |

| Dissociation Reagents | Enzymatic or non-enzymatic cell detachment | Purity, specificity, removal validation during process |

| Critical Process Materials | Contact product during manufacturing (filters, tubing, containers) | Extractables and leachables testing, biocompatibility, supplier qualification |

| Cell Sorting Reagents | Isolation of specific cell populations | Purity, specificity, validation of removal if required |

| Cryopreservation Solutions | Long-term storage of cell products | Formulation consistency, sterility, container compatibility |

Implementing CGMP requirements in stem cell biomanufacturing research requires a systematic approach that integrates quality principles from initial process development through scale-up and technology transfer. The flexibility inherent in CGMP regulations allows manufacturers to implement innovative approaches while maintaining compliance, provided they can scientifically justify their methods and demonstrate control [2].

As emphasized in the recent FDA draft guidance, manufacturers should adopt a risk-based approach to in-process controls, leveraging advanced manufacturing technologies where appropriate while maintaining traditional quality systems [8]. For stem cell researchers transitioning from bench to commercial scale, early adoption of CGMP principles facilitates smoother scale-up and regulatory approval, ultimately accelerating the delivery of transformative therapies to patients.

For researchers and scientists pioneering scalable stem cell biomanufacturing, navigating the regulatory landscape is as crucial as the science itself. The U.S. Food and Drug Administration (FDA) establishes current good manufacturing practice (CGMP) requirements to ensure that drugs, including Advanced Therapy Medicinal Products (ATMPs), are consistently produced and controlled to quality standards appropriate for their intended use [9]. These regulations are codified primarily in 21 CFR Parts 210 and 211, which form the foundational regulatory framework for pharmaceutical manufacturing in the United States [10] [5]. For stem cell-based therapies, which are often classified as ATMPs, compliance with these regulations presents unique challenges due to the complex, living nature of the products and the need for aseptic processing throughout manufacturing [11]. This application note provides a detailed analysis of these key regulations within the context of scalable stem cell biomanufacturing research, offering practical guidance and protocols to facilitate regulatory compliance while advancing therapeutic development.

Regulatory Breakdown: 21 CFR Parts 210 & 211

Core Definitions and Interrelationship

21 CFR Part 210, "Current Good Manufacturing Practice in Manufacturing, Processing, Packing, or Holding of Drugs; General," establishes the overarching scope and status of CGMP regulations [10]. It specifies that compliance with these parts constitutes the minimum requirements to assure a drug's safety, identity, strength, quality, and purity [10] [12]. 21 CFR Part 211, "Current Good Manufacturing Practice for Finished Pharmaceuticals," provides the detailed, actionable requirements for implementing these quality standards across all aspects of production [5] [12]. Together, they form a cohesive system where Part 210 defines the "what" and Part 211 prescribes the "how" of drug manufacturing quality [12].

Table 1: Core Scope and Definitions in 21 CFR Part 210 [10] [12]

| Concept | Regulatory Citation | Definition & Significance for Stem Cell Biomanufacturing |

|---|---|---|

| Status of CGMP | §210.1 | Establishes that Parts 210, 211, 225, and 226 contain the minimum CGMP requirements. Non-compliance renders a drug "adulterated." |

| Applicability | §210.2 | Regulations supplement, do not supersede each other. Phase 1 investigational drugs are exempt from Part 211, but this exemption ceases for Phase 2/3 studies. |

| Batch | §210.3(b)(2) | A specific quantity of material intended to be uniform, produced in a single cycle. Critical for defining product lot size and consistency in cell culture. |

| Component | §210.3(b)(3) | Any ingredient used in drug product manufacture. For cell therapies, this includes culture media, growth factors, and cytokines. |

| Quality Control Unit | §210.3(b)(15) | Any person or element designated for quality control duties. Must be independent and have authority to approve/reject materials and products. |

| Representative Sample | §210.3(b)(21) | A sample drawn based on rational criteria to accurately portray the material being sampled. Essential for reliable in-process and final product testing. |

Key Operational Requirements under 21 CFR Part 211

Part 211 provides comprehensive, subpart-specific controls that are critical for establishing a robust manufacturing process for stem cell-based ATMPs.

Organization and Personnel (§211.22-§211.34): Requires a distinct, authoritative quality control unit with responsibility for approving/rejecting all components, containers, closures, in-process materials, and drug products [5]. Personnel must have adequate education, training, and experience, and must adhere to strict hygiene and sanitation practices to prevent product contamination [5] [9].

Buildings and Facilities (§211.42-§211.58): Mandates that facilities be of suitable design to facilitate cleaning, maintenance, and proper operations, with separate or defined areas to prevent contamination and mix-ups [5]. This is particularly critical for aseptic processing of ATMPs, requiring features like HEPA-filtered air under positive pressure and environmental monitoring systems [5] [11].

Production and Process Controls (§211.100-§211.115): Requires written procedures for production and process control, designed to ensure products have the identity, strength, quality, and purity they purport to possess [5]. This includes the critical concept of process validation, confirming that a process consistently produces a result meeting its pre-determined specifications [13].

Table 2: Selected Key Requirements of 21 CFR Part 211 for ATMP Biomanufacturing [5]

| Subpart | Section | Key Focus | Implication for Stem Cell ATMPs |

|---|---|---|---|

| B: Organization & Personnel | 211.22 | Quality Control Unit | Independent oversight and final authority on quality decisions for cell batches. |

| C: Buildings & Facilities | 211.42 | Design & Construction | Defined areas for each operation (e.g., cell processing, packaging) to prevent cross-contamination. |

| D: Equipment | 211.63 | Design & Size | Equipment must be of appropriate design and size for intended use (e.g., bioreactors). |

| E: Component Control | 211.84 | Testing & Approval | Rigorous testing and acceptance of raw materials like cytokines, media, and sera. |

| F: Production & Control | 211.100 | Written Procedures | Strict adherence to and documentation of Standard Operating Procedures (SOPs) for all processes. |

| I: Laboratory Controls | 211.165 | Testing & Release | Establishing scientifically sound specifications and testing for safety, purity, and potency of final cell product. |

| J: Records & Reports | 211.188 | Batch Production Record | Complete and accurate documentation of the production history of each batch of a drug product. |

ATMPs: Classification and Manufacturing Challenges

ATMP Classification and Regulatory Context

Advanced Therapy Medicinal Products (ATMPs) represent a groundbreaking category of medications that utilize biological-based products to treat or replace damaged tissues and organs [11]. Within the regulatory framework, ATMPs are broadly classified into several categories, which can be aligned with specific FDA regulatory pathways. It is important to note that the term "ATMP" itself is derived from European Union/United Kingdom regulatory frameworks, but the FDA regulates analogous products under specific categories for cells, tissues, and gene therapies [11].

