GMP-Compliant Mesenchymal Stem Cell Isolation: A Feasibility Roadmap for Clinical Translation

The transition of mesenchymal stem cell (MSC) therapies from research to clinical application hinges on the establishment of robust, reproducible, and standardized Good Manufacturing Practice (GMP)-compliant isolation protocols.

GMP-Compliant Mesenchymal Stem Cell Isolation: A Feasibility Roadmap for Clinical Translation

Abstract

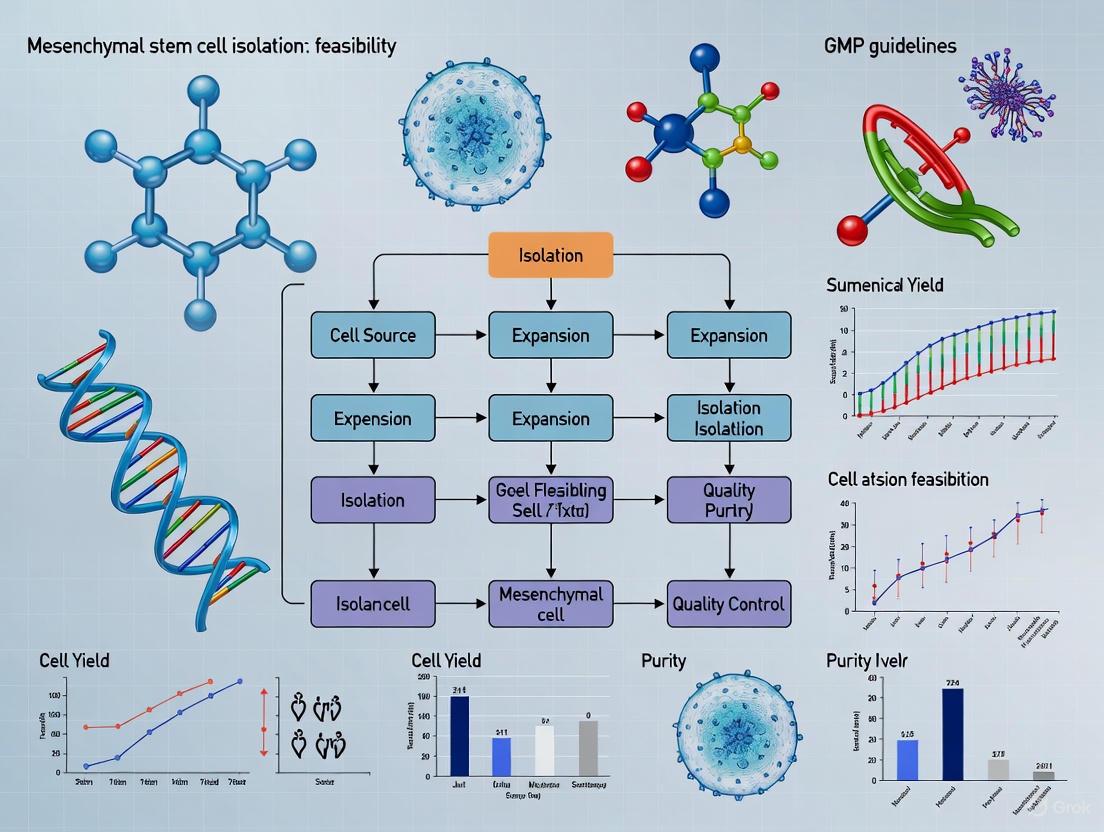

The transition of mesenchymal stem cell (MSC) therapies from research to clinical application hinges on the establishment of robust, reproducible, and standardized Good Manufacturing Practice (GMP)-compliant isolation protocols. This article provides a comprehensive analysis of the feasibility of GMP-grade MSC isolation, addressing the journey from foundational regulatory principles and donor selection to methodological optimization, troubleshooting of manufacturing hurdles, and final product validation. Tailored for researchers, scientists, and drug development professionals, it synthesizes current guidelines, explores advanced culture systems like xenogeneic-free media, and presents comparative data on MSC sources to equip stakeholders with the knowledge to navigate the complex pathway of producing clinical-grade MSCs for regenerative medicine.

Laying the Groundwork: GMP Principles and MSC Biology for Clinical Use

Defining GMP and Regulatory Frameworks for ATMPs (EMA & FDA)

Good Manufacturing Practice (GMP) is a quality assurance system that ensures medicinal products are consistently produced and controlled according to rigorous quality standards appropriate for their intended use [1]. In the context of Advanced Therapy Medicinal Products (ATMPs)—which encompass gene therapies, somatic cell therapies, and tissue-engineered products—GMP compliance is not merely a guideline but a legal requirement in many jurisdictions for products intended for human use [1] [2]. The European Medicines Agency (EMA) and the U.S. Food and Drug Administration (FDA) classify mesenchymal stem cell (MSC)-based products as ATMPs when they undergo substantial manipulation or are intended for a different essential function, placing them under stringent pharmaceutical legislation [1] [2].

The transition of promising MSC therapies from laboratory research to clinical application hinges on developing and implementing robust, reproducible, and GMP-compliant manufacturing processes [3] [4]. This guide details the core regulatory frameworks of the EMA and FDA, provides a practical breakdown of GMP requirements, and presents a validated experimental case study for the GMP-compliant isolation and expansion of MSCs, serving as a technical roadmap for researchers and drug development professionals.

Regulatory Framework for ATMPs

European Medicines Agency (EMA) Framework

The EMA regulates ATMPs through Regulation (EC) No 1394/2007, with the Committee for Advanced Therapies (CAT) serving as the central expert committee for their scientific assessment [2]. The EMA's centralized authorization procedure results in a single marketing authorization valid across the European Union (EU) and European Economic Area (EEA).

- Classification and Certification: The CAT provides recommendations on whether a product qualifies as an ATMP. For small and medium-sized enterprises (SMEs), the agency offers a certification procedure for quality and non-clinical data [2].

- Comprehensive Guidelines: The EMA has established an extensive set of scientific guidelines relevant to ATMP development. Key overarching guidelines include the "Guideline on human cell-based medicinal products" and the "Reflection paper on stem cell-based medicinal products" [5]. These cover all aspects from quality, non-clinical, and clinical development to environmental risk assessment.

- Support for Developers: The EMA provides various support mechanisms, including scientific advice, an ATMP pilot for academia and non-profit organizations, and fee incentives to encourage innovation and help developers meet regulatory requirements [2].

U.S. Food and Drug Administration (FDA) Framework

The FDA regulates cellular and gene therapy products through the Center for Biologics Evaluation and Research (CBER) under the authority of both the Public Health Service Act and the Federal Food, Drug, and Cosmetic Act [6].

- Risk-Based Approach: The FDA's regulatory framework is risk-based. Products that are minimally manipulated and intended for homologous use may be regulated solely under Section 361 of the PHS Act. In contrast, products that are more than minimally manipulated (like most MSC therapies) are regulated as biological drugs under Section 351 and require an approved Biologics License Application (BLA) [7].

- Detailed Guidance Documents: CBER has issued numerous specific guidance documents to assist sponsors. Recent draft guidances relevant to MSC therapies include "Safety Testing of Human Allogeneic Cells Expanded for Use in Cell-Based Medical Products" (April 2024) and "Considerations for the Use of Human- and Animal-Derived Materials in the Manufacture of Cell and Gene Therapy and Tissue-Engineered Medical Products" (April 2024) [7].

- Expedited Programs: The FDA offers expedited programs, such as the Regenerative Medicine Advanced Therapy (RMAT) designation, for therapies addressing serious conditions, which can accelerate development and review [7].

Table 1: Key Regulatory Bodies and Their Roles for ATMPs

| Agency | Governing Regulation | Key Committee/Office | Primary Authorization Route |

|---|---|---|---|

| European Medicines Agency (EMA) | Regulation (EC) No 1394/2007 | Committee for Advanced Therapies (CAT) | Centralized Marketing Authorization |

| U.S. Food and Drug Administration (FDA) | Public Health Service Act & Federal Food, Drug, and Cosmetic Act | Center for Biologics Evaluation and Research (CBER) | Biologics License Application (BLA) |

Core GMP Principles for ATMP Manufacturing

GMP guidelines are comprehensive, covering all aspects of production to ensure the safety, identity, purity, potency, and quality of the final medicinal product [1]. For ATMPs, which are often comprised of living cells, traditional GMP principles have been adapted to address their unique biological characteristics.

- Quality Management: A comprehensive system must be in place to oversee all aspects of production, from raw materials to final product release. This includes defined responsibilities, change control procedures, and self-inspection regimes.

- Facility and Equipment Control: Manufacturing must occur in controlled environments with defined air quality classifications (cleanrooms) to prevent microbial contamination and cross-contamination. Equipment must be qualified, calibrated, and maintained [1] [8].

- Material and Reagent Control: All starting and raw materials, including human and animal-derived materials (e.g., sera, enzymes), must be qualified and tested for quality and potential adventitious agents. The trend is strongly toward using xeno-free, GMP-grade reagents to mitigate risks [3] [4] [7].

