Herbal Medicine Standardization: Advanced Methods for Quality Control and Evidence-Based Research

This article provides a comprehensive overview of contemporary standardization methods for herbal medicine preparations, tailored for researchers, scientists, and drug development professionals.

Herbal Medicine Standardization: Advanced Methods for Quality Control and Evidence-Based Research

Abstract

This article provides a comprehensive overview of contemporary standardization methods for herbal medicine preparations, tailored for researchers, scientists, and drug development professionals. It explores the foundational necessity of quality control for ensuring safety and efficacy, details advanced methodological approaches from pharmacognosy to modern analytics, addresses key challenges in research and regulation, and evaluates validation frameworks and comparative regulatory landscapes. By synthesizing traditional knowledge with cutting-edge scientific rigor, this review aims to bridge the gap between herbal medicine and mainstream pharmaceutical development, promoting reproducible, high-quality, and evidence-based herbal products.

The Critical Need for Standardization in Modern Herbal Medicine

Troubleshooting Guides

Inconsistent Bioactive Compound Levels Between Batches

Problem: High batch-to-batch variability in the concentration of key active compounds or markers, leading to unreliable therapeutic outcomes [1].

Solution:

- Root Cause: Lack of robust standardization protocols for raw materials and extraction processes.

- Corrective Action: Implement a comprehensive standardization workflow for herbal materials.

- Step 1: Authentication: Use macroscopic, microscopic, and DNA barcoding to verify the correct botanical species and plant part [1] [2].

- Step 2: Quantitative Analysis: Employ chromatographic techniques (HPLC, TLC, GC) to quantify levels of active compounds or marker compounds [1] [3].

- Step 3: Establish Reference Standards: Use certified reference materials as benchmarks for quality control testing to ensure consistency across production batches [1].

- Step 4: Process Validation: Standardize and validate the extraction methodology to ensure reliable and reproducible extraction of bioactive constituents [2].

Contamination and Adulteration

Problem: Herbal products test positive for contaminants such as heavy metals, pesticides, or microbial organisms, or are adulterated with undeclared, potentially harmful substances [1].

Solution:

- Root Cause: Inadequate quality control testing and insufficient supply chain traceability.

- Corrective Action: Enforce stringent quality assurance testing and documentation.

- Step 1: Implement Testing Protocols: Conduct rigorous physicochemical and microbiological testing on all incoming raw materials and final products [2].

- Step 2: Detect Contaminants: Use modern analytical techniques like ICP-MS for heavy metal testing and chromatography for pesticide residue analysis [2].

- Step 3: Adulteration Screening: Apply spectroscopic methods and chemical marker analysis to detect and prevent the presence of non-declared substances or synthetic dyes [2].

- Step 4: Ensure Traceability: Maintain detailed Batch Manufacturing Records (BMRs) that document the source and movement of all material inputs within the supply chain [2].

Lack of Reproducible Efficacy in Preclinical/Clinical Studies

Problem: Herbal preparations demonstrate variable therapeutic effects in research settings, making it difficult to obtain reproducible and reliable data [1].

Solution:

- Root Cause: Failure to account for multiple sources of variation, including herb quality, patient/disease factors, and preparation methods.

- Corrective Action: Adopt a multivariable optimization framework in study design [4].

- Step 1: Control Herb Variation: Through quality optimization and rigorous herbal drug development protocols as detailed in sections 1.1 and 1.2 [4].

- Step 2: Account for Disease Variation: Integrate traditional diagnostic criteria and ensure research practitioners are thoroughly trained in the specific traditional context of the herbal medicine [4].

- Step 3: Address Patient Variation: Incorporate personalized medicine principles by considering factors such as genetics, metabolism, and individual health status when designing trials and interpreting results [4].

Frequently Asked Questions (FAQs)

Q1: What is the fundamental definition of "standardization" in the context of herbal medicine research?

Standardization is a systematic process of defining and maintaining consistent levels of active compounds or marker compounds in herbal medication products [1]. It involves establishing and adhering to predetermined quality specifications to minimize batch-to-batch variability, ensuring the product is reproducible, safe, and possesses consistent pharmacological activity [1] [3]. This is distinct from merely identifying plants; it focuses on chemical and biological consistency.

Q2: Which analytical techniques are considered essential for the standardization of herbal drugs?

A combination of techniques is required to comprehensively assess the quality of an herbal drug. The following table summarizes the key methods and their primary applications in standardization.

| Technique | Primary Application in Standardization | Brief Description |

|---|---|---|

| Chromatographic Fingerprinting (HPLC, TLC) [1] [2] | Identity confirmation & quantification of active/marker compounds. | Creates a unique chemical "profile" of the herb for identification and quantitation. |

| DNA Barcoding [1] [2] | Authentication of botanical species. | Uses a short genetic marker to identify the plant species and detect adulteration. |

| Spectroscopy (UV-Vis, IR, NMR) [1] | Quantitative analysis and structural elucidation. | Measures the interaction of light with matter to determine concentration or identify compounds. |

| ICP-MS / AAS [2] | Heavy metal testing. | Precisely detects and quantifies toxic heavy metal residues (e.g., arsenic, lead). |

Q3: What are the critical quality control parameters for herbal manufacturers, and how are they tested?

According to WHO and good manufacturing practices (GMP), critical parameters ensure safety, purity, and consistency. The tests must be performed on raw materials, in-process materials, and the final product [2].

| Quality Parameter | Purpose | Common Tests/Techniques |

|---|---|---|

| Physicochemical Testing [2] | Assess product consistency and chemical properties. | pH, viscosity, solubility, HPLC, TLC. |

| Microbiological Testing [2] | Ensure absence of harmful microorganisms. | Total viable aerobic count, tests for yeast/mold, E. coli, Salmonella. |

| Heavy Metal & Pesticide Limits [2] | Verify compliance with safety limits for toxic residues. | ICP-MS, AAS, chromatography for pesticide residue. |

| Adulteration & Contaminants [2] | Detect and prevent presence of non-declared or harmful substances. | Visual inspection, spectroscopy, chemical marker analysis. |

Q4: How do regulatory frameworks for herbal medicines differ from those for conventional pharmaceutical drugs?