Table 3: ATMP Classifications and Corresponding U.S. Regulatory Considerations

| ATMP Category | Core Definition | Examples Relevant to Stem Cells | Key U.S. Regulatory Consideration |

|---|---|---|---|

| Somatic Cell Therapy Medicinal Products (sCTMPs) | Uses autologous or allogeneic cells manipulated ex vivo to change their biological characteristics. | Expanded mesenchymal stem/stromal cells (MSCs), differentiated cardiomyocytes. | Regulated as biologic products under 21 CFR 1271 (HCT/Ps) and 21 CFR 210/211. Often requires BLA. |

| Tissue-Engineered Products (TEPs) | Contains or consists of engineered cells or tissues to repair, regenerate, or replace human tissue. | Stem cell-seeded scaffolds for bone or cartilage repair. | Combination product regulation (device + biologic). CGMP compliance for both components (e.g., 21 CFR 211 & 820). |

| Combined ATMPs | An ATMP that incorporates one or more medical devices as an integral part of the product. | Cell therapy product combined with a biodegradable matrix or delivery device. |

Critical Manufacturing Hurdles in Scalable Stem Cell Biomanufacturing

Transitioning stem cell research from a laboratory discovery to a commercially viable, regulated therapeutic product involves overcoming significant manufacturing challenges under the CGMP framework.

Transitioning from GLP to GMP: A primary barrier is implementing GMP-compliant manufacturing processes that reliably meet the quality specifications defined during product development, including data from Good Laboratory Practice (GLP)-compliant non-clinical studies [11]. While GLP focuses on protecting the integrity of non-clinical safety and efficacy data, GMP is concerned with protecting the final product from contamination and ensuring it consistently meets pre-defined quality standards [11]. This transition requires securing a reliable supply of GMP-grade raw materials, developing standardized cell characterization assays, and implementing robust quality control systems [11].

Safety and Contamination Control: Stem cell products must be free of contamination, but traditional sterilization methods are not feasible as they would compromise cell viability [11]. Consequently, manufacturing must occur under validated aseptic conditions, often requiring closed, automated systems and rigorous environmental monitoring to reduce risk [11]. A paramount safety concern is tumorigenesis, or the potential for stem cells to form tumors, which must be assessed using sensitive in vitro methods and in vivo studies in immunocompromised models [11].

Scalability and Process Validation: Scaling up cell culture from laboratory to clinical and commercial volumes is a multifaceted challenge. The most critical concern is demonstrating product comparability after any manufacturing process change [11]. Regulators require a risk-based comparability assessment, extensive analytical characterization, and staged testing to ensure changes do not impact the safety or efficacy of the final cell product [11]. This often involves moving from planar culture vessels to GMP-compliant bioreactors and developing comprehensive process validation protocols [11].

Practical Application: Protocols for Compliance and Process Validation

Experimental Protocol: Validation of Aseptic Processing (Media Fill)

A "media fill" or process simulation test is a critical validation study that demonstrates the capability of the aseptic manufacturing process to produce a sterile product [11].

1. Objective: To validate the aseptic manufacturing process for a stem cell-based ATMP by simulating all manual aseptic operations using a sterile growth medium, thereby providing sterility assurance.

2. Scope: This protocol applies to the final formulation and filling steps of the ATMP manufacturing process.

3. Materials and Equipment:

- Tryptic Soy Broth (TSB) or other suitable sterile culture media.

- Identical container-closure system used for the final drug product.

- Production-grade biosafety cabinet or isolator.

- All standard production equipment (e.g., tubing, pumps, filters).

- Incubators set at 20-25°C and 30-35°C.

4. Methodology: 1. Preparation: Prepare and sterilize the culture media according to standard procedures. Ensure the processing area is at the operational qualification state and has been cleaned and sanitized per approved SOPs. 2. Simulation Execution: A qualified operator shall perform all routine aseptic manipulations (e.g., connections, transfers, additions) using the sterile media instead of the cell product. The simulation should include the maximum number of interventions and the longest expected run time for a single batch. 3. Filling: Aseptically fill the specified number of units with the sterile media. The number of units filled should be sufficient to detect a potential contamination rate with 95% confidence. 4. Incubation and Observation: Incubate 100% of the filled units at 20-25°C for 7 days, followed by incubation at 30-35°C for 7 days. Observe all units for microbial growth (turbidity) at the end of each incubation period. 5. Positive Control: Inoculate a separate unit of the media with a low level (fewer than 100 CFU) of a suitable microorganism (e.g., Staphylococcus aureus, Bacillus subtilis) to confirm the media's ability to support growth.

5. Acceptance Criteria: The media fill is considered to have passed only if 0 out of the statistically determined number of units (frequently set at a minimum of 4,750-5,000 units for commercial processes) show evidence of microbial growth. Any positive unit constitutes a failure and triggers a thorough investigation and re-validation.

Experimental Protocol: In Vitro Tumorigenicity Assay (Digital Soft Agar)

For pluripotent stem cell (PSC)-derived products, testing for residual undifferentiated cells with tumorigenic potential is a critical safety release criterion [11]. This protocol describes a sensitive digital soft agar method.

1. Objective: To detect and quantify rare transformed cells in a stem cell-based therapeutic product by assessing anchorage-independent growth in a semi-solid medium, a hallmark of neoplastic transformation.

2. Scope: This assay is suitable for final cell products and in-process samples, particularly those derived from PSCs.

3. Materials and Equipment:

- Base Agar (e.g., 1.2% Noble Agar in basal medium).

- Top Agar (e.g., 0.7% Noble Agar in complete growth medium).

- Appropriate positive control cells (e.g., HeLa or other transformed cell line).

- Negative control cells (e.g., primary human fibroblasts).

- 6-well or 12-well cell culture plates.

- Automated cell counter or flow cytometer.

- High-resolution digital scanner or imager.

4. Methodology: 1. Agar Base Layer Preparation: Melt the base agar and maintain at 40-45°C in a water bath. Add a 1-2 mL layer to each well of the culture plate and allow it to solidify at room temperature. 2. Cell Seeding in Top Agar: Trypsinize, count, and resuspend the test article cells and controls. Mix the cell suspension with liquefied top agar (maintained at 37°C) to achieve a final density of 1x10^4 to 5x10^4 cells/mL. Quickly layer 1-2 mL of this cell-top agar mixture over the base layer in each well. Perform this step in triplicate for each sample. 3. Incubation and Feeding: Allow the top agar to solidify, then add a thin layer (0.5-1 mL) of complete growth medium on top to prevent drying. Incubate the plates at 37°C, 5% CO2 for 3-4 weeks, replenishing the top medium weekly. 4. Image Acquisition and Analysis: At the endpoint, digitally scan each well at high resolution. Use image analysis software to automatically identify and count cell colonies larger than a pre-defined threshold (e.g., 50 μm in diameter).

5. Acceptance Criteria: The test article is considered acceptable if the number of colonies formed per 10,000 cells plated is statistically indistinguishable from the negative control and falls below a pre-defined, risk-based specification limit. The positive control must demonstrate robust colony formation for the assay to be valid.

The Scientist's Toolkit: Essential Research Reagent Solutions

The transition from research to GMP-compliant manufacturing necessitates the use of qualified reagents and materials. The following table details key solutions essential for stem cell biomanufacturing research and process development.