- Process and Documentation Control: All manufacturing processes must be clearly defined, validated, and performed according to standard operating procedures (SOPs). Every step must be accurately and contemporaneously documented to ensure full traceability of the product and its components [1].

- Personnel and Training: All staff must be adequately qualified, trained, and competent in GMP principles and the specific techniques they perform.

- Product Testing and Release: The final product must undergo rigorous testing against predefined specifications. For MSC products, this includes, but is not limited to, viability, sterility (bacteria and fungi), mycoplasma, endotoxin, identity (via surface marker expression), and potency (a quantitative measure of biological activity) [3] [4] [7]. A positive quality control result is mandatory before product release.

Case Study: GMP-Compliant Isolation of Mesenchymal Stem Cells

A 2025 study titled "Optimizing mesenchymal stem cell therapy: from isolation to GMP-compliant expansion for clinical application" provides a practical blueprint for translating MSC research into a GMP-compliant process [3] [4]. The study focused on MSCs derived from the infrapatellar fat pad (FPMSCs), a less invasive source than bone marrow.

Experimental Protocol and Workflow

The methodology was designed with GMP compliance as a core objective, from tissue sourcing to final product cryopreservation.

Tissue Acquisition and Isolation

- Tissue Source: Infrapatellar fat pad (IFP) tissue was obtained as surgical waste from patients undergoing anterior cruciate ligament (ACL) reconstructive surgery, with full ethical approval and informed consent [4].

- Isolation Process: The IFP was minced and digested with 0.1% collagenase in serum-free media for 2 hours at 37°C. The digested tissue was centrifuged, washed, filtered, and the cell pellet was resuspended in culture media [4].

Culture Expansion and Media Comparison

- Media Formulations: The study compared a standard MSC media (with FBS) against two animal component-free, GMP-compliant media: MesenCult-ACF Plus Medium and MSC-Brew GMP Medium [4].

- Cell Culture: Cells were passaged at 80-90% confluency and seeded at a density of 5 × 10³ cells/cm². Critical quality attributes were assessed over multiple passages [4].

Analytical and Quality Control Methods

- Cell Doubling Time: Calculated at each passage to assess proliferation capacity [4].

- Colony Forming Unit (CFU) Assay: Cells were seeded at low densities (20-500 cells/dish) and grown for 10 days before staining with Crystal Violet to assess clonogenic potential, an indicator of stem cell potency [4].

- Flow Cytometry: Used to confirm MSC identity by analyzing the expression of standard positive (CD73, CD90, CD105) and negative (CD45) surface markers [4].

- Viability and Sterility Testing: Trypan Blue exclusion was used for viability counts. Sterility (bacterial/fungal contamination) was checked using the Bact/Alert system, while dedicated assays tested for Mycoplasma and Endotoxin [3] [4].

Key Quantitative Findings and Product Specifications

The study generated robust quantitative data demonstrating the success of the GMP-compliant process. The tables below summarize the key experimental results and the final product release criteria.

Table 2: Performance of FPMSCs in Different Culture Media [4]

| Culture Media | Doubling Time (Hours) | Colony Forming Unit (CFU) Capacity | MSC Marker Expression (CD73+/CD90+/CD105+) |

|---|---|---|---|

| Standard MSC Media (with FBS) | Baseline (Higher) | Baseline | Maintained |

| MesenCult-ACF Plus Medium | Intermediate | Intermediate | Maintained |

| MSC-Brew GMP Medium | Lowest (Enhanced Proliferation) | Highest (Enhanced Potency) | Maintained |

Table 3: GMP-FPMSC Final Product Release Specifications [3]

| Quality Attribute | Test Method | Release Specification | Study Result |

|---|---|---|---|

| Viability | Trypan Blue Exclusion | >70% | >95% |

| Sterility | Bact/Alert System | No Contamination | No Contamination Detected |

| Mycoplasma | Mycoplasma Assay | No Contamination | No Contamination Detected |

| Endotoxin | Endotoxin Assay | Below Specification | Below Specification |

| Identity/Purity | Flow Cytometry | Expression of MSC markers | CD45-, CD73+, CD90+, CD105+ |

| Stability | Post-thaw Viability | Maintains specifications | Stable for up to 180 days |

The data confirmed that MSC-Brew GMP Medium supported superior cell proliferation and potency compared to other media. Furthermore, the GMP-validation across four donors demonstrated that the final FPMSC product consistently met all critical quality attributes, with a viability exceeding 95% and stability maintained for up to 180 days of cryogenic storage, proving the robustness and reproducibility of the protocol [3].

The Scientist's Toolkit: Essential Reagents and Materials

Selecting the correct, GMP-compliant materials is fundamental to successful ATMP development. The following table details key reagents and their functions as utilized in the featured case study and related fields.

Table 4: Essential Research Reagent Solutions for GMP-Compliant MSC Manufacturing

| Reagent / Material | Function / Purpose | GMP-Compliant Example / Consideration |

|---|---|---|

| Animal Component-Free Media | Provides nutrients for cell growth and expansion while eliminating the risk of xenogenic immunogenicity and contamination. | MSC-Brew GMP Medium, MesenCult-ACF Plus Medium [4]. |

| Dissociation Enzymes | Breaks down tissue and dissociates adherent cells for passaging. | Use of GMP-grade, recombinant non-animal-derived collagenase [4] [7]. |

| Cell Separation Systems | Isulates, washes, and concentrates target cell populations in a closed, automated system. | Gibco CTS Rotea Counterflow Centrifugation System [8]. |

| Magnetic Cell Selection Systems | Isolates highly pure cell populations based on surface markers; removes magnetic beads after selection. | Gibco CTS Dynacellect Magnetic Separation System [8]. |

| Cryopreservation Medium | Protects cells from damage during freeze-thaw cycles. | Use of defined, serum-free, GMP-compliant cryomedium containing DMSO [3]. |

| Quality Control Assays | Tests for viability, sterility, mycoplasma, endotoxin, and cell identity to ensure product safety and quality. | Trypan Blue, Bact/Alert, Mycoplasma/Endotoxin kits, Flow Cytometry kits (e.g., BD Stemflow) [3] [4]. |

Navigating the GMP and regulatory landscapes for ATMPs is a complex but essential endeavor for translating MSC therapies from research to clinic. The EMA and FDA provide detailed, albeit distinct, frameworks designed to ensure patient safety and product efficacy. As demonstrated by the recent feasibility study on FPMSCs, success in this field is achievable through a meticulous approach that integrates GMP principles from the very beginning—from sourcing raw materials and optimizing culture conditions to establishing rigorous quality control protocols. By adhering to these frameworks and leveraging advanced, GMP-compliant tools and reagents, researchers and developers can significantly accelerate the development of safe and effective mesenchymal stem cell therapies for patients in need.

Core ISCT Criteria for MSCs and Implications for GMP Characterization

The field of Mesenchymal Stromal Cell (MSC) therapy has witnessed remarkable growth over the past decades, necessitating robust standards to ensure product quality and safety. The International Society for Cell and Gene Therapy (ISCT) established the fundamental criteria for defining MSCs, which have become the cornerstone for both research and clinical applications [9]. These criteria provide the essential foundation upon which Good Manufacturing Practice (GMP) characterization is built, creating a critical pathway for translating laboratory research into clinically viable therapies. The integration of ISCT's core definitions with GMP requirements represents a pivotal strategy for ensuring that MSC-based products are characterized with the rigor, consistency, and quality required for human administration, directly supporting the feasibility of MSC isolation and manufacturing within regulated clinical research frameworks [10].

The Core ISCT Criteria for Defining MSCs

The ISCT criteria, established to standardize the identity of MSCs across the field, are built upon three fundamental pillars that must be conclusively demonstrated for any cell population to be classified as MSCs.

The Three Definitive Pillars of MSC Identity

Adherence to Plastic: Under standard culture conditions, MSCs must demonstrate plastic adherence in vitro. This functional characteristic represents a primary, selective property whereby MSC populations are established and expanded from original tissue digests through their capacity to adhere to tissue culture plastic surfaces [9].

Specific Surface Marker Expression: MSCs must express a defined set of characteristic surface antigens while lacking expression of hematopoietic markers. Specifically, ≥95% of the cell population must express CD105, CD73, and CD90, while ≤2% of the population must lack expression of CD45, CD34, CD14 or CD11b, CD79α or CD19, and HLA-DR [9]. This immunophenotypic profile confirms the mesenchymal origin and purity of the cell population.

Multipotent Differentiation Potential: When induced under appropriate in vitro conditions, MSCs must possess the capacity to differentiate into osteoblasts, adipocytes, and chondroblasts. This trilineage differentiation potential provides functional validation of their stromal progenitor functionality [9].

Clarification of MSC Nomenclature

It is crucial to note the official nomenclature clarification by ISCT. While the term "Mesenchymal Stem Cells" remains popular in historical literature, the ISCT has officially defined the term MSC as "Mesenchymal Stromal Cells" for cells isolated from somatic or perinatal tissues based on the above criteria. This reflects the scientific consensus on their biological characteristics and helps distinguish them from truly pluripotent stem cells [9].