The regulatory framework for herbal products differs starkly from that of prescription drugs. In many regions, including the U.S. under the DSHEA Act of 1994, herbal products do not require prior regulatory approval (e.g., from the FDA) for safety or effectiveness before being marketed [5]. Unlike conventional drugs, which undergo stringent pre-market testing for potency and safety, herbal supplements are often regulated as dietary supplements, placing more emphasis on post-market surveillance and adherence to Good Manufacturing Practices (cGMP) [5] [3]. This fundamental difference underscores the critical need for rigorous self-regulation and quality control within the herbal research and manufacturing industries.

Q5: What is a multivariable optimization framework in herbal medicine research?

A multivariable optimization framework is a modern approach designed to overcome the limitations of traditional single-variable standardization. It simultaneously controls for the three main sources of variability that compromise herbal therapy outcomes:

- Herb Variation: Addressed through quality optimization (e.g., GAP, GMP) and advanced analytical methods [4].

- Disease Variation: Managed by integrating traditional knowledge and training practitioners in specific diagnostic criteria [4].

- Patient Variation: Addressed by tailoring treatments using personalized medicine principles, potentially leveraging multi-omics tools [4]. This framework aims to enhance treatment reliability and safety over conventional methods and facilitate the integration of herbal medicine into modern evidence-based healthcare [4].

Experimental Protocols & Workflows

Protocol: Standardization of Raw Herbal Material

Objective: To authenticate the plant material and establish a chemical fingerprint for quality control.

Materials:

- Herbal raw material (e.g., dried root, leaf)

- Solvents (e.g., methanol, ethanol, water)

- Reference standards for marker compounds

- TLC plates or HPLC columns

- DNA extraction and amplification kits

Methodology:

- Authentication:

- Chromatographic Fingerprinting:

- Sample Preparation: Prepare a representative extract of the herbal material using a standardized solvent and method [1].

- Analysis: Inject the sample into an HPLC or apply to a TLC plate alongside reference standards.

- Data Interpretation: Generate a chromatogram or TLC profile. Identify the marker compounds by comparing retention times/Rf values with standards. Use this fingerprint as a benchmark for future batches [1] [2].

Workflow: Quality Control for Herbal Drug Development

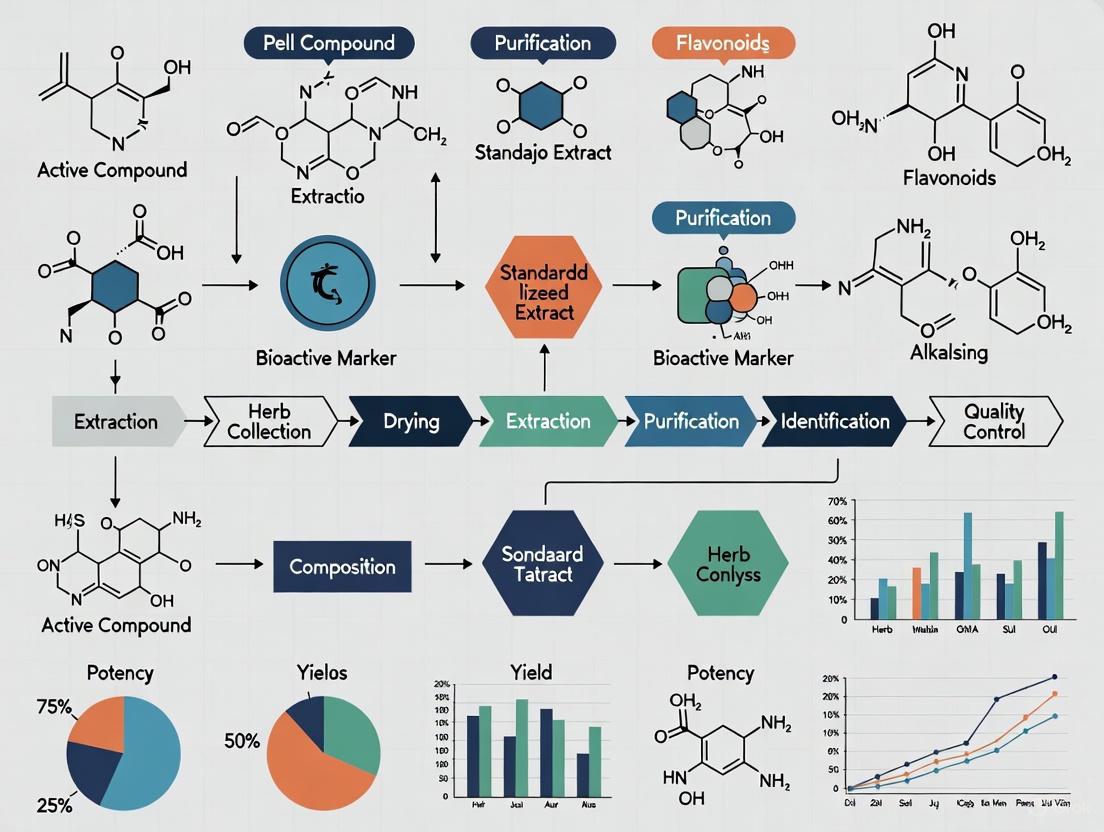

The following diagram illustrates the logical workflow for ensuring quality throughout the herbal drug development process, integrating key steps from authentication to final product release.