Table 4: Key Research Reagent Solutions for Stem Cell Biomanufacturing

| Reagent/Material | Function | GMP-Compliance Consideration |

|---|---|---|

| GMP-Grade Human Serum or Xeno-Free Media Supplements | Provides essential nutrients, growth factors, and hormones for cell growth and maintenance. | Must be sourced from qualified vendors, with certificates of analysis (CoA) and full traceability to ensure absence of adventitious agents. |

| Recombinant Human Growth Factors (e.g., FGF-2, TGF-β) | Directs stem cell proliferation, maintenance of pluripotency, or guides specific differentiation pathways. | Requires GMP-manufactured, animal-origin-free cytokines with documented purity, potency, and stability. |

| Cell Dissociation Enzymes | Passaging and harvesting adherent stem cells from culture surfaces. | Non-animal derived, recombinant enzymes (e.g., recombinant trypsin) are preferred to reduce contamination risk and lot-to-lot variability. |

| Closed-System Bioprocess Containers | Single-use bags and assemblies for media preparation, cell culture, and storage. | Pre-sterilized, USP Class VI certified, and extractables/leachables tested to ensure product compatibility and safety. |

| Annexin V / Viability Assay Kits | Quantifying apoptosis and cell viability for in-process controls and product potency assays. | Assays must be validated for accuracy, precision, and robustness according to ICH guidelines when used for lot release. |

Workflow and Process Diagrams

GMP Transition Workflow for ATMP Development

The following diagram illustrates the logical progression of a stem cell therapy from research to a GMP-compliant clinical product, highlighting key regulatory and development milestones.

Core GMP Control Systems Interrelationship

This diagram depicts the logical relationships between the core control systems required by 21 CFR Part 211 and how they interact to ensure overall product quality.

Successfully navigating the regulatory landscape of 21 CFR Parts 210 and 211 is a fundamental requirement for translating innovative stem cell research into viable, commercially available ATMPs. This journey from a GLP research environment to a GMP-compliant manufacturing operation is complex, requiring meticulous planning, robust process validation, and an unwavering commitment to quality [11]. By understanding the definitions and scope of Part 210, implementing the detailed controls of Part 211, and proactively addressing the unique challenges of ATMP manufacturing—such as aseptic processing, tumorigenicity risk, and scalability—research organizations can build a solid foundation for regulatory success. Embracing these principles not only facilitates compliance but also instills a culture of quality that is essential for developing safe and effective stem cell therapies for patients.

For researchers and scientists engaged in scalable stem cell biomanufacturing, navigating the global regulatory landscape is a critical component of translational success. Current Good Manufacturing Practices (GMP) form the foundation of this landscape, but their interpretation and implementation vary significantly across the European Union (EU), the United States (US), and key Asian markets. Recent and forthcoming regulatory updates, particularly in the EU concerning computerized systems and artificial intelligence, are dramatically reshaping compliance requirements. This application note provides a comparative analysis of these regions, structured tables of quantitative data, detailed experimental protocols for regulatory adherence, and essential workflow visualizations. The aim is to equip drug development professionals with the knowledge and methodologies necessary to align their research and production processes with the most current international standards, thereby facilitating smoother transition from laboratory discovery to clinical application.

The transition from research-scale stem cell culture to GMP-compliant biomanufacturing introduces a complex array of regulatory challenges. The core principle of GMP is to ensure that products are consistently produced and controlled according to quality standards appropriate to their intended use [14]. For stem cell therapies, this involves rigorous control over every aspect of the process, from sourcing of raw materials and characterization of cell lines to the validation of manufacturing processes and quality control testing.

Scalable biomanufacturing presents unique hurdles, such as the adaptation of research protocols to closed, automated systems, the maintenance of cell potency and genetic stability during expansion, and the implementation of real-time quality monitoring. Facilities like the Cedars-Sinai Biomanufacturing Center exemplify the physical and quality system infrastructure required, featuring multiple ISO Class 7 cleanroom suites and dedicated areas for process development to support clinical trials [15]. Similarly, Waisman Biomanufacturing highlights capabilities crucial for the field, including the creation of GMP human embryonic and induced pluripotent stem cell banks, and the development of processes for the expansion and differentiation of these cells [16]. Understanding the regulatory frameworks that govern these operations is the first step in building a compliant and successful biomanufacturing program.

Comparative Analysis of Regional GMP Frameworks

The regulatory philosophies in the EU, US, and Asia, while all founded on the principle of quality and patient safety, differ in their specific requirements, emphasis, and operational details. A comparative analysis reveals distinct regional profiles.

European Union (EU) Regulatory Framework

The EU's regulatory framework, EudraLex Volume 4, is undergoing its most significant transformation in over a decade, with pivotal draft updates released for consultation in July 2025 [17] [18].

- Key Guidelines: The core GMP requirements are detailed in EudraLex Volume 4. The draft Annex 11 (Computerised Systems) has been expanded from 5 to 19 pages, reflecting the modern, digital, and cloud-integrated pharmaceutical environment [17]. Simultaneously, a draft Chapter 4 (Documentation) introduces a stronger focus on the data lifecycle, metadata control, and the management of hybrid systems (paper and electronic) under the Pharmaceutical Quality System (PQS) [18]. A entirely new Annex 22 (Artificial Intelligence) is also proposed, addressing the use of static AI/ML models in GMP environments [17] [18].

- Recent Updates (2025): The draft Annex 11 places a clear emphasis on cybersecurity controls, mandating regular penetration testing for high-risk systems and explicit management responsibility for IT system oversight [17]. It also introduces new requirements for periodic review of system performance and validation status, and expands on data integrity expectations in alignment with ALCOA+ principles [17]. The final versions of these documents are estimated to go live in mid-2026 [17].

- Enforcement Bodies: GMP compliance is overseen by the national competent authorities of member states, coordinated at the EU level by the European Medicines Agency (EMA).

United States (US) Regulatory Framework

The US Food and Drug Administration (FDA) regulates stem cell-based products primarily as biologics, with a strong emphasis on current Good Manufacturing Practices (cGMP).

- Key Guidelines: The foundational regulations for drugs and biologics are enshrined in 21 CFR Parts 210 and 211 [14]. The FDA's guidance documents, such as "Data Integrity and Compliance With Drug CGMP - Questions and Answers," provide further interpretation of these rules [19] [14]. The agency emphasizes a risk-based approach and the use of modern, validated systems, which is encapsulated in the term cGMP (current GMP) [14].

- Recent Updates: While the core regulations are stable, FDA enforcement data reveals trends. For FY2023, the agency intensified action on cGMP gaps and data integrity, issuing over 93 drug-quality-related import alerts [14]. For medical devices, including some combination products, a significant change is the upcoming effectiveness of the Quality Management System Regulation (QMSR) on February 2, 2026, which harmonizes FDA requirements with ISO 13485 [14].

- Enforcement Body: The FDA's Center for Biologics Evaluation and Research (CBER) is primarily responsible for regulating stem cell therapies.

Asian Regulatory Landscape

The Asian regulatory environment is diverse and rapidly evolving, with a growing emphasis on safety assessments and quality systems, though the focus in available literature is often on cosmetics as a proxy for a tightening regulatory environment.