GMP Characterization: Translating Criteria into Clinical Grade

The transition from research-grade MSCs to clinically applicable products requires that the core ISCT criteria be evaluated within a GMP framework. This entails implementing rigorous, standardized, and well-documented processes that ensure product safety, purity, potency, and identity throughout manufacturing.

The GMP Imperative for Clinical Translation

The implementation of GMP standards is not merely regulatory compliance but a fundamental requirement for patient safety and therapeutic efficacy. As of 2023, only one MSC product (Ryoncil/Remestemcel-L) had received FDA approval, highlighting the significant challenges in translating MSC therapies to clinical application, largely due to the lack of standardized GMP protocols [10]. GMP compliance eliminates risks associated with animal-derived components, such as potential contamination, immunogenicity, and batch-to-batch variability, which is achieved through the use of animal-component-free media formulations [10]. Furthermore, GMP guidelines require stringent documentation and quality control at every stage, from tissue sourcing to final product release, ensuring process consistency and product reproducibility essential for credible clinical trials [10].

Applying ISCT Criteria Under GMP Standards

Each of the three ISCT pillars must be validated using GMP-compliant methods and specifications:

Plastic Adherence as a Selection Method: Within GMP processes, plastic adherence serves as the primary selection and purification method during initial isolation and expansion. The process must use GMP-grade culture vessels and be conducted in a controlled, aseptic environment [10] [9].

GMP-Compliant Phenotypic Characterization: Flow cytometry analysis for surface markers must utilize GMP-grade antibodies and standardized protocols. The equipment requires regular validation and calibration, and the analysis must include appropriate controls to ensure accuracy. The resulting data provides quantitative, lot-specific release criteria for product identity and purity [10].

Potency Assessment through Differentiation: The trilineage differentiation assay transitions from a qualitative identity test to a quantitative potency assay under GMP. This requires standardized, validated differentiation kits and scoring methods to demonstrate biological activity, with established acceptance criteria for the degree of differentiation achieved [10].

Quantitative GMP Characterization Data and Standards

The implementation of GMP standards establishes specific, quantitative benchmarks for product release. The following table summarizes key characterization data and acceptance criteria derived from GMP validation studies.

Table 1: Quantitative Specifications for GMP-Compliant MSC Characterization

| Characterization Parameter | Test Method | GMP Release Criteria | Experimental Data from GMP Validation [10] |

|---|---|---|---|

| Viability | Trypan Blue Exclusion | >70% minimum requirement | >95% viability post-thaw |

| Sterility | Bact/Alert & Mycoplasma Assay | No contamination detected | Sterility maintained up to 180 days of storage |

| Identity & Purity | Flow Cytometry | ≥95% CD105, CD73, CD90+≤2% CD45, CD34, CD14, CD19, HLA-DR+ | Maintained marker expression post-thaw and across passages |

| Potency | Colony Forming Unit (CFU) Assay | Colony formation capacity | Higher CFU in GMP media (MSC-Brew) vs. standard media |

| Proliferation | Population Doubling Time | Established baseline for cell line | Lower doubling times in MSC-Brew GMP Medium |

| Safety | Endotoxin Assay | Below specified limit | Within acceptable limits for clinical administration |

Advanced GMP Characterization Metrics

Beyond the basic release criteria, comprehensive GMP characterization includes additional critical quality attributes (CQAs) that ensure product consistency and functionality.

Table 2: Advanced Critical Quality Attributes for GMP-Compliant MSCs

| Critical Quality Attribute (CQA) | Analytical Method | Significance for Clinical Feasibility |

|---|---|---|

| Cell Count & Dosage | ISO Cell Counting Standards [11] | Ensures accurate dosing; may shorten regulatory review |

| Karyotype Stability | Karyotyping/G-banding | Confirms genetic stability after extended culture |

| Immunomodulatory Function | Mixed Lymphocyte Reaction (MLR) [9] | Validates mechanistic potency for autoimmune applications |

| Secretome Profile | ELISA/Multiplex Assays | Quantifies trophic factor production (e.g., IDO, IL) |

| Post-Thaw Recovery | Viability & Function Assays | Validates cryopreservation protocol and product shelf-life |

| Morphology & Adherence | Microscopy & Imaging | Confirms typical fibroblast-like morphology and plastic adherence |

Experimental Protocols for GMP-Compliant Characterization

GMP-Compliant Isolation and Culture Protocol

The feasibility of MSC isolation under GMP hinges on rigorously validated protocols. The following workflow outlines a standardized method for deriving clinical-grade MSCs from tissue sources, incorporating data from a 2025 study on infrapatellar fat pad-derived MSCs (FPMSCs) [10].

Key Protocol Details:

- Tissue Source: Infrapatellar fat pad (IFP) tissue acquired as waste tissue from reconstructive surgery, with donor screening and informed consent [10].

- Digestion: 0.1% collagenase in serum-free media for 2 hours at 37°C [10].

- GMP Media Validation: Comparative studies show MSC-Brew GMP Medium (Miltenyi Biotec) supports enhanced proliferation rates and colony formation compared to standard media and other animal-free formulations like MesenCult-ACF Plus Medium [10].

- Culture Conditions: Seeding density of 5 × 10³ cells/cm² and passaging at 80-90% confluency [10].

- Quality Control: Incorporation of sterility testing (Bact/Alert, Mycoplasma assays) and endotoxin testing throughout the process [10].

Analytical Methods for ISCT Criterion Verification

The following workflow details the specific analytical methods required to verify that the isolated cells meet all three ISCT criteria within a GMP-compliant framework.

Key Analytical Details:

- Flow Cytometry: Utilization of standardized kits such as the BD Stemflow Human MSC Analysis Kit with gating strategies established for consistency across batches [10].

- Potency Assays: Differentiation kits must be GMP-grade, and staining protocols must be standardized with established scoring criteria to quantitatively assess differentiation potential.

- Additional Testing: The GMP framework also requires karyotype analysis to rule out genetic abnormalities and sterility testing to ensure the product is free from microbial contamination [10].

Essential Research Reagent Solutions for GMP Characterization

The feasibility of GMP-compliant MSC characterization depends on the use of specific, quality-controlled reagents. The following table catalogues essential materials and their functions based on cited protocols.

Table 3: Research Reagent Solutions for GMP-Compliant MSC Workflows

| Reagent Category | Specific Product Examples | GMP-Compliant Function |

|---|---|---|

| Animal-Free Media | MSC-Brew GMP Medium (Miltenyi Biotec) [10]MesenCult-ACF Plus Medium (StemCell Technologies) [10] | Supports expansion & maintenance; eliminates xeno-contamination risks |

| Dissociation Enzymes | Collagenase (0.1%) [10] | Tissue dissociation for primary cell isolation |

| Characterization Kits | BD Stemflow Human MSC Analysis Kit (BD Biosciences) [10] | Standardized immunophenotyping for ISCT surface markers |

| Differentiation Kits | Trilineage Differentiation Kits (Various GMP Suppliers) | Validated induction of osteogenic, adipogenic, and chondrogenic lineages |

| Cryopreservation Media | FBS with 10% DMSO [10] | Long-term storage while maintaining post-thaw viability and function |

| Quality Control Assays | Bact/Alert, Mycoplasma Assay, Endotoxin Test [10] | Ensures product sterility and safety for clinical use |

The integration of core ISCT criteria with rigorous GMP characterization protocols provides a essential roadmap for the feasible development of clinically relevant MSC-based therapies. The ISCT standards establish the fundamental biological identity of MSCs, while GMP requirements translate these definitions into a framework of quality, safety, and consistency. As the field advances, with emerging sources such as infrapatellar fat pad-derived MSCs [10] and induced pluripotent stem cell-derived MSCs [9] demonstrating promise, adherence to this combined standard will remain paramount. The continued refinement of these characterization protocols, guided by both ISCT and regulatory bodies, will undoubtedly enhance the feasibility, reproducibility, and ultimate success of MSC isolation and manufacturing for clinical research and therapeutic application.

Mesenchymal stromal cells (MSCs) represent a cornerstone of regenerative medicine and immunotherapeutic research due to their multipotent differentiation capabilities, immunomodulatory properties, and paracrine activity [12]. The International Society for Cell & Gene Therapy (ISCT) has established critical criteria for defining MSCs, including plastic adherence, specific surface marker expression (CD73+, CD90+, CD105+, CD45-, CD34-, CD14- or CD11b-, CD79α- or CD19-, HLA-DR-), and trilineage differentiation potential (osteogenic, adipogenic, chondrogenic) [13] [12]. For clinical applications, particularly in the European Union and Germany, MSC-based products are classified as Advanced Therapy Medicinal Products (ATMPs) and must be manufactured under strict Good Manufacturing Practice (GMP) standards to ensure quality, safety, and efficacy [13]. This manufacturing process requires a formal license and adherence to comprehensive quality control measures, making the choice of MSC source a critical determinant in the feasibility and scalability of GMP-compliant production [13] [14].