The Scientist's Toolkit: Key Research Reagent Solutions

The following table details essential materials and reagents used in the standardization and quality control of herbal preparations.

| Item | Function/Explanation |

|---|---|

| Certified Reference Standards [1] | Pure, well-characterized chemical compounds used as benchmarks in analytical methods (e.g., HPLC, TLC) to identify and quantify active or marker compounds in herbal samples. |

| DNA Barcoding Kits [1] [2] | Kits containing reagents for DNA extraction, purification, PCR amplification, and sequencing of standard barcode regions (e.g., ITS, rbcL) to authenticate botanical species and detect adulteration. |

| Chromatography Consumables [1] [3] | Includes specific HPLC columns (e.g., C18), TLC plates, solvents, and mobile phases tailored for the separation and analysis of complex phytochemical mixtures in herbal extracts. |

| Stable Isotope-Labeled Internal Standards | Used in advanced mass spectrometry (e.g., LC-MS) for highly accurate and precise quantification of compounds, correcting for analyte loss during sample preparation and matrix effects. |

| Microbiological Culture Media [2] | Selective and non-selective media used in pharmacopoeial tests to determine the total viable aerobic microbial count and test for the absence of specified pathogens (e.g., E. coli, Salmonella). |

The Global Reliance on Herbal Medicine and Implications for Public Health

Herbal medicine represents a cornerstone of healthcare for a significant portion of the global population. The World Health Organization (WHO) reports that approximately 80% of the world's population relies on traditional medicine, a category predominantly comprised of herbal remedies, for primary healthcare needs [2]. This reliance is reflected in the market's robust growth, with the global medicinal herbs sector projected to increase from an estimated USD 227.65 billion in 2025 to USD 478.93 billion by 2032, exhibiting a compound annual growth rate (CAGR) of 11.21% [6]. This surge is largely driven by rising consumer preference for natural and organic healthcare solutions, particularly for chronic and lifestyle-related conditions [6].

The recent WHO Global Traditional Medicine Strategy (2025–2034), adopted at the 78th World Health Assembly, marks a pivotal milestone. This strategy aims to accelerate the integration of evidence-based Traditional, Complementary and Integrative Medicine (TCIM) into health systems worldwide, emphasizing the establishment of a robust evidence base, regulatory mechanisms for quality and safety, and the protection of Indigenous knowledge and rights [7] [8]. For researchers and drug development professionals, this global momentum underscores an urgent need for standardized, reproducible, and high-quality research methodologies to validate herbal medicine practices and products, ensuring their safety and efficacy for public health.

Technical Support & Troubleshooting Hub

This section addresses common experimental challenges in herbal medicine research, providing targeted solutions and methodologies to enhance the reliability and reproducibility of your findings.

Frequently Asked Questions (FAQs)

1. How can I resolve batch-to-batch variability in my herbal test material? Batch-to-batch inconsistency is a major challenge that can invalidate research outcomes. To address this:

- Standardize the Source: Begin with rigorous botanical authentication of raw materials using macroscopic, microscopic, and DNA barcoding techniques to ensure species and plant part correctness [1] [2].

- Establish Quality Parameters: Define and monitor key physicochemical parameters such as the content of active compounds or marker substances using HPLC or TLC. Implement chromatographic fingerprinting to create a unique chemical profile for consistency checks [1] [9].

- Control the Process: Adhere to standardized, validated extraction and manufacturing processes. Utilize Good Manufacturing Practices (GMP) to ensure every production step is controlled and documented, from raw material sourcing to final product packaging [2].

2. What are the best practices for authenticating herbal ingredients and detecting adulterants? Authentication and adulteration detection require a multi-faceted analytical approach:

- Hierarchical Analysis: Start with simple methods like macroscopic and microscopic examination, then progress to more complex techniques.

- Chromatographic Profiling: Techniques like Thin-Layer Chromatography (TLC) and High-Performance Liquid Chromatography (HPLC) are essential for comparing the chemical profile of your sample against a verified reference standard [1].

- Advanced Techniques: For high specificity, employ DNA barcoding for species-level genetic authentication. Use Mass Spectrometry (e.g., LC-MS) to detect and identify unexpected chemical compounds, such as synthetic drug adulterants or contaminants [1] [9].

3. My experimental results are inconsistent with historical or traditional use data. Why? Discrepancies between laboratory results and traditional knowledge can arise from several factors:

- Preparation Disparity: The laboratory extraction method (e.g., using a single solvent like methanol) may differ significantly from traditional preparation methods (e.g., decoctions in water), leading to different phytochemical profiles and bioactivity [9].

- Holistic vs. Reductionist Approach: Traditional medicine often uses polyherbal formulations where the therapeutic effect is synergistic. Isolating a single compound may not capture the full effect [10].

- Insufficient Quality Control: The test material used in your study may be adulterated, contaminated, or degraded, leading to results that do not reflect the authentic traditional medicine practice [1]. Re-evaluate the quality of your research material against the specifications of the traditional system you are studying.

4. How do I design a placebo for a clinical trial involving a distinctive-smelling or tasting herbal product? Creating a convincing placebo for herbal products is critical for maintaining blinding.

- Placebo Matching: Develop a placebo that matches the active product in every physical aspect—size, shape, color, and weight.

- Taste and Smell Masking: For distinctive organoleptic properties, use food-grade flavorings and odorants that mimic the herbal product. Inactive herb powders with similar characteristics can also be blended.

- Encapsulation: The most effective method is often to encapsulate both the active product and the placebo in opaque, size-matched capsules to minimize sensory differences [10]. A successful placebo should be indistinguishable from the verum in a blind test.

Experimental Protocols for Key Analyses

Protocol 1: Chromatographic Fingerprinting for Standardization

- Objective: To create a unique chemical profile for quality control and batch consistency of an herbal extract.

- Materials: Herbal test sample, reference standard (e.g., from a pharmacopoeia), HPLC system with UV/VIS or DAD detector, analytical column (C18), solvents (HPLC-grade water, acetonitrile, methanol), and filtration apparatus.

- Method:

- Sample Preparation: Accurately weigh a specified amount of herbal extract. Dissolve and dilute in an appropriate solvent. Filter through a 0.45 µm or 0.22 µm membrane filter.

- HPLC Conditions:

- Column: C18 (e.g., 250 mm x 4.6 mm, 5 µm)

- Mobile Phase: Gradient of solvent A (0.1% formic acid in water) and solvent B (acetonitrile).

- Flow Rate: 1.0 mL/min

- Detection: UV-Vis/DAD, typically at 254-280 nm (or a wavelength specific to the target compounds).