- China: The National Medical Products Administration (NMPA) continues to enhance its regulatory framework. As of May 1, 2025, cosmetic companies are required to submit a full safety assessment report for product notification/registration, a move indicative of a broader trend towards greater scrutiny of product safety and documentation [20].

- South Korea: The Ministry of Food and Drug Safety (MFDS) is preparing to implement new cosmetic safety regulations from 2028, following a grace period. A forthcoming draft is expected to introduce new responsibilities for the Responsible Person (RP) and establish a new role of "safety assessor" [20].

- Taiwan: The Taiwan FDA (TFDA) has been aligning its Cosmetic Hygiene and Safety Act with international standards. The agency has rolled out a phased implementation schedule for Product Information Files (PIFs) and GMP compliance for manufacturing sites. Baby, lip, and eye products must establish PIFs and comply with GMP by July 1, 2025, with general cosmetics following a year later [20].

Table 1: Comparative Analysis of Key Regional GMP Frameworks for Biomanufacturing

| Aspect | European Union (EU) | United States (US) | Asia (Representative Examples) |

|---|---|---|---|

| Core Regulation | EudraLex Volume 4 (GMP) [21] | 21 CFR Parts 210, 211 (cGMP) [14] | Variable (e.g., Taiwan: Cosmetic Hygiene & Safety Act) [20] |

| Computerized Systems | Annex 11 (Under major revision) [17] | 21 CFR Part 11 (Electronic Records/Signatures) & CSA [17] | Often references or aligns with EU/US principles |

| Key 2025 Update | Draft Annex 11 (Cybersecurity, AI, Cloud) [17] [18] | QMSR harmonization with ISO 13485 (Effective 2026) [14] | China: Full safety assessment reports for cosmetics [20] |

| Data Integrity Focus | ALCOA+, embedded in PQS, audit trail review [18] | ALCOA, data integrity CGMP guidance [19] [14] | Increasingly emphasized (e.g., PIF requirements) [20] |

| Quality System Emphasis | Pharmaceutical Quality System (PQS) [18] | Quality System (cGMP) & QMSR for devices [14] | Good Manufacturing Practice (GMP) adoption [20] |

Essential Reagents and Materials for GMP-Compliant Stem Cell Research

Transitioning from research-grade to GMP-compliant materials is a critical step in clinical translation. The following table details key reagent solutions and their functions in a stem cell biomanufacturing context.

Table 2: The Scientist's Toolkit: Essential Reagents for GMP Stem Cell Biomanufacturing

| Reagent/Material Solution | Function in Stem Cell Biomanufacturing | GMP Compliance Consideration |

|---|---|---|

| GMP-Grade Human Pluripotent Stem Cells (hPSCs) | Starting material for differentiation into therapeutic cell types; requires rigorous characterization. | Must be sourced from a qualified supplier, accompanied by a comprehensive Certificate of Analysis (CoA) and tested for adventitious agents [16]. |

| Xeno-Free Culture Media | Provides nutrients and signaling molecules for cell growth and maintenance; excludes animal-derived components. | Raw materials must be qualified, and the final media formulation must be produced under a quality system. Full traceability and lot-to-lot consistency are critical. |

| GMP-Grade Growth Factors & Cytokines | Directs stem cell differentiation towards specific lineages (e.g., neural, cardiac). | Requires vendor qualification, CoA with data on purity, potency, and sterility. The definition of "GMP-grade" should be clearly understood and documented. |

| Cell Dissociation Reagents | Used for passaging adherent stem cells and harvesting cell products. | Must be compliant for human clinical use. The reagent's mechanism and any residual components must be shown to not impact cell safety or function. |

| GMP Plasmid DNA | Critical for the generation of induced Pluripotent Stem Cells (iPSCs) and gene-editing processes. | Sourced from a GMP plasmid service provider that ensures quality controls, documentation, and traceability throughout manufacturing [22] [23]. |

| Final Formulation Solutions (Cryopreservation Media) | Protects cell viability during freeze-thaw cycles for storage and transport. | Composition must be defined and validated. The cryopreservation and thawing process must be optimized and controlled to ensure consistent post-thaw cell recovery and function. |

Experimental Protocol for Establishing a GMP-Compliant Stem Cell Workflow

This protocol outlines the key methodological steps for establishing a scalable and GMP-compliant process for human pluripotent stem cell (hPSC) expansion, a foundational stage in stem cell biomanufacturing.

Protocol: Scalable Expansion of GMP-Compliant Human Pluripotent Stem Cells

Objective: To establish a validated, closed-system workflow for the expansion of GMP-grade hPSCs, ensuring maintenance of pluripotency and genetic stability for use in clinical trials.

Materials:

- GMP-grade hPSC Master Cell Bank (MCB) [16]

- Qualified, xeno-free hPSC culture medium and GMP-grade recombinant growth factors

- Closed-system bioreactor (e.g., suspension bioreactor) or multi-layer cell factories [16] [15]

- GMP-grade cell dissociation agent

- QC equipment for in-process monitoring (e.g., cell counter, flow cytometer, metabolyzer)

Methodology:

- System Preparation: Assemble the closed-system bioreactor or cell stack according to validated procedures. Prime the system with pre-warmed, GMP-grade culture medium. Ensure all environmental parameters (temperature, CO₂, humidity) are monitored and within specified ranges.

- Cell Seeding: Aseptically thaw a vial from the GMP-grade hPSC Working Cell Bank (WCB) following a validated protocol. Seed the cells into the prepared system at a pre-determined and optimized cell density.

- Controlled Expansion: Maintain the culture with periodic, automated medium exchange. Continuously monitor and record key process parameters (KPPs) such as pH, dissolved oxygen, and metabolite levels (e.g., glucose, lactate). The process should be designed to minimize manual intervention and open manipulations.

- In-process Monitoring: Take representative samples using aseptic, closed sampling systems.

- Perform daily cell counts and viability assessments.

- At specified intermediate stages, analyze samples for pluripotency markers (e.g., Oct4, TRA-1-60) via flow cytometry to ensure phenotypic stability.

- Harvest: Once the culture reaches the target cell density or confluence, terminate the expansion phase. Detach cells using a GMP-grade dissociation reagent and harvest using continuous centrifugation technologies (e.g., kSep, LOVO) [16].

- Formulation and Cryopreservation: Wash and resuspend the cell pellet in a defined, GMP-grade cryopreservation medium. Fill the final cell product into cryobags or vials using an automated filling system. Cryopreserve using a controlled-rate freezer and transfer to a validated, monitored liquid nitrogen storage system [16].

- Quality Control Testing: The final cell product must undergo rigorous QC testing, which typically includes, but is not limited to:

- Sterility testing (e.g., BacT/ALERT)

- Mycoplasma testing

- Identity testing (STR DNA profiling)

- Purity/Pluripotency analysis (Flow Cytometry)

- Potency assay (e.g., trilineage differentiation potential)

- Karyotype analysis to confirm genetic stability

The entire process, from cell thaw to final cryopreservation, must be conducted under the facility's quality system, with all activities documented in batch records and all data, including metadata and audit trails, retained in compliance with regional data integrity requirements [17] [18] [14].