MSCs can be isolated from multiple tissue sources, with bone marrow (BM), adipose tissue (AT), and umbilical cord (UC), specifically Wharton's Jelly (WJ), being the most extensively studied. Each source presents distinct advantages and limitations in the context of GMP-compliant manufacturing for clinical applications.

Table 1: Comparative Characteristics of MSC Sources for GMP-Compliant Manufacturing

| Feature | Bone Marrow (BM) | Adipose Tissue (AT) | Umbilical Cord (WJ) |

|---|---|---|---|

| Tissue Availability | Invasive harvest; limited donor supply [4] | Minimally invasive harvest (e.g., liposuction); relatively abundant [4] [12] | Medical waste; non-invasive collection; easily accessible [15] |

| Cell Yield & Proliferation | Lower yield; slower proliferation (e.g., DT: ~99 hrs) [16] | High yield; moderate proliferation (e.g., DT: ~40 hrs) [16] | High yield; rapid proliferation (e.g., DT: ~21 hrs) [15] [16] |

| Immunomodulatory Potency | High immunomodulatory activity [16] | Moderate immunomodulatory activity [16] | Moderate immunomodulatory activity [16] |

| Therapeutic Secretome | Lower secretion of some neurotrophic factors [16] | Favorable secretome profile for neuroregeneration [16] | Favorable secretome profile for neuroregeneration [16] |

| Risk of Contamination | Risk from hematopoietic cells [13] | - | Low immunogenicity; reduced ethical concerns [15] |

Table 2: Functional and Therapeutic Potential of Different MSC Sources

| Parameter | Bone Marrow (BM-MSCs) | Adipose Tissue (AT-MSCs) | Umbilical Cord (WJ-MSCs) |

|---|---|---|---|

| Immunosuppression (Contact) | Strong inhibition up to PBMC:MSC ratio 40:1 [16] | Inhibition at lower ratios only (e.g., 10:1) [16] | Inhibition at lower ratios only (e.g., 10:1) [16] |

| Immunosuppression (Non-Contact) | Strong inhibition up to PBMC:MSC ratio 5:1 [16] | Limited non-contact inhibition [16] | Limited non-contact inhibition [16] |

| Neurotrophic Potential | Moderate | High | High |

| Clinical-Grade Expansion | Challenging due to slower growth [16] | Feasible with optimized protocols [4] | Highly feasible; excellent scalability [15] |

| Donor Variability | Subject to age-related decline [17] | - | Consistent "younger" cell phenotype [15] |

GMP-Compliant Isolation and Culture Methodologies

Transitioning from research-grade to clinical-grade MSC manufacturing necessitates stringent protocols that eliminate animal-derived components and ensure batch-to-batch consistency.

Donor Selection and Tissue Sourcing

For BM-MSCs, a minimum of 10–20 mL of bone marrow aspirate is typically required for successful isolation [13]. Donors must be thoroughly screened for transmissible diseases, and the resulting cell population is inherently heterogeneous [13]. For WJ-MSCs, umbilical cords are collected post-cesarean section from mothers aged 20–35 who are free from infectious diseases and have provided written informed consent [15]. The cord is transported at 2–10°C and processed within 24 hours, followed by decontamination and vessel removal to isolate Wharton's jelly [15].

Isolation Techniques

Two primary isolation methods are employed:

- Enzymatic Digestion: For WJ-MSCs, optimal isolation parameters include using 0.4 PZ U/mL of GMP-grade collagenase (e.g., Collagenase NB6) with a digestion time of 3 hours at 37°C [15]. This method yields a high number of primary (P0) cells and is generally faster than the explant method [15].

- Explant Method: This technique involves mincing the tissue into small fragments (1–4 mm³) and culturing them directly. It is simpler and minimizes exposure to enzymes but can be more challenging to standardize and may have a slower initial outgrowth [15].

Culture Medium and Supplements

A critical step in GMP compliance is moving away from fetal bovine serum (FBS) due to risks of immunogenicity and pathogen transmission [13] [14]. Current GMP-compliant strategies include:

- Human Platelet Lysate (hPL): Serves as a effective xeno-free supplement. Studies show that concentrations of 2% to 5% hPL can effectively support MSC expansion [4] [15]. However, hPL is a crude derivative that can exhibit batch-to-batch variation and must be sourced from pathogen-screened donors, sometimes requiring pooling to minimize variability [14].

- Defined Serum-Free/Xeno-Free Media: Commercially available formulations like MSC-Brew GMP Medium and MesenCult-ACF Plus Medium provide a fully defined environment [4]. Research demonstrates that MSCs cultured in MSC-Brew GMP Medium exhibit enhanced proliferation rates and colony-forming capacity compared to standard media [4].

Diagram 1: GMP-Compliant MSC Manufacturing Workflow

Expansion and Scalability

For large-scale clinical applications, traditional flask-based culture is insufficient. Bioprocess engineering using bioreactors for 3D culture provides a controlled microenvironment that can improve stem cell yield, function, and safety under cGMP [18]. Studies show that passages 2 to 5 (P2-P5) are optimal for WJ-MSCs, exhibiting high viability and proliferation ability, while extended passaging should be avoided to prevent senescence [4] [15]. The population doubling time of WJ-MSCs (approximately 21 hours) is significantly lower than that of BM-MSCs (approximately 99 hours), facilitating more efficient scale-up [16].

Quality Control and Functional Validation

Robust quality control is indispensable for GMP-compliant MSC manufacturing. This extends beyond basic characterization to include functional potency assays.

Release Criteria and Testing

- Viability and Sterility: Post-thaw cell viability should exceed 95% [4]. Products must undergo sterility testing (e.g., using Bact/Alert systems) and mycoplasma and endotoxin assays [4].

- Immunophenotyping: Flow cytometry must confirm expression of CD73, CD90, and CD105 on >90% of cells, and lack of expression of CD45, CD34, CD14/CD11b, CD79α/CD19, and HLA-DR on >98% of cells, as per ISCT guidelines [13] [12]. The 2025 ISCT standards emphasize quantitative reporting of these markers [19].

- Karyotyping and Tumorigenicity Testing: Genetic stability must be verified to ensure safety, particularly after extensive in vitro expansion [13].

- Potency Assays: These are critical quality attributes (CQAs) that should reflect the intended clinical mechanism of action. For immunomodulatory applications, this could involve measuring the suppression of peripheral blood mononuclear cell (PBMC) proliferation [13] [16]. The new 2025 ISCT standards specifically require the assessment of efficacy and functional properties as CQAs [19].

Emerging Biomarkers: Cellular Deformability

Recent research highlights cellular deformability—a cell's ability to change shape under force—as a novel, integrative biomarker for MSC quality [17]. It correlates with therapeutic attributes such as stemness, homing efficiency, and differentiation status [17]. MSCs with higher deformability show greater migration and secretory potential, while stiffer cells are often associated with aging and differentiation [17]. Techniques like real-time deformability cytometry (RT-DC) offer high-throughput analysis for quality control, potentially enabling the enrichment of therapeutically potent MSC subpopulations and reducing product heterogeneity [17].

Essential Research Reagent Solutions for GMP-Compliant MSC Culture

Table 3: Key Reagents for GMP-Compliant MSC Manufacturing

| Reagent Category | Example Products | Function & Importance |

|---|---|---|

| Basal Media | MEM-α, DMEM | Provides essential nutrients and salts for cell growth and maintenance. |

| Xeno-Free Supplements | Human Platelet Lysate (hPL), MSC-Brew GMP Medium | Replaces FBS to eliminate xenogenic risks; promotes expansion under defined conditions [4] [14]. |

| GMP-Grade Enzymes | Collagenase NB6 | Used for tissue dissociation during isolation; critical for yield and viability [15]. |

| Cell Dissociation Agents | Trypsin-EDTA, TrypLE | Detaches adherent cells for passaging and subculture. |

| Cryopreservation Media | DMSO-containing formulations with serum-free base | Preserves cell viability and functionality during long-term storage. |

The feasibility of GMP-compliant isolation and expansion of MSCs is highly dependent on the selected tissue source. Bone marrow-derived MSCs, while functionally potent, present challenges in scalability due to invasive harvesting and slower proliferation. Adipose tissue offers a viable alternative with higher cell yields and less invasive collection. Wharton's jelly-derived MSCs from the umbilical cord emerge as a highly promising source, characterized by rapid proliferation, ease of access without ethical concerns, and robust performance in scalable, GMP-compliant manufacturing processes [15] [16].

Future advancements in MSC therapy will be driven by the implementation of revised ISCT standards [19], the adoption of advanced functional biomarkers like cellular deformability [17], and the continued refinement of bioprocessing techniques in bioreactors [18]. The integration of these elements will ensure the consistent production of high-quality, safe, and potent MSC-based therapeutics, ultimately fulfilling their potential in regenerative medicine.

The feasibility of isolating and manufacturing mesenchymal stem cells (MSCs) under Good Manufacturing Practice (GMP) standards is critically dependent on rigorous donor selection criteria. Donor characteristics significantly impact the functional properties, therapeutic potency, and overall quality of the final MSC product [20] [21]. This technical guide examines the core considerations for donor eligibility—specifically age, health status, and ethical compliance—framed within the context of GMP-compliant MSC isolation for clinical applications. As MSC therapies transition from research to clinical use, establishing standardized, evidence-based donor selection protocols becomes paramount for ensuring product safety, efficacy, and reproducibility [21] [22].