- Injection Volume: 10-20 µL

- Analysis: Inject the reference standard and the test sample. The fingerprint of the test sample should match the profile and relative retention times of the peaks in the reference standard fingerprint [1] [2].

Protocol 2: DNA Barcoding for Botanical Authentication

- Objective: To genetically identify the plant species in an herbal material to prevent misidentification and adulteration.

- Materials: Plant sample, DNA extraction kit, PCR thermal cycler, primers for standard barcode regions (e.g., matK, rbcL, ITS2), gel electrophoresis equipment, and sequencing facility access.

- Method:

- DNA Extraction: Isolate genomic DNA from the herbal material (fresh, dried, or powdered) using a commercial kit optimized for plants.

- PCR Amplification: Amplify the selected barcode region(s) using universal primers in a PCR reaction.

- Gel Electrophoresis: Confirm successful amplification by running the PCR product on an agarose gel.

- Sequencing and Analysis: Purify the PCR product and send it for Sanger sequencing. Compare the resulting DNA sequence to a curated reference database (e.g., GenBank, BOLD) for species identification [1] [2].

Table 1: Global Medicinal Herbs Market Overview (2025-2032 Projection)

| Metric | Value / Forecast | Notes / Source |

|---|---|---|

| Market Size (2025) | USD 227.65 Billion | [6] |

| Projected Market Size (2032) | USD 478.93 Billion | [6] |

| Compound Annual Growth Rate (CAGR) | 11.21% | Projected for 2025-2032 [6] |

| Top-Selling Herb Type (2025) | Ginseng | 16.6% market revenue share [6] |

| Dominant Application (2025) | Pharmaceuticals | Revenue ~USD 95.8 Billion [6] |

| Leading Regional Market (2025) | Asia-Pacific | >40% global revenue share [6] |

Table 2: Key Quality Control Parameters for Herbal Materials [1] [2]

| Parameter | Purpose | Common Analytical Methods |

|---|---|---|

| Physicochemical Testing | Assess product consistency and chemical properties | pH, viscosity, solubility, HPLC, TLC |

| Microbiological Testing | Ensure absence of harmful microorganisms | Total viable aerobic count, tests for yeast/mold, E. coli, Salmonella |

| Heavy Metal & Pesticide Limits | Verify compliance with safety limits for toxic residues | ICP-MS, AAS, Chromatography (GC-MS/LC-MS) |

| Adulteration & Contaminants | Detect non-declared or harmful substances | Visual inspection, spectroscopy, chemical marker analysis |

| Chromatographic Fingerprinting | Confirm identity and quantify active compounds | TLC, HPLC, HPTLC with reference marker compounds |

Research Workflow Visualization

Quality Control Workflow for Herbal Medicine Research

Herbal Ingredient Authentication Pathway

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 3: Key Research Reagent Solutions for Herbal Medicine Standardization

| Item | Function / Application |

|---|---|

| Reference Standards | Certified chemical compounds used to identify and quantify active markers or impurities in herbal samples via HPLC, GC, or TLC. Critical for method validation and standardization [1]. |

| DNA Extraction Kits | Optimized reagents for isolating high-quality genomic DNA from complex plant tissues, which is the first critical step for DNA barcoding and genetic authentication [1]. |

| PCR Primers (e.g., matK, rbcL) | Short, specific DNA sequences designed to amplify standard barcode regions for plant species identification and phylogenetic analysis [1]. |

| Chromatography Columns (C18) | The stationary phase in Reverse-Phase HPLC systems for separating complex mixtures of phytochemicals based on their hydrophobicity [1] [9]. |

| Mobile Phase Solvents | High-purity solvents (e.g., Acetonitrile, Methanol) and modifiers used as the liquid medium in HPLC to elute compounds from the column [1]. |

| Microbiological Culture Media | Used in microbial limit tests to detect and enumerate total viable aerobic count, yeast, and mold in herbal products to ensure safety [2]. |

Core Concepts: Understanding Quality Control Failures

What are the primary consequences of inadequate quality control in herbal medicine research?

Inadequate quality control in herbal medicine research leads to three primary consequences: variability in product composition, contamination with harmful substances, and adulteration with undeclared ingredients. These failures compromise experimental reproducibility, product safety, and therapeutic efficacy, ultimately undermining the validity and reliability of research findings [1] [9].

- Variability: Inconsistent levels of active compounds between batches creates significant challenges for reproducing experimental results and establishing reliable dose-response relationships [1]. This inconsistency stems from insufficient standardization of raw materials and manufacturing processes.

- Contaminants: Herbal products may contain biological (microbes, molds), chemical (pesticides, heavy metals), or physical (glass, metal) contaminants introduced during cultivation, processing, or storage [1] [11]. These pose direct safety risks to research subjects and consumers.

- Adulteration: The deliberate substitution or addition of undeclared substances, including synthetic drugs or inferior herbal species, constitutes adulteration [12]. This practice misrepresents the true nature of the test material and invalidates experimental conclusions.

How do these quality failures impact drug development timelines and costs?

Quality failures significantly increase drug development timelines and costs through multiple mechanisms:

- Preclinical Delays: Variable composition necessitates repeated experiments to verify biological activity, increasing animal studies and in vitro testing requirements.

- Clinical Setbacks: Contaminant discoveries during clinical trials can halt studies entirely, requiring investigation, protocol revisions, and regulatory resubmissions.

- Regulatory Rejection: Insufficient quality control data results in regulatory authority requests for additional information or complete rejection of marketing applications [2].

- Product Recalls: Marketed products requiring recall due to quality issues generate substantial financial losses and reputational damage [12].

Troubleshooting Guides

Problem: Inconsistent Bioactivity Between Batches

Problem Identification: Researchers observe significant variation in pharmacological activity between different batches of the same herbal extract despite using identical experimental protocols.