Workflow Visualization: GMP-Compliant Stem Cell Biomanufacturing

The following diagram illustrates the logical workflow and the critical quality control checkpoints in a GMP-compliant stem cell biomanufacturing process.

Diagram 1: GMP stem cell manufacturing workflow with quality controls.

Workflow Visualization: Regulatory Strategy Across Regions

Developing a regulatory strategy requires understanding how regional frameworks interact with the product lifecycle. The following diagram outlines a logical approach for global regulatory alignment.

Diagram 2: Strategy for multi-regional GMP compliance.

The global regulatory landscape for GMP in stem cell biomanufacturing is dynamic and regionally distinct, yet converging on core principles of data integrity, risk management, and robust quality systems. The most significant changes are on the horizon in the EU, with a comprehensive modernization of Annex 11 that explicitly brings cloud, AI, and advanced cybersecurity under the GMP umbrella. For researchers and drug development professionals, proactive engagement is key. This involves conducting thorough gap analyses of current systems against these evolving standards, updating validation protocols and quality agreements, and investing in training for personnel. By integrating regulatory compliance as a foundational element of the research and development process, scientists can accelerate the translation of promising stem cell therapies from the laboratory bench to the patient bedside, navigating the complexities of the global market with confidence.

This document provides detailed application notes and protocols for establishing and maintaining controlled environments for aseptic processing, with a specific focus on applications in scalable stem cell biomanufacturing. Adherence to these principles is critical for ensuring the quality, safety, and efficacy of sterile cell-based therapies.

Regulatory Landscape and the Contamination Control Strategy (CCS)

The regulatory framework for sterile manufacturing has evolved to emphasize "built-in" quality over reliance on end-product testing. Key guidelines from the US FDA, WHO, and Health Canada now centralize the requirement for a holistic, living Contamination Control Strategy (CCS) [24]. A CCS is not a single document but a comprehensive plan that proactively links all contamination control measures—from raw materials to final product release [25] [24].

Table 1: Key Regulatory Pillars for Aseptic Processing in 2025

| Regulatory Authority | Guidance Document | Core Emphasis |

|---|---|---|

| US FDA | Guidance for Industry: Sterile Drug Products Produced by Aseptic Processing | Sterility is assured by process validation, not testing. Requires robust facility design, validated sterilization cycles, and rigorous personnel training [24]. |

| World Health Organization (WHO) | Annex 6: GMP for Sterile Pharmaceutical Products | Harmonized with global standards; mandates specific cleanroom grades (A-D) and details expectations for barrier technologies and the CCS [24]. |

| Health Canada | GUI-0119 (Annex to GMP Guide) | Provides granular expectations for environmental and process monitoring, stressing risk-based program design to detect process drift [24]. |

The CCS operates on a continuous cycle: Identify contamination risks, Assess the sufficiency of existing controls, Monitor performance with data, and Review & Improve the strategy periodically [24].

Facility Design and Critical Utilities

Modern facility design focuses on segregation and aerodynamic protection to minimize contamination risk.

Zoning, Airflow, and Pressure Cascades

Cleanrooms are classified into grades (A/B/C/D) that act as successive buffers. A robust pressure differential cascade (a minimum of 10-15 Pascals between adjacent zones) must be maintained to prevent lower-quality air from flowing into higher-grade areas [24].

Table 2: Cleanroom Classification and Environmental Limits

| Grade | ISO Equivalent | Airflow Principle | Maximum Permitted Particles (≥0.5μm/m³) | Microbial Action Limits (Settle Plates, Ø90mm, CFU/4 hours) |

|---|---|---|---|---|

| A | ISO 5 | Unidirectional (Laminar) | 3,520 | <1 [25] |

| B | ISO 7 | Turbulent (but filtered) | 352,000 | 5 [25] |

| C | ISO 8 | Turbulent | 3,520,000 | 50 [25] |

| D | ISO 9 | Turbulent | Not specified | 100 [25] |

Barrier Technologies: RABS vs. Isolators

Advanced barrier systems are increasingly favored to separate personnel from the process [24].

- Isolators: Provide complete physical separation. They allow for automated bio-decontamination (e.g., with Vaporized Hydrogen Peroxide) and can often operate in a less rigorous background environment (Grade C or D) [26] [24].

- RABS (Restricted Access Barrier Systems): Provide a rigid wall enclosure with glove ports but are not fully sealed. They rely on dynamic airflow and must be operated in a Grade B background [24].

Selection Guide: Isolators are preferred for high-potency drugs and maximum sterility assurance, while RABS offer more flexibility for faster product changeovers [24].

Personnel and Aseptic Behavior Control

The operator is the single greatest contamination risk. Controlling personnel is therefore paramount [24].

- Gowning: Sterile, non-shedding gowns that cover all skin are mandatory for Grade A/B entry. A formal gowning qualification program is required, with typical requalification occurring annually or more frequently following an excursion [25] [24].

- Aseptic Technique: Personnel must be rigorously trained in:

- Slow, deliberate movement to minimize turbulence.

- The "First Air" principle: Never obstruct the path of sterile HEPA air before it reaches the critical product surface.

- Minimal intervention: Processes should be designed to reduce or eliminate manual interventions [24].

Environmental and Process Monitoring

Monitoring verifies that the process is in a state of control but does not itself assure sterility [24].

Table 3: Elements of an Environmental Monitoring Program

| Monitoring Type | Method | Frequency (Example) | Key Parameter |

|---|---|---|---|

| Viable Air | Active Air Sampler (Volumetric) | Each operating shift | Colony Forming Units (CFU)/m³ |

| Viable Surface | Contact Plates (e.g., 55cm²) | Each operating session | CFU/plate |

| Viable Personnel | Finger Dabs, Gown Plates | Each exit from Grade A/B | CFU/plate |

| Non-Viable Particles | Real-time, continuous monitor | Continuously in Grade A | Particles (≥0.5μm and ≥5.0μm)/m³ |

Trend Analysis: Modern expectations require analyzing data trends over time to detect slow drifts in facility performance before they become major failures [27] [24].

Aseptic Process Simulation (Media Fill)

An Aseptic Process Simulation (APS), or media fill, is the ultimate validation of the aseptic process, using a sterile microbial growth medium in place of the actual product [25] [24].

Protocol 1: Aseptic Process Simulation (Media Fill) for a Stem Cell Suspension

- Objective: To demonstrate that the aseptic processing operations can produce sterile product.

- Frequency: Typically required semi-annually for each processing line and shift [24].

- Media: Tryptic Soy Broth (TSB) or another suitable sterile liquid growth medium.

- Procedure:

- The medium is subjected to the entire aseptic process, including thawing, dilution, transfer through closed systems or open manipulations under laminar airflow, and filling into final containers.

- The process must simulate "worst-case" conditions, including the maximum number of personnel, all permitted interventions, and the longest run duration.

- All containers are then incubated at 20-25°C for 7 days, followed by 30-35°C for 7 days.