The inherent heterogeneity of MSC populations, substantially influenced by donor-specific factors, presents a major challenge in producing standardized cell therapy products [20] [23]. Selecting the appropriate MSC donor is particularly crucial when developing allogeneic "off-the-shelf" therapies, where cells from a single donor are expanded for multiple recipients [21] [24]. This guide synthesizes current research and regulatory expectations to provide a comprehensive framework for donor evaluation in GMP-compliant MSC manufacturing.

Impact of Donor Age on MSC Characteristics

Donor age is a primary consideration in donor selection, with substantial evidence indicating its influence on MSC proliferation, differentiation potential, and senescence. However, the relationship is complex and varies across tissue sources and species.

Proliferation and Senescence

Table 1: Impact of Donor Age on MSC Proliferation Capacity

| Age Group | Species/Breed | Proliferation Capacity | Research Findings |

|---|---|---|---|

| Fetal | Bovine (Holstein Friesian) | High | 6 of 7 donors surpassed 30 population doublings [20] |

| Calf | Bovine (Holstein Friesian) | High | 4 of 7 donors surpassed 30 population doublings [20] |

| Adult | Bovine (Holstein Friesian) | Reduced | Lower proliferation capacity compared to fetal and calf [20] |

| Aged (≥60 years) | Human | Significantly Reduced | Decreased proliferative potential and increased senescence [24] |

MSCs from younger donors generally demonstrate enhanced proliferative capacity and delayed senescence. In bovine models, fetal and calf MSCs from Holstein Friesian breeds showed superior population doubling capacity, with most donors exceeding 30 population doublings [20]. Similarly, human bone marrow-derived MSCs (BM-MSCs) from older donors (60-80 years) exhibit reduced proliferative potential and increased morphological changes associated with senescence compared to those from younger donors (30-40 years) [24]. This decline is attributed to accumulated oxidative stress and reduced antioxidant defense mechanisms in aged cells [24].

Differentiation Potential

Table 2: Age-Related Changes in MSC Differentiation Potential

| Lineage | Age Effect | Research Evidence |

|---|---|---|

| Osteogenic | Variable (Decreased in Aged) | Slight negative correlation of alkaline phosphatase (ALP) expression with donor age in human BM-MSCs; breed effect more prominent than age in bovine MSCs [20] [25] |

| Adipogenic | Variable | Higher potential in fetal and adult bovine MSCs (Holstein Friesian); decreased potential in aged human BM-MSCs and gingival MSCs [20] |

| Chondrogenic | Generally Decreased | Significantly reduced potential with increasing age in human studies [20] |

The effect of donor age on differentiation potential is lineage-dependent and shows considerable variation. While some studies report a slight negative correlation between donor age and osteogenic differentiation in human BM-MSCs, evidenced by reduced alkaline phosphatase expression [25], other research suggests that breed or species differences may outweigh age effects [20]. Chondrogenic differentiation appears to consistently decline with increasing donor age across multiple studies [20].

Molecular Signature of Aging

Genome-wide expression analyses of human BM-MSCs from donors aged 17-84 have identified specific genetic markers correlated with aging, despite considerable donor-to-donor variation in clinical parameters and in vitro performance [25]. These molecular signatures provide potential tools for assessing MSC quality and "biological age" beyond chronological age, which could be valuable for standardizing donor selection in GMP manufacturing.

Figure 1: Relationship between donor age and MSC functional characteristics. Aging negatively impacts proliferation and increases senescence, while differentiation effects vary. Molecular changes include increased oxidative stress and specific genetic markers.

Health Status and Biological Factors

Beyond chronological age, the overall health status and biological characteristics of donors significantly influence MSC quality and must be carefully evaluated for GMP-compliant manufacturing.

Donor Health and Medical History

Comprehensive donor screening is essential to exclude individuals with conditions that might compromise MSC quality or pose safety risks to recipients. Key considerations include:

- Infectious Disease Screening: Donors must be screened for transmissible diseases following standard blood and tissue banking protocols [22].

- Comorbidities and Medications: Underlying health conditions and pharmacological treatments may alter MSC functionality, though specific criteria remain poorly defined [21].

- Genetic Stability: The risk of karyotypic abnormalities may be higher in older or diseased donors, though it is unclear whether this is intrinsic or results from ex vivo expansion [21].

Sex and Gender Effects

Emerging evidence indicates that donor sex influences MSC properties, including differentiation potential, proliferation capacity, secretome profile, and therapeutic efficacy [21] [24]. While not yet standardized in all protocols, sex-matching between donor and recipient may optimize outcomes for specific applications, particularly in autoimmune disease treatment [24].

Tissue Source Considerations

The tissue origin of MSCs introduces another variable in donor selection, as biological source significantly impacts MSC characteristics:

- Bone Marrow: Traditionally considered the "gold standard" but requires invasive extraction with risk of patient morbidity [4] [22].

- Adipose Tissue: Abundant MSC yield with less invasive collection procedures; cells may express CD34 in early passages [20] [22].

- Infrapatellar Fat Pad: Less characterized source with practical advantages for orthopedic applications; can be harvested with minimal invasiveness during knee surgery [4].

- Neonatal Tissues (placenta, umbilical cord, Wharton's jelly): Considered more primitive MSCs but with practical challenges in consistent collection [22].

Ethical Framework and Regulatory Compliance

Ethical donor selection and adherence to regulatory guidelines are fundamental to GMP-compliant MSC manufacturing, ensuring patient safety and maintaining public trust.

Core Ethical Principles

The International Society for Stem Cell Research (ISSCR) outlines fundamental principles for stem cell research and clinical translation, emphasizing integrity, patient welfare, respect for research subjects, transparency, and social justice [26]. These principles provide an ethical foundation for donor selection protocols.

Informed Consent Process

Valid informed consent represents a cornerstone of ethical MSC donation, particularly for personalized medicine approaches using autologous cells [27]. Key elements include:

- Voluntary Participation: Donors must provide consent without coercion, based on comprehensive understanding of the donation process and intended use [27] [26].

- Altruistic Donation: European standards emphasize altruism and solidarity between donor and recipient, encouraging voluntary unpaid donations to enhance safety standards [27].

- Anonymity: Maintenance of donor and recipient anonymity is typically required, except in autologous applications [27].

Regulatory Landscape

Table 3: Regulatory Framework for MSC-Based Therapies

| Region | Regulatory Classification | Governing Documents | Key Requirements |

|---|---|---|---|

| European Union | Advanced Therapy Medicinal Product (ATMP) | Regulation 1394/2007/EC; Directive 2009/120/EC; EudraLex Volume 4 [21] [22] | GMP compliance; centralized marketing authorization; specific technical requirements |

| United States | Human Cells, Tissues, and Cellular/Tissue-Based Products (HCT/Ps) | Code of Federal Regulations (CFR) Title 21, Parts 1271 [22] | Current Good Tissue Practice (cGTP); establishment registration; donor eligibility determination |

MSCs are classified as Advanced Therapy Medicinal Products (ATMPs) in Europe and subject to specific FDA regulations in the United States [21] [22]. Both regulatory frameworks require rigorous donor eligibility determination, screening, and testing to prevent transmission of communicable diseases [22]. The complex regulatory environment represents a significant challenge for academic institutions and small-to-medium enterprises (SMEs) developing MSC therapies [21].

Figure 2: Ethical and regulatory framework for donor selection in MSC manufacturing. Core ethical principles, informed consent requirements, and regional regulations govern donor eligibility.

GMP-Compliant Donor Selection Workflow

Implementing a standardized, documented workflow for donor selection is essential for GMP-compliant MSC manufacturing. This systematic approach ensures consistency, traceability, and quality of the final cell product.

Donor Screening Protocol

A comprehensive donor screening protocol should integrate multiple criteria to assess donor suitability:

- Age Evaluation: Documented verification of donor age with consideration for the intended therapeutic application (e.g., preference for younger donors for allogeneic banking) [20] [24].

- Medical History Review: Comprehensive assessment of current and past medical conditions, medications, and potential risk factors [21].

- Infectious Disease Testing: Required serological and molecular testing for relevant blood-borne pathogens [22].

- Lifestyle Risk Assessment: Evaluation of behavioral factors that might increase transmission risk [22].

Documentation and Traceability

GMP requirements mandate complete documentation of all donor selection decisions, including:

- Donor eligibility determination records

- Informed consent documentation

- Testing results and interpretation

- Deviation documentation and justification

This documentation ensures full traceability from original donor to final MSC product, a fundamental requirement for ATMPs [21] [22].

Experimental Protocols for Donor Evaluation

Rigorous experimental assessment of donor-derived MSCs provides critical data for evaluating donor suitability and establishing release criteria for clinical-grade cell banks.

proliferation and Senescence Assays

Protocol: Population Doubling Time Calculation

- Objective: Quantify in vitro proliferation capacity of donor MSCs [20] [4].