Root Cause Analysis:

- Source Variation: Differences in growing conditions, harvest time, or plant genetics affecting phytochemical profiles [1]

- Processing Inconsistency: Variable extraction parameters (temperature, solvent, time) or post-extraction handling

- Authentication Issues: Misidentification of plant species or use of incorrect plant parts

Resolution Protocol:

- Implement Chromatographic Fingerprinting: Develop HPLC or HPTLC fingerprints to establish a baseline chemical profile for reference batches [2] [9]

- Quantify Marker Compounds: Identify and quantify key active compounds or chemical markers to establish minimum potency thresholds [1]

- Standardize Extraction Procedures: Document and strictly control all extraction parameters including solvent composition, temperature, time, and particle size

- Validate Analytical Methods: Establish method precision, accuracy, and reproducibility following ICH guidelines [2]

Preventive Measures:

- Develop standardized operating procedures (SOPs) for all processing steps

- Establish quality specifications for raw materials including botanical identity and chemical composition

- Implement reference standard comparison for each new batch

Problem: Suspected Adulteration with Synthetic Compounds

Problem Identification: Unexpected pharmacological effects or analytical results suggest potential adulteration with synthetic pharmaceutical compounds.

Root Cause Analysis:

- Economic Motive: Deliberate adulteration to enhance perceived efficacy at lower cost [12]

- Supply Chain Complexity: Lack of transparency in multi-tier supplier networks

- Insufficient Screening: Inadequate analytical methods to detect non-botanical substances

Resolution Protocol:

- Comprehensive Screening: Employ LC-MS/MS to screen for common synthetic adulterants based on product claims

- Comparative Analysis: Compare chromatographic profiles with authenticated reference samples

- Forensic Investigation: Trace supply chain documentation to identify potential points of adulteration

- Bioactivity Assessment: Evaluate whether observed pharmacological effects align with expected herbal activity

Preventive Measures:

- Implement supplier verification programs with rigorous qualification criteria

- Conduct random testing of incoming raw materials using targeted and untargeted methods

- Establish chemical fingerprints for authenticated reference materials

Problem: Contamination with Heavy Metals or Pesticides

Problem Identification: Routine testing detects heavy metals or pesticide residues above acceptable thresholds in herbal test materials.

Root Cause Analysis:

- Environmental Factors: Contaminated soil or water from cultivation sites [1]

- Agricultural Practices: Use of banned or excessive pesticides during cultivation

- Processing Equipment: Leaching of metals from processing machinery or containers

Resolution Protocol:

- Source Identification: Use ICP-MS for heavy metal profiling and GC-MS for pesticide analysis to identify contaminants [2]

- Supplier Assessment: Audit cultivation practices and environmental conditions at source farms

- Purification Evaluation: Assess whether processing methods can reduce contaminants to acceptable levels

- Material Rejection: Establish rejection criteria for contaminated materials exceeding safety thresholds

Preventive Measures:

- Implement rigorous supplier qualification including environmental testing

- Establish certificate of analysis requirements with specific contaminant limits

- Conduct regular audits of cultivation and collection practices

Frequently Asked Questions (FAQs)

What are the minimum quality control parameters for herbal material in preclinical research?

For credible preclinical research, herbal materials should be characterized against these minimum parameters:

Table: Essential Quality Control Parameters for Herbal Research Materials

| Parameter | Purpose | Recommended Methods | Acceptance Criteria |

|---|---|---|---|

| Botanical Authentication | Verify correct species and plant part | Macroscopic/microscopy examination, DNA barcoding [1] | Match to authenticated voucher specimen |

| Chemical Fingerprinting | Establish chemical profile consistency | HPTLC, HPLC, GC [9] | Minimum 80% similarity to reference fingerprint |

| Marker Compound Quantification | Standardize potency | HPLC-UV, LC-MS [1] | ±15% of reference batch concentration |

| Contaminant Screening | Ensure material safety | ICP-MS (heavy metals), GC-MS (pesticides) [2] | Below ICH/USP regulatory limits |

| Microbial Limits | Prevent biological contamination | Total viable count, pathogen testing [2] | Meet pharmacopeial standards |

How can researchers authenticate herbal species when reference standards are unavailable?

When certified reference standards are unavailable, researchers can employ these authentication strategies:

- Comparative Morphology: Conduct macroscopic and microscopic examination against authoritative botanical descriptions [1]

- DNA Barcoding: Sequence specific genomic regions (e.g., ITS, rbcL) and compare to genomic databases [1] [2]

- Voucher Specimens: Deposit authenticated specimens in herbarium for future reference

- Chemical Profiling: Develop characteristic fingerprints using multiple analytical techniques

- Expert Verification: Consult botanical taxonomists for species identification

What analytical techniques are most suitable for detecting different types of adulteration?

Adulteration detection requires technique selection based on the nature of suspected adulterants:

Table: Analytical Techniques for Adulterant Detection

| Adulteration Type | Primary Techniques | Secondary Techniques | Detection Capability |

|---|---|---|---|

| Species Substitution | DNA barcoding [1], HPTLC [9] | Microscopy, HPLC fingerprinting | Genetic differences, chemical profile variances |

| Addition of Synthetic Drugs | LC-MS/MS, HPLC-DAD | GC-MS, NMR | Nanogram-level detection of pharmaceuticals |

| Undisclosed Fillers | FT-IR, NIR spectroscopy | Microscopy, chemical tests | Identification of starch, sugars, other diluents |

| Heavy Metal Contamination | ICP-MS, AAS [2] | XRF, ICP-OES | Parts-per-billion detection of toxic elements |

| Pesticide Residues | GC-MS/MS, LC-MS/MS | HPLC, ELISA | Multiple residue screening at regulatory limits |

Experimental Protocols

Protocol: Development of Chromatographic Fingerprints for Batch Standardization

Principle: Chromatographic fingerprinting provides a comprehensive profile of multiple constituents to ensure consistent chemical composition across research batches [9].