- Acceptance Criteria: The target is zero growth-positive units. Any positive unit indicates a potential breach in sterility assurance and warrants a thorough investigation. The process typically requires three consecutive successful media fills to be requalified [24].

Protocol: GMP-Compliant Aseptic Thaw and Dilution of Cryopreserved Cells

This protocol outlines a standardized method for the aseptic preparation of cell therapy products, a common critical operation in stem cell biomanufacturing.

Stability Consideration: Studies on Wharton's Jelly-derived MSCs show that multiple freeze-thaw cycles and post-thaw storage at room temperature (20-27°C) lead to a significant decrease in cell viability and viable cell concentration. Thawed products should be processed as quickly as possible [28].

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 4: Key GMP-Compliant Reagents for Cell Biomanufacturing

| Reagent / Material | Function | GMP-Compliant Example / Specification |

|---|---|---|

| Human Platelet Lysate (hPL) | Serum-free, xeno-free cell culture supplement providing growth factors and attachment proteins. | GMP-grade, pathogen-inactivated [28]. Concentrations of 2% and 5% have shown similar efficacy for WJ-MSC expansion [28]. |

| GMP-Grade Enzymes | Isolation of cells from tissue matrices (e.g., umbilical cord Wharton's Jelly). | Collagenase NB6 GMP (Nordmark Biochemicals) at optimized concentrations (e.g., 0.4 PZ U/mL) [28]. |

| Defined, Xeno-Free Basal Medium | Base nutrient medium for cell culture and expansion. | Commercially available MSC Serum- and Xeno-Free Medium (e.g., NutriStem) [28]. |

| Sterile Disinfectants & Sporicides | For cleanroom and equipment decontamination. | A validated two-tier rotation system, including a sporicidal agent, is a regulatory expectation. Efficacy must be validated against environmental isolates [25] [24]. |

| Pre-Validated Aseptic Garments | To minimize particulate and microbial shedding from personnel. | Fabric selection and qualification are critical. A User Requirement Specification (URS) should be prepared for gowning systems [25]. |

Data Analytics and Continuous Improvement

Data analytics is crucial for optimizing GMP processes and enabling continuous improvement. It helps identify root causes of quality issues, monitor improvement outcomes, and foster a data-driven culture [27].

- Identifying Trends: Use real-time dashboards to track Key Performance Indicators (KPIs) like environmental monitoring data and media fill success rates to spot patterns and anomalies [27].

- Trend Analysis: Move beyond reacting to excursions. Analyze data trends over time to detect slow drifts in facility performance before they become failures [24].

The global stem cell market is experiencing robust growth, propelled by their expanding therapeutic applications in regenerative medicine, oncology, and drug discovery. The market size, valued at USD 16.74 billion in 2024, is projected to grow at a CAGR of 11.30% from 2025 to 2034, reaching approximately USD 48.83 billion by 2034 [29]. Concurrently, the stem cell manufacturing market is growing even faster, with an expected CAGR of 13.1%, aiming to reach USD 44.2 billion by 2034 from USD 12.9 billion in 2024 [30]. This growth is underpinned by rising demand for scalable, high-quality production of clinical-grade stem cells that comply with Good Manufacturing Practice (GMP) standards—a critical prerequisite for translating laboratory research into clinically applicable therapies [31] [32].

The transition from research-scale to industrial and clinical-scale stem cell production presents significant scientific and regulatory challenges. These include maintaining cell potency and genetic stability, controlling differentiation, ensuring reproducibility, and implementing rigorous quality control throughout the manufacturing process [33] [32]. This document outlines key market dynamics, provides detailed experimental protocols for GMP-compliant stem cell manufacturing, and explores the automated platforms and reagent solutions essential for scalable production.

Table: Global Stem Cell and Manufacturing Market Outlook

| Market Segment | 2024/2025 Base Value | Projected Value (2034) | CAGR | Primary Growth Driver |

|---|---|---|---|---|

| Overall Stem Cell Market [29] | USD 16.74 Billion (2024) | USD 48.83 Billion | 11.30% | Rising demand for regenerative medicines & expansion of clinical trials. |

| Stem Cell Manufacturing Market [30] | USD 12.9 Billion (2024) | USD 44.2 Billion | 13.1% | Advancements in biomanufacturing tech and rising chronic disease prevalence. |

| U.S. Stem Cell Market [29] | USD 5.75 Billion (2025) | USD 15.79 Billion | 11.90% | High R&D investment and concentration of biopharma companies. |

| Asia Pacific Manufacturing Market [30] | - | - | Fastest Growing | Strong product pipelines, government initiatives, and large patient pool. |

Market Dynamics and Regional Analysis

Key Market Drivers and Segmentation

The expansion of the stem cell market is fueled by several interconnected factors:

- Rising Therapeutic Applications: Stem cells hold significant promise for treating chronic and degenerative diseases, with the oncology segment exhibiting the highest growth rate due to various pipeline products [29]. The increasing prevalence of conditions like heart failure and diabetes is driving demand for regenerative therapies [30] [34].

- Technological Integration: The infusion of automation, artificial intelligence (AI), and advanced bioreactors is streamlining workflows, enhancing product consistency, and unlocking new revenue channels [35] [36]. AI is being utilized for predictive modeling, cell characterization, and quality control [37].

- Substantial Investments: Growing venture capital investment and favorable government initiatives are stimulating market growth, enabling cutting-edge research and the development of advanced manufacturing techniques [34].

Market segmentation reveals distinct trends. By product, adult stem cells, particularly Mesenchymal Stem Cells (MSCs), dominate due to lower contamination risks and better compatibility with the human body [29] [32]. By application, drug discovery and development is the largest segment, accounting for 53.8% of the manufacturing market in 2024, as stem cells enable more accurate, human-relevant biological assessments for pharmaceutical R&D [30].

Regional Landscape

The global stem cell market exhibits varied regional dynamics, influencing strategic expansion and collaboration opportunities.

Table: Regional Market Dynamics and Opportunities

| Region | Market Highlights & Drivers | Key Opportunities |

|---|---|---|

| North America [29] [30] | Leader with 44% market share (2024); strong R&D infrastructure; supportive regulatory framework; high concentration of pharma & biotech companies. | Enhancing scalable manufacturing platforms; leading innovation in automated bioprocessing and AI integration. |

| Asia-Pacific [29] [30] [37] | Fastest-growing market; driven by government support (e.g., China, Japan, South Korea), large patient pool, and rising healthcare investment. | Becoming a cost-effective manufacturing hub; expanding clinical trial activities; developing scalable production platforms for regional demand. |

| Europe [35] [37] | Mature market with strong focus on regulatory compliance and sustainability; advanced engineering and manufacturing bases in Germany, UK, and France. | Leading in green manufacturing technologies; fostering academia-industry collaborations for innovation. |

| Latin America [29] | Emerging market with promising growth in urban centers like São Paulo and Mexico City; challenges include regulatory heterogeneity and limited GMP capacity. | Establishing regional CDMO hubs; implementing tiered pricing strategies and local cryobanks to improve patient access. |

GMP-Compliant Protocol: Isolation and Expansion of Mesenchymal Stem Cells

The following section provides a detailed protocol for the GMP-compliant isolation and expansion of Mesenchymal Stem Cells (MSCs) from the infrapatellar fat pad (IFP), adapted from recent research [31]. The workflow below outlines the complete process from tissue acquisition to product release.