- Methodology:

- Seed MSCs at standardized density (e.g., 5,000 cells/cm²) [4].

- Culture until 70-90% confluency in defined media.

- Harvest and count cells using validated method (e.g., hemocytometer, automated cell counter).

- Repeat for multiple passages to establish growth kinetics.

- Calculate doubling time using the formula:

( Doubling\ Time = \frac{duration \times \ln{2}}{\ln{(final\ concentration / initial\ concentration)} } ) [4].

- GMP Considerations: Use defined, xenogeneic-free media (e.g., MSC-Brew GMP Medium, MesenCult-ACF Plus Medium) to ensure clinical compatibility [4].

Protocol: Senescence-Associated β-Galactosidase Staining

- Objective: Detect senescent cells in donor MSC populations [20].

- Methodology:

- Culture MSCs on chamber slides until subconfluent.

- Fix cells with formaldehyde/glutaraldehyde solution.

- Incubate with X-gal solution at pH 6.0 overnight at 37°C (non-CO₂ incubator).

- Counterstain and quantify percentage of blue-stained senescent cells.

- Interpretation: Higher percentage of SA-β-gal positive cells indicates increased senescence, typically associated with older donors or extended in vitro culture [20].

Potency and Differentiation Assays

Protocol: Trilineage Differentiation Potential

- Objective: Verify multipotency of donor MSCs per ISCT criteria [20] [22].

- Osteogenic Differentiation:

- Adipogenic Differentiation:

- Culture MSCs in adipogenic induction media with dexamethasone, indomethacin, and IBMX.

- Visualize lipid vacuoles with Oil Red O staining after 2-3 weeks [20].

- Chondrogenic Differentiation:

- Pellet culture in chondrogenic media with TGF-β for 3-4 weeks.

- Analyze proteoglycan deposition with Safranin O or Alcian Blue staining [20].

Protocol: Colony-Forming Unit (CFU) Assay

- Objective: Assess clonogenic potential of donor MSCs [4] [23].

- Methodology:

- Interpretation: Higher CFU efficiency indicates greater clonogenic potential, characteristic of more potent MSCs from optimal donors [23].

Immunophenotyping

Protocol: Flow Cytometry Analysis

- Objective: Verify MSC surface marker expression profile [20] [4].

- Methodology:

- Harvest and wash MSC populations.

- Incubate with fluorochrome-conjugated antibodies against positive (CD73, CD90, CD105) and negative (CD34, CD45, HLA-DR) markers.

- Analyze using flow cytometry with appropriate isotype controls.

- Define population purity as percentage of CD45-/CD73+/CD90+/CD105+ cells [4].

- GMP Considerations: Use validated antibody panels and standardized operating procedures to ensure reproducibility [4] [22].

Research Reagent Solutions for Donor Evaluation

Table 4: Essential Reagents for GMP-Compliant MSC Donor Characterization

| Reagent Category | Specific Examples | Function | GMP Compliance |

|---|---|---|---|

| Cell Culture Media | MSC-Brew GMP Medium; MesenCult-ACF Plus Medium | Supports MSC expansion and maintenance | Xenogeneic-free, chemically defined [4] |

| Dissociation Reagents | Liberase; 0.1% Collagenase | Tissue digestion and cell harvesting | GMP-grade enzymes with certificate of analysis [20] [4] |

| Characterization Antibodies | BD Stemflow Human MSC Analysis Kit | Immunophenotyping by flow cytometry | Validated for clinical use [4] |

| Differentiation Kits | Osteogenic/Adipogenic/Chondrogenic Differentiation Media | Functional potency assessment | Defined compositions, lot-to-lot consistency [20] |

| Cryopreservation Media | DMSO-free cryoprotectants | Long-term cell storage | Xenogeneic-free, chemically defined [21] |

Donor selection represents a critical determinant in the feasibility of isolating clinically relevant MSCs under GMP standards. Chronological age significantly impacts proliferation capacity and differentiation potential, with younger donors generally providing more robust cells, though the relationship is complex and influenced by additional factors including biological source, sex, and genetic background. Comprehensive health status evaluation and rigorous infectious disease screening are essential for ensuring product safety. These biological considerations must be integrated within a robust ethical and regulatory framework that prioritizes informed consent, donor welfare, and transparency.

As the field advances, developing more predictive biomarkers of MSC potency and functionality will enhance donor selection protocols beyond chronological age and standard markers. The implementation of standardized, GMP-compliant workflows for donor evaluation—incorporating the experimental protocols and reagent systems outlined in this guide—will be essential for producing consistent, high-quality MSC therapies that fulfill their promising clinical potential while maintaining the highest ethical standards.

From Tissue to Vial: Step-by-Step GMP Isolation and Expansion Protocols

The translation of Mesenchymal Stem Cell (MSC) therapies from research to clinical application hinges on the development of robust, reproducible, and standardized isolation protocols that comply with Good Manufacturing Practice (GMP). The isolation method serves as the foundational step in manufacturing, directly influencing cell yield, purity, potency, and ultimately, the safety and efficacy of the final therapeutic product [3] [28]. Within this framework, two primary techniques—enzymatic digestion and explant culture—have emerged as the standard approaches for isolating MSCs from various tissues. The choice between these methods is critical for GMP-compliant production, as it affects process scalability, consistency, and the defined Critical Quality Attributes (CQAs) of the cell product [15] [28]. This technical guide provides an in-depth analysis of both techniques, comparing their parameters, outcomes, and applications within a GMP feasibility context to inform researchers and drug development professionals.

Core Technique Principles and Comparative Analysis

Enzymatic Digestion Method

The enzymatic digestion method utilizes specific enzymes, most commonly collagenases, to chemically degrade the extracellular matrix of tissue samples, thereby liberating individual cells for culture [15] [9]. This process involves tissue mincing, enzymatic dissociation, neutralization of the enzyme, and subsequent centrifugation to collect the cell pellet for seeding.

Optimized parameters for GMP-compliant enzymatic digestion, particularly for Wharton's jelly-derived MSCs (WJ-MSCs), have been established. Key findings indicate that a concentration of 0.4 PZ U/mL of a GMP-grade collagenase (e.g., Collagenase NB6) with a digestion time of 3 hours at 37°C yields the highest number of viable P0 cells [15]. The process must use enzymes that are GMP-compliant to mitigate risks associated with animal-derived components.

Explant Method

The explant method is a mechanical approach that relies on the migratory capacity of MSCs from tissue fragments. The process involves mincing the source tissue into small fragments (typically 1–4 mm^3), placing them directly onto culture vessel surfaces, and allowing cells to migrate out from the tissue explant to adhere to the plastic substrate [15] [9]. This method is generally considered simpler and minimizes exposure to external factors like enzymes, potentially better preserving cell viability and functionality [15].

Quantitative Comparison of Method Outcomes

The choice between isolation methods significantly impacts initial cell yield, outgrowth timing, and subsequent cell characteristics. The following table summarizes a direct comparative analysis based on validation studies.

Table 1: Quantitative Comparison of Enzymatic Digestion vs. Explant Isolation Methods

| Parameter | Enzymatic Digestion | Explant Method | GMP Feasibility Implications |

|---|---|---|---|

| Initial Cell Yield (P0) | Higher yield at optimal concentration (0.4 PZ U/mL) [15] | Lower initial yield [15] | Digestion supports larger batch sizes; critical for allogeneic therapies. |

| Time to Primary Culture | Faster outgrowth of first cells [15] | Slower initial outgrowth [15] | Digestion can reduce production timeline for P0. |

| Process Complexity | Higher complexity; requires enzyme optimization, inactivation, and removal [15] | Lower complexity; fewer steps and variables [15] | Explant may offer simpler validation but requires control of fragment size/distribution. |

| Risk of Cell Damage | Potential risk if enzymatic parameters are sub-optimal [15] | Minimizes enzymatic stress on cells [15] | Explant may enhance initial viability; digestion requires rigorous parameter control. |

| Post-Passage Characteristics | No significant differences in viability, morphology, proliferation, surface marker expression, or differentiation capacity after passaging [15] | No significant differences in viability, morphology, proliferation, surface marker expression, or differentiation capacity after passaging [15] | Choice of method for P0 may not affect the final cell product characteristics post-expansion. |

Detailed Experimental Protocols for GMP-Compliant Isolation

GMP-Compliant Enzymatic Digestion Protocol for Umbilical Cord

This protocol is adapted from a 2024 study establishing a GMP-compliant manufacturing method for Wharton's jelly-derived MSCs [15].

Tissue Pre-processing:

- Collection & Transport: Obtain umbilical cord tissue following ethical guidelines and informed consent. Transport in a sterile container at 2-10°C within 24 hours of collection [15].

- Decontamination & Dissection: Rinse the cord with DPBS without Ca2+/Mg2+. Decontaminate using a 0.5% povidone-iodine solution for 3 minutes, followed by three thorough rinses in DPBS to remove residual disinfectant and blood [15].

- Vessel Removal & Mincing: Dissect the cord to expose Wharton's jelly. Carefully remove two arteries and one vein. Mince the remaining Wharton's jelly tissue into fragments of 1–4 mm^3 [15].