Materials and Equipment:

- Herbal test material (minimum 3 batches from different sources)

- Reference standard compounds (if available)

- HPLC/HPTLC system with photodiode array detector

- Analytical balance (±0.0001 g precision)

- Ultrasonic bath for extraction

- HPLC-grade solvents (methanol, acetonitrile, water)

- Chromatography columns/cellulose plates

Procedure:

- Sample Preparation: Precisely weigh 1.0 g powdered herb, extract with 10 mL methanol-water (70:30) via ultrasonication (30 min, 25°C)

- Centrifugation: Centrifuge at 10,000 rpm for 10 minutes, filter through 0.45 μm membrane

- Instrument Conditions:

- Column: C18 (250 × 4.6 mm, 5 μm)

- Mobile phase: Gradient of 0.1% formic acid (A) and acetonitrile (B)

- Flow rate: 1.0 mL/min

- Detection: 190-400 nm scanning

- Injection volume: 10 μL

- Analysis: Inject samples in triplicate, record chromatograms at multiple wavelengths

- Data Processing: Calculate relative retention times and peak areas of characteristic peaks

Validation Parameters:

- Precision (RSD < 2% for retention times)

- Stability (RSD < 3% over 24 hours)

- Reproducibility (RSD < 5% between instruments)

Interpretation: Fingerprints from test batches should show minimum 80% similarity to reference fingerprint when evaluated using chemometric software.

Protocol: Heavy Metal Analysis via ICP-MS

Principle: Inductively coupled plasma mass spectrometry provides sensitive multi-element detection for toxic heavy metals in herbal materials [2].

Materials and Equipment:

- ICP-MS instrument with collision/reaction cell

- Certified reference material (CRM) for quality control

- High-purity nitric acid (trace metal grade)

- Microwave digestion system

- Ultra-pure water (18.2 MΩ·cm)

- Single-element standard solutions (As, Cd, Pb, Hg)

Procedure:

- Sample Digestion: Accurately weigh 0.5 g powdered sample into digestion vessel, add 5 mL nitric acid

- Microwave Program:

- Step 1: Ramp to 100°C in 10 min, hold 5 min

- Step 2: Ramp to 180°C in 10 min, hold 15 min

- Cooling: 30 min to room temperature

- Dilution: Transfer digestate to 50 mL volumetric flask, dilute to volume with ultra-pure water

- Calibration: Prepare standard curve (0, 0.5, 1, 5, 10, 50 μg/L) for each element

- ICP-MS Analysis:

- RF power: 1550 W

- Carrier gas: 0.8 L/min argon

- Integration time: 0.5-1.0 s per mass

- Measured isotopes: 75As, 111Cd, 208Pb, 202Hg

Quality Control:

- Analyze method blank with each batch

- Include CRM every 10 samples (recovery 85-115%)

- Internal standard (e.g., 115In, 209Bi) for drift correction

Calculation: Element concentration (mg/kg) = (C × V × D) / W Where: C = concentration from calibration (μg/L), V = final volume (mL), D = dilution factor, W = sample weight (g)

Visualizations

Quality Control Failure Investigation Pathway

Herbal Material Authentication Workflow

The Scientist's Toolkit: Essential Research Reagents & Materials

Table: Essential Materials for Herbal Medicine Quality Control Research

| Category | Specific Items | Research Application | Quality Specifications |

|---|---|---|---|

| Reference Standards | Certified chemical markers, authenticated botanical specimens [1] | Method validation, compound identification | ≥95% purity, documented provenance |

| Chromatography Supplies | HPLC columns (C18, HILIC), HPTLC plates, GC capillaries [9] | Compound separation, fingerprint development | LC-MS grade solvents, certified columns |

| Molecular Biology Kits | DNA extraction kits, PCR master mixes, sequencing primers [1] | Genetic authentication, species identification | DNA-free components, high fidelity enzymes |

| Sample Preparation | Solid-phase extraction cartridges, filtration units, microwave digestion vessels | Sample clean-up, contaminant removal | Low extractable backgrounds, high recovery |

| Spectroscopy Supplies | ICP-MS calibration standards, AAS lamps, NMR solvents [2] | Elemental analysis, structural elucidation | Traceable standards, deuterated solvents |

| Microbiology Materials | Culture media, membrane filters, incubation equipment | Microbial limit testing, sterility verification | Sterility-certified, growth-promoting tested |

Bridging Traditional Knowledge and Modern Scientific Validation

Technical Support Center: FAQs & Troubleshooting Guides

Frequently Asked Questions (FAQs)

Q1: What constitutes a scientifically valid approach for documenting traditional herbal knowledge? A1: Valid documentation requires a structured ethnobotanical framework combining:

- Scientific Authentication: Proper botanical identification using macroscopic, microscopic, and molecular methods (e.g., DNA barcoding) to verify species and plant parts used [13] [2].

- Traditional Context Recording: Detailed documentation of traditional preparation methods, dosage forms, administration routes, and cultural protocols through interviews with knowledge holders [13] [14].

- Chemical Profiling: Initial phytochemical screening using chromatographic fingerprinting (TLC, HPLC) to identify marker compounds and potential bioactive constituents [4] [13].

Q2: How can researchers address batch-to-batch variability in herbal material? A2: Implement a multivariable optimization framework controlling three key domains [4]:

- Herb Variation: Standardize cultivation (Good Agricultural Practices), harvesting timing, and processing methods to minimize phytochemical fluctuations.

- Disease Variation: Develop clear diagnostic criteria and practitioner training for consistent application.

- Patient Variation: Incorporate personalized medicine principles considering individual patient factors and constitutions.

Q3: What are the essential quality control parameters for herbal medicine research? A3: The WHO outlines critical quality parameters that should be standardized [2]:

Table: Essential Quality Control Parameters for Herbal Research

| Parameter | Purpose | Standard Methods | Acceptance Criteria |

|---|---|---|---|

| Botanical Authentication | Verify plant species & part | Macroscopic/microscopic examination, DNA barcoding | Match reference standards |

| Physicochemical Properties | Assess consistency | pH, viscosity, solubility, HPLC, TLC | Meet predefined specifications |

| Microbiological Quality | Ensure safety | Total viable count, pathogen testing | Comply with pharmacopeial limits |

| Contaminant Testing | Detect harmful residues | Heavy metals, pesticides, mycotoxins analysis | Below regulatory thresholds |

| Marker Compound Quantification | Standardize potency | HPLC-MS, LC-MS, reference standards | Consistent across batches |

Q4: How can traditional preparation methods be reconciled with modern extraction protocols? A4: Research should:

- Document Traditional Methods: Precisely record traditional preparation techniques (infusion times, solvent types, temperature controls) used by knowledge holders [15] [16].