GMP-Compliant MSC Manufacturing Workflow

Reagents and Equipment

Source Tissue: Infrapatellar fat pad (IFP) tissue (10-20 g) obtained as surgical waste from patients undergoing anterior cruciate ligament (ACL) reconstructive surgery, following informed consent and ethical approval [31].

Critical Reagents:

- Collagenase (0.1% in serum-free media)

- GMP-compliant Culture Media: MSC-Brew GMP Medium (Miltenyi Biotec) or MesenCult-ACF Plus Medium (StemCell Technologies). These are animal component-free [31].

- Supplements: Human Platelet Lysate (hPL) where applicable, to replace Fetal Bovine Serum [32].

- Phosphate-Buffered Saline (PBS)

- Cryopreservation Solution: FBS containing 10% dimethyl sulfoxide [31].

Equipment:

- Class A/B cleanroom facility with laminar flow hoods [32]

- CO₂ Incubator

- Centrifuge

- Automated cell counter or Bright-Line Hemacytometer

- Flow Cytometer (for quality control)

- Automated Bioreactor Systems (e.g., Quantum, CliniMACS Prodigy) for large-scale expansion [32]

Step-by-Step Procedure

Tissue Digestion and Primary Cell Isolation

- Processing: Mince the acquired IFP tissue into approximately 1 mm³ pieces using sterile surgical instruments [31].

- Digestion: Incubate the minced tissue with 0.1% collagenase in serum-free media for 2 hours at 37°C with constant agitation [31].

- Cell Harvesting:

- Centrifuge the digested tissue at 300 × g for 10 minutes.

- Carefully remove the supernatant and surfactant layer.

- Resuspend the cell pellet in PBS and filter the suspension through a 100 μm filter to remove debris.

- Centrifuge again at 300 × g for 10 minutes and resuspend the final cell pellet in standard MSC media or the chosen GMP-compliant medium [31].

- Initial Seeding (Passage 0): Seed the isolated cells in culture flasks and incubate at 37°C with 5% CO₂.

- Medium Change: Replace the culture medium every 2-3 days to remove non-adherent cells.

Subculture and Expansion

- Passaging: Once cells reach 80-90% confluency, passage them using a standard trypsinization protocol.

- Expansion: Seed cells at a density of 5 × 10³ cells/cm² in the selected GMP-compliant medium for subsequent expansions [31].

- Large-Scale Culture: For clinical-scale production, transfer the process to an automated, closed-system bioreactor such as the Quantum or CliniMACS Prodigy system to enhance yield and maintain consistency while minimizing open manipulations [32].

Quality Control and Product Release Specifications

Rigorous quality control is fundamental to GMP. The final cell product must meet predefined release criteria before clinical application [31] [32].

Table: Quality Control Assays and Release Criteria for MSCs

| Test Category | Specific Assay / Marker | GMP Release Criteria | Purpose |

|---|---|---|---|

| Viability & Sterility | Trypan Blue Exclusion | > 95% Viability (Minimum >70%) [31] | Ensures metabolic competence of the final product. |

| Bact/Alert, Endotoxin, Mycoplasma | Sterile, No microbial contamination [31] | Confirms product safety, free from adventitious agents. | |

| Purity & Identity (Flow Cytometry) | Positive: CD73, CD90, CD105 | > 95% Positive Expression [31] [32] | Verifies MSC identity as per ISCT standards. |

| Negative: CD45, CD34, HLA-DR | < 5% Positive Expression [32] | Confirms absence of hematopoietic cells. | |

| Potency & Functionality | Colony Forming Unit (CFU) Assay | High colony formation capacity [31] | Demonstrates clonogenic and self-renewal potential. |

| Trilineage Differentiation (in vitro) | Differentiation into osteocytes, chondrocytes, adipocytes [32] | Confirms multilineage differentiation potential. | |

| Immunomodulatory Assay | Suppression of T-cell activation [32] | Validates therapeutic functionality for specific applications. |

Scaling Up: Automated Manufacturing Platforms

Automated closed-system bioreactors are pivotal for scaling up MSC production while adhering to GMP standards. They reduce labor intensity, minimize contamination risks, and improve process reproducibility [32]. The diagram below compares the core functions of two major automated platforms.

Automated Platform Comparison: Quantum vs. CliniMACS Prodigy

Table: Comparison of Automated Stem Cell Manufacturing Platforms

| Platform | Technology | Key Features | Process & Yield | GMP Compliance |

|---|---|---|---|---|

| Quantum (Terumo BCT) [32] | Hollow Fiber Bioreactor | Provides 21,000 cm² area; enables continuous medium exchange and hypoxia culture. | 7-day expansion yields 100-276 million BM-MSCs from a 20-million cell seed. | Closed, automated system reduces open manipulations from ~54,400 to 133 steps. |

| CliniMACS Prodigy (Miltenyi Biotec) [31] [32] | Integrated Tubing Set (TS730) with Adherent Cell Culture (ACC) | Fully automated from isolation and inoculation to harvest; uses MSC-Brew GMP medium. | 10-day procedure generates ~29-50 million MSCs at Passage 0 from primary tissue. | Integrated closed system ensures aseptic processing from start to finish. |

| Other Platforms (e.g., Xuri, Cocoon) [32] | Stirred-tank or fixed-bed bioreactors | Scalable wave-induced agitation or modular personalized therapy production. | Varies with system scale and cell type. | Designed as closed systems to meet GMP requirements for clinical production. |

The Scientist's Toolkit: Essential Reagent Solutions

The shift to GMP-compliant, scalable manufacturing requires a critical set of reagent solutions that ensure safety, consistency, and efficacy.

Table: Essential Research Reagent Solutions for GMP-Compliant Stem Cell Manufacturing

| Reagent Category | Specific Example | Function & Importance | GMP / Scalability Benefit |

|---|---|---|---|

| Culture Media | MSC-Brew GMP Medium [31] | Animal component-free medium formulated for MSC expansion. | Eliminates xeno-risks; ensures batch-to-batch consistency; compliant with regulatory standards. |

| Growth Supplements | Human Platelet Lysate (hPL) [32] | Replacement for Fetal Bovine Serum (FBS) as a growth supplement. | Animal-free; enhances cell proliferation; reduces immunogenicity risk in clinical applications. |

| Dissociation Enzymes | GMP-grade Collagenase [31] | Enzymatic digestion of tissues for primary cell isolation. | Traceable, non-animal origin versions available to ensure safety and quality of the cell product. |

| Critical Reagents | GM-grade DLL4 Protein [34] | Recombinant protein used in directing stem cell differentiation. | High-purity, well-characterized reagent crucial for consistent and controlled differentiation protocols. |

| Cryopreservation Media | Defined, Serum-Free Cryomedium | Protects cell viability and functionality during frozen storage. | Xeno-free formulation prevents contamination and maintains cell integrity post-thaw, critical for biobanking. |

The stem cell market's rapid growth is intrinsically linked to the successful development of robust, scalable, and GMP-compliant manufacturing processes. As documented herein, the market's double-digit growth trajectory is a powerful incentive for industry and academia to collaborate on standardizing protocols, optimizing culture conditions with animal-free reagents like MSC-Brew GMP Medium and hPL, and integrating automated platforms such as the Quantum and CliniMACS Prodigy systems. The detailed protocol and quality control framework provided serve as a foundational guide for researchers and drug development professionals aiming to translate stem cell innovations from the laboratory bench to the clinic, ultimately fulfilling the promise of regenerative medicine for a wider patient population.