Enzymatic Digestion:

- Digestion Reaction: Incubate the minced tissue fragments with a GMP-grade collagenase solution at a concentration of 0.4 PZ U/mL in a shaking incubator at 37°C for 3 hours [15].

- Reaction Termination & Filtration: Neutralize the enzyme by adding a volume of culture medium containing serum or human platelet lysate (hPL). Filter the resulting cell suspension through a 100 µm cell strainer to remove undigested tissue fragments and debris [3].

- Cell Pellet Collection: Centrifuge the filtrate at 300–400 × g for 10 minutes. Carefully aspirate the supernatant and resuspend the cell pellet in an appropriate animal component-free expansion medium, such as MSC-Brew GMP Medium or NutriStem supplemented with 2-5% hPL [3] [15].

Standardized Explant Culture Protocol

Tissue Pre-processing:

- Steps 1-3: Follow the identical tissue collection, decontamination, dissection, and mincing steps as described in the enzymatic digestion protocol [15] [9].

Explant Seeding and Culture:

- Fragment Seeding: Evenly distribute the pre-weighed, minced tissue fragments directly onto the surface of a culture-treated flask (e.g., 1 g of tissue per 75 cm² flask). Allow fragments to adhere to the plastic for a brief period (e.g., 15-30 minutes) in a small volume of medium to prevent them from floating [15] [9].

- Initial Culture: Carefully add a sufficient volume of pre-warmed, animal component-free culture medium to the flask without dislodging the fragments. Incubate the culture at 37°C, 5% CO2 [15].

- Medium Exchange and Monitoring: Perform a partial medium exchange every 2-3 days, taking care not to disturb the adherent explants. Monitor the cultures microscopically for the outgrowth of fibroblast-like, adherent MSCs, which typically begins within 5-14 days [15] [9].

- First Passage (P0): Once the outgrown cells reach 70–80% confluence, remove the original tissue fragments and detach the cells using a GMP-compliant dissociation reagent for subsequent expansion and passage [9].

Workflow Visualization of GMP Isolation Pathways

The following diagram illustrates the key decision points and parallel workflows for the two isolation methods within a GMP-compliant framework.

The Scientist's Toolkit: Essential Reagents for GMP-Compliant Isolation

The transition to clinical-grade manufacturing necessitates using GMP-compliant, xeno-free reagents. The following table details key solutions for MSC isolation and initial culture.

Table 2: Research Reagent Solutions for GMP-Compliant MSC Isolation

| Reagent / Material | Function / Purpose | GMP-Compliant Examples / Specifications |

|---|---|---|

| Collagenase NB6 GMP | Enzymatic digestion of collagen in the extracellular matrix to release cells. | GMP-grade enzyme with defined PZ U/mL activity; recommended concentration: 0.4 PZ U/mL [15]. |

| Animal Component-Free Media | Supports cell growth and expansion without animal-derived components, reducing contamination risk. | MSC-Brew GMP Medium, NutriStem, MesenCult-ACF Plus Medium [3] [15] [10]. |

| Human Platelet Lysate (hPL) | Serum substitute providing growth factors and attachment factors; enhances proliferation. | GMP-compliant, pathogen-inactivated. Effective at 2% or 5% concentration [15]. |

| DPBS (without Ca2+, Mg2+) | Washing and dilution buffer; absence of divalent cations is crucial for enzymatic digestion. | Must be sterile and endotoxin-free [15]. |

| Povidone-Iodine Solution (0.5%) | Tissue decontamination to minimize microbial load from the source tissue. | Used for a defined contact time (e.g., 3 minutes) followed by thorough rinsing [15]. |

| Cell Strainers (100 µm) | Removal of undigested tissue clumps and debris post-digestion to obtain a single-cell suspension. | Sterile, non-pyrogenic [3]. |

The feasibility of mesenchymal stem cell isolation under GMP research is critically dependent on a scientifically justified and well-controlled isolation process. Both enzymatic digestion and explant methods can yield MSCs that meet the ISCT's minimal criteria for identity, provided they are followed by standardized expansion and quality control procedures [15] [9]. The decision matrix for selecting a method should be based on the specific requirements of the therapeutic development program:

- Select Enzymatic Digestion when: The primary objective is to maximize the initial yield (P0) from a valuable tissue sample, the production process can accommodate higher complexity and tighter parameter control, and the timeline for generating P0 cells is a critical factor [15].

- Select Explant Culture when: The priority is to minimize process complexity and potential stressors on cells during initial isolation, the available infrastructure favors simpler, more contained processes, and a slightly longer time to primary culture is acceptable [15].

Ultimately, the chosen protocol must be thoroughly optimized, validated, and documented within a Quality Management System. This ensures process robustness, lot-to-lot consistency, and the production of a safe, high-quality MSC-based investigational medicinal product for clinical trials [3] [28].

The Shift to GMP-Compliant, Xenogeneic-Free Culture Media

The field of regenerative medicine is undergoing a critical transformation, moving from research-grade tools toward standardized, clinically compliant production systems. This shift is particularly evident in the culture of Mesenchymal Stem Cells (MSCs), which are a cornerstone of cell-based therapies for their immunomodulatory and regenerative properties [10]. The traditional use of fetal bovine serum (FBS) in cell culture media presents significant barriers to clinical translation, including risks of xenogeneic immune responses, batch-to-batch variability, and potential contamination with adventitious agents [10] [29]. These challenges have catalyzed the move toward xenogeneic-free media formulations manufactured under Good Manufacturing Practice (GMP) guidelines. This transition is not merely a technical improvement but a fundamental requirement for ensuring the safety, efficacy, and consistent quality of MSC-based therapies destined for human clinical applications [30]. This guide examines the feasibility of isolating and expanding MSCs under these stringent new conditions, providing researchers with the technical insights needed to navigate this essential shift.

GMP and Xenogeneic-Free Media: Definitions and Significance

What Constitutes GMP-Compliant Cell Culture Media?

For cell culture media to be classified as "GMP-grade," it must be manufactured and controlled according to a comprehensive set of quality assurance principles. These guidelines ensure consistent production of high-quality pharmaceutical products and excipients while minimizing risks associated with contamination, errors, and deviations [30]. Key aspects of GMP compliance for cell culture media include:

- Quality Control and Testing: Rigorous testing for microbial contamination, endotoxin levels, pH, osmolality, and nutritional content, often following standards described in the European Pharmacopoeia [30].

- Documentation and Traceability: Comprehensive documentation of manufacturing processes, quality control procedures, and testing results, along with full traceability of all ingredients to their original sources [30].

- Validation and Qualification: Manufacturing processes must be validated, and equipment must be qualified to ensure they consistently produce media that meet predetermined specifications [30].

- Personnel and Training: Employees involved in production must be adequately trained in GMP principles and practices, forming the backbone of a compliant manufacturing environment [30].

The Critical Importance of Xenogeneic-Free Formulations

Xenogeneic-free media are specifically designed to eliminate animal-derived components, replacing them with fully defined human-derived or synthetic alternatives. This elimination addresses several critical challenges:

- Reduced Immunogenicity: Animal-derived components can introduce immunogenic non-human epitopes, such as N-glycolylneuraminic acid, which risk triggering immune responses in human recipients [31].

- Enhanced Safety Profile: Removing animal-derived components minimizes the risk of transmitting zoonotic pathogens or introducing unknown contaminants [10].

- Improved Batch-to-Batch Consistency: Chemically defined formulations offer greater reproducibility compared to biologically derived sera, which naturally vary between batches [10] [31].

Experimental Evidence: Comparing Media Performance in MSC Culture

Quantitative Assessment of MSC Growth and Functionality

Recent studies have provided compelling quantitative data demonstrating the efficacy of GMP-compliant, xenogeneic-free media for MSC culture. The following table summarizes key findings from a 2025 study investigating infrapatellar fat pad-derived MSCs (FPMSCs):

Table 1: Performance Comparison of FPMSCs Cultured in Different Media Formulations [10]

| Parameter Assessed | Standard MSC Media (with FBS) | MesenCult-ACF Plus Medium | MSC-Brew GMP Medium |

|---|---|---|---|

| Doubling Time | Baseline (reference) | Lower than standard media | Lowest across passages |

| Colony Forming Unit (CFU) Capacity | Baseline (reference) | Higher than standard media | Highest observed |

| Post-Thaw Viability | Not specified | Not specified | >95% (up to 180 days of storage) |

| Sterility and Endotoxin | Not specified | Not specified | Meets all release specifications |

This study demonstrated that FPMSCs exhibited enhanced proliferation rates when cultured in MSC-Brew GMP Medium, as evidenced by lower doubling times across passages. Furthermore, a higher colony formation capacity indicated enhanced potency, a critical attribute for therapeutic efficacy [10].

Successful GMP-Validation and Long-Term Stability

The transition to GMP-compliance extends beyond media formulation to encompass the entire cell manufacturing process. Validation studies involving MSCs from four different donors confirmed that GMP-compliant protocols yielded cells that maintained stem cell marker expression and met all product release specifications [10]. Notably, these GMP-FPMSCs maintained viability exceeding 95% even after extended cryostorage (up to 180 days), demonstrating both the robustness of the isolation protocol and the stability of the final cell product [10]. This long-term stability is essential for creating off-the-shelf allogeneic MSC therapies.