- Compare Extraction Efficiency: Systematically evaluate traditional methods against modern techniques for biomarker yield and biological activity.

- Validate Traditional Knowledge: Identify scientific rationale behind traditional methods (e.g., why specific solvents or preparation times are used) [13] [17].

Troubleshooting Common Experimental Challenges

Problem: Inconsistent biological activity between batches of the same herbal material.

Possible Causes & Solutions:

- Cause 1: Improper plant identification or seasonal variation

- Cause 2: Suboptimal extraction method for target compounds

- Solution: Match extraction method to compound chemistry: hydroalcoholic extraction for resins, low-alcohol for mucilaginous herbs, and validate extraction efficiency [18].

- Cause 3: Degradation of active constituents during processing or storage

- Solution: Conduct stability studies under various conditions (temperature, light, humidity) to establish shelf-life and optimal storage parameters [2].

Problem: Lack of correlation between traditional use and laboratory bioassay results.

Possible Causes & Solutions:

- Cause 1: Testing isolated compounds instead of whole preparations

- Solution: Investigate both single compounds and traditional combination formulas to identify synergistic effects [19].

- Cause 2: Using inappropriate disease models or endpoints

- Cause 3: Ignoring traditional preparation methods in extraction protocols

- Solution: Faithfully replicate traditional preparation methods before proceeding to standardized extracts [16].

Experimental Protocols for Validation Research

Protocol 1: Comprehensive Herbal Material Standardization

Objective: Establish consistent, quality-controlled herbal research material.

Methodology:

- Botanical Verification: Collect voucher specimens with expert identification; deposit in herbarium [13].

- Standardized Processing: Implement consistent drying conditions (temperature, duration, airflow) based on traditional knowledge where applicable.

- Chemical Fingerprinting: Develop HPLC or TLC fingerprints using reference standards; quantify marker compounds.

- Stability Testing: Monitor chemical and physical stability under controlled storage conditions over time.

Table: Research Reagent Solutions for Herbal Standardization

| Reagent/Material | Function | Application Notes |

|---|---|---|

| Reference Standards | Quantify marker compounds | Source from certified suppliers; verify purity |

| Chromatography Solvents | Extract and separate compounds | HPLC-grade for analysis; food-grade for preparations |

| Authentication Kits | Verify species identity | DNA barcoding reagents; microscopic staining solutions |

| Culture Media | Microbial quality testing | TSA, SCD agar for aerobic counts; selective media for pathogens |

Protocol 2: Ethnobotanical Data Collection and Validation

Objective: Systematically document and validate traditional knowledge.

Methodology:

- Community Engagement: Obtain free, prior, and informed consent following ethical guidelines for working with Indigenous communities [14] [17].

- Structured Interviews: Use standardized questionnaires to record plant uses, preparation methods, dosage, and administration routes.

- Cross-Verification: Interview multiple knowledge holders to verify information.

- Scientific Correlation: Analyze documented uses against phytochemical and pharmacological data.

Methodological Workflows

Research Reagent Solutions

Table: Essential Materials for Herbal Medicine Research

| Category | Specific Items | Research Function |

|---|---|---|

| Authentication | DNA barcoding kits, Microscopy stains, Herbarium supplies | Verify plant species and prevent adulteration |

| Extraction | Food-grade solvents, Standardized reference compounds | Reproduce traditional preparations and ensure consistency |

| Analysis | HPLC columns, TLC plates, Mass spectrometry standards | Quantify active constituents and create chemical fingerprints |

| Quality Control | Microbial testing media, Heavy metal analysis kits | Ensure safety and compliance with regulatory standards |

| Bioactivity Testing | Cell culture reagents, Enzyme assay kits, Animal model supplies | Evaluate pharmacological effects and mechanisms of action |

This technical support framework provides researchers with practical methodologies for bridging traditional herbal knowledge and modern scientific validation, emphasizing standardized approaches, troubleshooting guidance, and ethical collaboration with traditional knowledge holders.

A Methodological Toolkit: From Classical Pharmacognosy to Advanced Analytics

What is the primary goal of applying these classical techniques in modern herbal research? The primary goal is to ensure the quality, safety, and efficacy of herbal medicines by confirming the correct identity of raw materials, detecting adulteration, and guaranteeing batch-to-batch consistency. This standardization is a fundamental prerequisite for integrating herbal products into modern evidence-based healthcare and is emphasized in guidelines from bodies like the WHO [2] [4].

How do morphological, microscopic, and physicochemical analyses work together? These techniques form a hierarchical quality assessment chain. Morphological evaluation provides the first line of identification through gross physical inspection. Microscopic analysis offers a more detailed, structural verification that can detect adulteration even in powdered materials. Physicochemical profiling then quantifies material properties and ensures purity, creating a comprehensive quality control protocol [20] [21].

Within a thesis on standardization, what is the significance of establishing a "reference standard"? The entire standardization process depends on a well-characterized reference standard. This refers to a validated sample of the plant material against which all future batches are compared. It is typically characterized using all three classical techniques—morphology, microscopy, and physicochemical parameters—to create a definitive fingerprint that ensures consistency and reliability in research and production [20] [2].

Morphological Evaluation: Troubleshooting Guide

Issue: Observed high morphological variation between plant samples, causing identification uncertainty.

- Potential Cause: Natural phenotypic plasticity due to growing conditions (soil, climate) or misidentification of a closely related species.

- Solution:

- Standardize Assessment: Create a standardized checklist of diagnostic characters (e.g., leaf shape, margin, venation, surface texture, flower color and structure) based on an authoritative pharmacopoeia or botanical reference.

- Use Reference Samples: Always compare unknown samples directly against a verified voucher specimen.