Scalable Technologies and Automated Platforms for GMP-Compliant Production

The transition to Good Manufacturing Practice (GMP)-compliant biomanufacturing necessitates a shift from manual, open processes to automated, closed-system technologies [38] [9]. Automated bioreactor systems are central to this transition, enabling the standardization, scalability, and control required for the production of stem cell and T cell-based therapeutics [39] [40]. These systems minimize operator-dependent variability and reduce the risk of contamination, which is critical for meeting the stringent requirements of clinical-grade manufacturing [9] [41]. This document provides detailed application notes and experimental protocols for three prominent automated systems: the Quantum, CliniMACS Prodigy, and Cocoon platforms, framing their use within a scalable GMP biomanufacturing workflow.

System Profiles

- Quantum System (Cytiva): The Quantum is a hollow-fiber bioreactor designed for the rapid expansion of various cell types, including T cells. It is a functionally closed system that supports high-density cell culture, making it suitable for processes where cells are in the exponential growth phase [39].

- CliniMACS Prodigy (Miltenyi Biotec): The CliniMACS Prodigy is an integrated, automated platform that performs end-to-end manufacturing of cell therapies, from cell isolation and purification to transduction and expansion, within a single device [39] [40]. Its core technology includes magnetic separation for cell selection and an integrated culture chamber with pre-programmed process steps [39].

- Cocoon Platform (Lonza): The Cocoon Platform is a fully automated, closed-system designed for point-of-care (POC) or decentralized manufacturing of cell therapies [40]. It utilizes single-use, standardized "cassettes" or disposables to automate the entire manufacturing process, aiming to simplify production and ensure consistency in hospital or clinical settings [40].

System Comparison and Selection Guide

The table below summarizes the key operational characteristics of the three systems to aid in selection based on research and production goals.

Table 1: Quantitative Comparison of Automated Bioreactor Systems

| Feature | Quantum | CliniMACS Prodigy | Cocoon Platform |

|---|---|---|---|

| Primary Application | Rapid cell expansion once cells are in exponential growth [39] | End-to-end manufacturing from selection to final harvest [39] [40] | End-to-end automated manufacturing at the point of care [40] |

| Process Integration | Expansion only; requires upstream activation [39] | Fully integrated process (selection, activation, culture, harvest) [39] | Fully integrated process within single-use cassettes [40] |

| Target Cell Capacity | Information not available in search results | Up to (3 \times 10^9) target cells [39] | Information not available in search results |

| Manufacturing Model | Centralized | Centralized or Decentralized [39] [40] | Decentralized / Point-of-Care [40] |

| Key Automation Feature | Hollow-fiber technology for high-density culture [39] | Integrated magnetic selection and culture chamber [39] | Single-use, standardized cassette for closed processing [40] |

Experimental Protocols for GMP-Compliant Manufacturing

Protocol 1: T Cell Expansion using the Quantum System

This protocol assumes T cells have been previously isolated and activated.

- System Setup and Priming: Aseptically install the Quantum disposable cartridge and tubing set. Prime the system with pre-warmed cell culture medium according to the manufacturer's instructions to remove air bubbles and condition the circuit.

- Cell Inoculation: Harvest activated T cells and resuspend them in complete medium. Connect the cell bag to the system and initiate the inoculation sequence to load cells into the bioreactor cartridge. The recommended seeding density is highly process-dependent and should be optimized.

- Expansion Phase: The system continuously perfuses fresh medium through the hollow fibers while removing waste products. Monitor key parameters daily, including glucose consumption, lactate production, and gas exchange rates. Monitor cell growth through daily sampling and cell counting.

- Harvest: Once the target cell count or expansion fold is reached (typically after several days), initiate the harvest sequence. The system will wash and concentrate the cells into a final collection bag.

- Quality Control: Sample the final product for critical quality attributes (CQAs), including viability (target > 95%), cell count, sterility, and phenotype (e.g., CD3+, CD4+/CD8+ ratio) [39].

Protocol 2: CAR-T Cell Manufacturing on the CliniMACS Prodigy

This protocol describes an automated process for generating chimeric antigen receptor (CAR)-T cells from a starting apheresis product.

- Load Starting Materials: Aseptically load the leukapheresis product, appropriate GMP-grade buffers, and all required single-use sets (e.g., tubing set, culture bag) onto the CliniMACS Prodigy device [39].

- Cell Selection (Automated): Select the "CD4+/CD8+ Cell Selection" program. The system automatically performs density gradient centrifugation (if needed) and magnetic-activated cell sorting (MACS) using anti-CD4 and anti-CD8 microbeads, typically yielding a T cell population of >90% purity [39].

- Activation and Transduction (Automated): The system transfers the selected T cells to the integrated culture chamber. It then automatically adds T cell activation reagents (e.g., TransAct) and the viral vector for CAR gene transduction. The culture is maintained under controlled conditions with gentle agitation [39].

- Expansion (Automated): The system continues the culture, monitoring and maintaining parameters like temperature and gas exchange. The expansion typically continues for 7-10 days, with the system potentially performing media exchanges or feeds as programmed.

- Final Harvest and Formulation (Automated): Upon process completion, the system automatically washes and concentrates the CAR-T cells into a final bag, ready for fill-finish and cryopreservation. The entire process requires minimal hands-on time [39] [40].

Protocol 3: Point-of-Care Cell Therapy Production on the Cocoon Platform

This protocol outlines the use of the Cocoon for automated, decentralized manufacturing.

- Cassette Loading: In a GMP-compliant environment (potentially as low as Grade D), load the patient's starting material (e.g., purified T cells or PBMCs) and all required reagents into the single-use, pre-sterilized cassette [40] [42].

- System Initiation: Load the cassette into the Cocoon Platform. The system's software will automatically recognize the cassette and initiate the pre-validated manufacturing protocol.

- Hands-Off Processing: The platform is a functionally closed system, automating all subsequent unit operations. This includes cell activation, viral transduction, medium exchanges, and cell expansion within the bioreactor module. The system can incorporate in-process monitoring and controls to ensure product quality [40].

- Product Harvesting: After the prescribed culture period, the system automatically terminates the culture, washes the cells, and formulates the final therapeutic product into an infusion bag.

- Product Release and Administration: The final product is removed from the system and can undergo rapid, local quality control testing before being released for patient administration at the same site, significantly reducing vein-to-vein time [40].

The Scientist's Toolkit: Essential Reagents and Materials