Detailed Methodologies: Isolation and Culture Under GMP Conditions

Protocol: GMP-Compliant Isolation and Expansion of FPMSCs

The following workflow details a validated method for isolating and expanding MSCs in a GMP-compliant, xenogeneic-free system [10]:

Protocol: Assessment of Critical Quality Attributes

To ensure cells manufactured under GMP conditions meet release criteria, the following quality control assessments must be performed:

- Cell Doubling Time Calculation: Cells are seeded at a density of 5 × 10³ cells/cm² and grown to 80-90% confluency over multiple passages. Doubling time is calculated using the formula: Doubling Time = (Duration of Culture × Log2) / (Log Final Cell Count - Log Initial Cell Count) [10].

- Colony Forming Unit (CFU) Assay: Cells are seeded at low densities (20, 50, 100, and 500 cells per dish) and cultured for 10 days. Colonies are then fixed with formalin, stained with Crystal Violet, and counted to assess clonogenic potential, a key indicator of stem cell potency [10].

- Immunophenotyping by Flow Cytometry: Cells are harvested and stained using a validated panel of antibodies against MSC surface markers (e.g., CD73, CD90, CD105, with absence of hematopoietic markers). Analysis is performed using a flow cytometer with appropriate gating strategies to confirm MSC identity and purity [10] [9].

Essential Reagents for GMP-Compliant MSC Research

Transitioning to GMP-compliant workflows requires careful selection of every reagent. The table below catalogues key solutions for establishing a xenogeneic-free MSC research platform.

Table 2: Research Reagent Solutions for GMP-Compliant, Xenogeneic-Free MSC Culture

| Reagent / Material | Function / Purpose | Example Product / Alternative |

|---|---|---|

| GMP-Compliant Basal Media | Provides essential nutrients and buffer system for cell growth. | MSC-Brew GMP Medium [10], MesenCult-ACF Plus Medium [10], PromoExQ Media [30] [32] |

| Xenogeneic-Free Supplement | Supplements basal media with growth factors and adhesion proteins. | Human Platelet Lysate (hPL) [33], Human AB Serum [29] [34] |

| GMP-Grade Enzymes | For tissue dissociation and cell passaging; non-animal derived. | Recombinant Trypsin, Collagenase (GMP-grade) [10] |

| Cell Culture Substrates | Functionalized surface to support cell attachment and growth. | XF-DISC (functional polymer-coated substrates) [31] |

| Characterization Kits | Validated kits for immunophenotyping per ISCT guidelines. | BD Stemflow Human MSC Analysis Kit [10] |

The collective evidence confirms that the isolation and expansion of MSCs under GMP-compliant, xenogeneic-free conditions is not only feasible but also advantageous for clinical translation. Studies consistently show that MSCs cultured in advanced GMP media can demonstrate superior proliferative capacity, enhanced potency, and excellent post-preservation viability compared to those maintained in traditional FBS-containing systems [10] [33]. The availability of rigorously tested, GMP-grade reagents and standardized protocols provides researchers with the necessary toolkit to overcome the historical challenges of batch variability and safety concerns. As the field advances, the adoption of these standardized systems will be paramount for generating reproducible, safe, and effective MSC-based therapies, ultimately fulfilling their promise in regenerative medicine.

The transition of Mesenchymal Stem Cell (MSC) therapies from research to clinical application hinges on the establishment of robust, reproducible, and standardized manufacturing processes compliant with Good Manufacturing Practice (GMP). Central to this endeavor is the optimization of critical process parameters, primarily seeding density and population doubling time, which fundamentally determine the quality, efficacy, and safety of the final cell product [21]. These parameters are not merely indicators of growth; they are pivotal determinants of MSC stemness, functionality, and therapeutic potency [35]. The inherent heterogeneity of MSC cultures, influenced by donor variability and tissue source, necessitates a rigorously controlled manufacturing process to ensure a consistent and reliable product [21]. This guide details the experimental approaches and technical considerations for optimizing these parameters within a GMP framework, providing a foundation for the feasible isolation and expansion of MSCs for translational research.

Seeding Density: A Critical Determinant of MSC Quality and Homogeneity

The Impact of Seeding Density on Colony Formation and Cell Fitness

Seeding density, defined as the number of cells initially plated per unit area of culture surface, directly influences the clonogenic potential, proliferative capacity, and ultimate purity of the MSC population. Optimizing this parameter is essential for selecting for specific subpopulations with enhanced therapeutic potential.

A seminal study investigating the seeding density of bone marrow mononuclear cells (MNCs) revealed that lower densities (e.g., (1.25 \times 10^5) cells/cm²) foster the development of distinct colonies from single progenitor cells [36]. This low-density culture allows for the proportional expansion of highly proliferative MSCs over time, while faster-enlarging, less proliferative cells can be selectively removed through adjusted detachment protocols, thereby increasing the purity of the final product [36]. In contrast, high seeding densities ((1.25 \times 10^6) cells/cm²) lead to rapid confluence and do not favor this selective enrichment, resulting in MSCs with inferior proliferative and differentiation potential [36].

For the expansion of already-isolated MSCs, a seeding density of approximately 5,000 cells/cm² is widely recommended to balance efficient proliferation with the maintenance of stemness characteristics [37]. This density provides adequate space and resources for cell division while preventing the negative effects of overcrowding, such as nutrient depletion and accelerated differentiation.

Table 1: Impact of Mononuclear Cell (MNC) Seeding Density on MSC Isolation Outcomes

| Seeding Density (cells/cm²) | Colony Formation Characteristics | Proliferative Potential of Resulting MSCs | Differentiation Potential |

|---|---|---|---|

| Low ((1.25 \times 10^5)) | Distinct, well-separated colonies [36] | Significantly higher [36] | Enhanced adipogenic and chondrogenic potential [36] |

| High ((1.25 \times 10^6)) | Rapid, confluent growth; no distinct colonies [36] | Lower [36] | Reduced (except possibly osteogenic) [36] |

Experimental Protocol: Optimizing and Assessing Seeding Density

Objective: To determine the optimal seeding density of MNCs or passage MSCs for maximizing the yield and quality of MSCs.

Materials:

- Source of MSCs (e.g., bone marrow aspirate, infrapatellar fat pad tissue)

- GMP-compliant, animal component-free culture medium (e.g., MSC-Brew GMP Medium [10])

- Culture vessels (tissue-culture treated)

- Phosphate-Buffered Saline (PBS)

- GMP-compliant detachment agent (e.g., TrypLE Select [36])

- Hemacytometer or automated cell counter

- Crystal Violet stain (for colony-forming assays)

Method:

- Cell Isolation: Isolate MNCs from tissue using a GMP-compliant protocol, such as collagenase digestion followed by centrifugation and filtration [10].

- Experimental Seeding: Seed the isolated MNCs at a range of densities (e.g., (4.0 \times 10^4), (1.25 \times 10^5), (2.5 \times 10^5), (6.0 \times 10^5), (1.25 \times 10^6) cells/cm²) in culture vessels [36]. For passaging established MSCs, test densities around 5,000 cells/cm².

- Culture Maintenance: Culture cells in a standardized, animal component-free medium. Change the medium every 48-72 hours [37].

- Data Collection and Analysis:

- Colony Formation Unit (CFU) Assay: After ~10-14 days, fix cells with formalin and stain with Crystal Violet. Manually count the number of colonies formed [10] [36]. High-quality isolates are characterized by a high number of CFUs.

- Cell Morphology: Use time-lapse imaging to monitor colony formation and cell morphology daily [36].

- Flow Cytometry: At passage 3, analyze cells for standard MSC positive (CD73, CD90, CD105) and negative (CD34, CD45) surface markers to confirm identity and purity [10] [38].

- Proliferation Assays: Use population doubling time calculations and assays for markers like Ki67 and PCNA to assess growth rates [36].

Population Doubling Time: A Key Metric for MSC Expansion and Stemness

Understanding Doubling Time and Its Implications

Population doubling time (PDT) is a critical measure of the average time required for a cell population to double in number during the exponential growth phase. It serves as a vital indicator of MSC fitness, proliferative capacity, and biological age. A lower, consistent doubling time is indicative of healthy, stemness-retaining cells, while an increasing PDT is a hallmark of cellular senescence and reduced therapeutic potency [35] [39].

The PDT is profoundly influenced by several factors, including the culture medium formulation, donor age, and passage number. For instance, MSCs cultured in optimized, GMP-compliant media like MSC-Brew GMP Medium have demonstrated significantly lower doubling times compared to those in standard media, underscoring the impact of media composition on growth kinetics [10]. Furthermore, PDT tends to increase with successive passages, reflecting the gradual senescence of the culture [38] [39].

Table 2: Impact of Culture Conditions on Mesenchymal Stem Cell Doubling Time

| Culture Condition | Reported Doubling Time | Context and Implications |

|---|---|---|