- Document Thoroughly: Use high-resolution photography with a scale under consistent lighting. Capture details of both sides of the leaf, the stem, and flowers/fruits if available [22] [21].

Issue: Reliably distinguishing between dried plant parts that look superficially similar.

- Potential Cause: Key diagnostic features like color or smell can fade or change upon drying.

- Solution:

- Focus on Stable Characters: Prioritize structural characteristics that are less variable, such as the arrangement of flowers (inflorescence type), fruit type, and seed morphology.

- Rehydrate if Necessary: Briefly soak dried leaves or stems to restore texture and make features like venation patterns more visible.

- Corroborate with Other Techniques: This limitation highlights why morphological evaluation is only the first step and must be followed by microscopic analysis for definitive identification [21].

Microscopic Evaluation: Troubleshooting Guide

Issue: Tissue sections are too thick or fragile, resulting in poor-quality microscopic images.

- Potential Cause: Improper sectioning technique or inadequate sample preparation.

- Solution:

- Softening: For hard or dry materials, soften by soaking in a mixture of water, glycerin, and alcohol before sectioning.

- Support for Fragile Tissues: Embed fragile materials in a supporting matrix like paraffin wax or carboxymethyl cellulose (CMC) to facilitate clean, thin sectioning with a microtome.

- Clearing: Use chloral hydrate solution or lactic acid to clear the section, dissolving cytoplasmic contents and making cell walls and crystals like calcium oxalate more distinct [20] [22].

Issue: Unable to identify key diagnostic microscopic features (e.g., stomata, trichomes) with confidence.

- Potential Cause: Insufficient knowledge of the plant's typical anatomy or incorrect microscope settings.

- Solution:

- Consult Reference Atlases: Use anatomical atlases of medicinal plants or published monographs for the expected microscopic features of your specific plant.

- Utilize Staining Techniques: Employ simple stains to differentiate tissues. For example, iodine solution stains starch grains blue-black, while Sudan Red IV stains cutin and suberin in cell walls.

- Optimize Microscopy: Start with lower magnification to locate areas of interest, then switch to higher magnification (e.g., 400x) for detailed observation of stomata and trichomes. Adjust the condenser and diaphragm for optimal contrast [20].

Issue: Image analysis software provides inconsistent particle shape data.

- Potential Cause: Process variables like inconsistent sample illumination, incorrect greyscale thresholding, or an inappropriate scaling factor (µm/pixel) [23].

- Solution:

- Standardize Illumination: Ensure the light source position and intensity are consistent for all images.

- Calibrate Thresholding: Manually set and validate the greyscale threshold used to distinguish particles from the background.

- Optimize Scaling Factor: Use a scaling factor (optical magnification and pixel size) that is low enough for accurate shape estimation but high enough to maintain a practical field of view. Analyze a statistically sufficient number of particles (often 50-100) for a representative assessment [23].

Experimental Workflow for Microscopic Analysis

The diagram below outlines a standard workflow for the microscopic identification of herbal materials.

Physicochemical Evaluation: Troubleshooting Guide

Issue: Extractive values are consistently lower than the pharmacopoeial requirement.

- Potential Cause: The plant material may be too old or was dried at too high a temperature, degrading active compounds. Alternatively, the particle size of the powder may be too coarse, leading to inefficient extraction.

- Solution:

- Verify Raw Material Quality: Ensure the plant was harvested at the correct time and dried gently (e.g., air-dried in shade).

- Optimize Powder Size: Grind the simplicia to a fine, uniform powder to increase the surface area for extraction, as specified in methods like those in the Materia Medica Indonesia [20].

- Confirm Extraction Protocol: Ensure the maceration time (e.g., 6 hours shaking followed by 18 hours standing) and solvent volume are strictly adhered to [20].

Issue: High ash value, particularly acid-insoluble ash.

- Potential Cause: Contamination with silica-rich earthy materials like sand and soil, or improper cleaning of the raw plant material.

- Solution:

- Improve Raw Material Handling: Implement stricter washing and cleaning procedures for the harvested plant parts.

- Control Source: Audit the cultivation and harvesting practices to minimize soil contamination.

- Interpret Results: The acid-insoluble ash value specifically indicates silicate contamination, and a high value fails quality standards, as seen in requirements where it must not be more than 3% [20].

Issue: Unclear or overlapping spots on TLC plates.

- Potential Cause: Inappropriate mobile phase composition, sample overloading, or an undersaturated TLC chamber.

- Solution:

- Optimize Mobile Phase: Research literature for established mobile phases for your plant's compound class (e.g., hexane-acetone 3:2 v/v for some compounds in Ruta angustifolia) and adjust ratios slightly for better separation [20].

- Dilute Sample: Spot a more dilute sample solution to prevent overloading.

- Saturate Chamber: Ensure the TLC development chamber is properly lined with filter paper and saturated with the mobile phase vapor for at least 20-30 minutes before introducing the plate.

Key Physicochemical Parameters for Quality Control

The following table summarizes standard physicochemical tests and their acceptable criteria, as exemplified by research on Ruta angustifolia leaves, which adhered to the Materia Medica Indonesia [20].

| Parameter | Purpose | Typical Method | Exemplary Result & Requirement |

|---|---|---|---|

| Loss on Drying | Measures moisture content; affects stability & risk of microbial growth. | Drying at 105°C to constant weight. | 10.02% (Requirement: ≤10%) [20] |

| Total Ash | Measures total inorganic residue; indicates mineral content & earthy matter. | Incineration at 600°C. | 10.75% (Requirement: ≥10%) [20] |

| Acid-Insoluble Ash | Measures silicate contaminants like sand and soil. | Ash treated with dilute HCl and reignited. | 0.52% (Requirement: ≤3%) [20] |

| Water-Soluble Extract | Estimates content of water-soluble compounds (e.g., tannins, sugars). | Maceration with water, evaporation, weighing. | 27.14% (Requirement: ≥28%) [20] |

| Ethanol-Soluble Extract | Estimates content of alcohol-soluble compounds (e.g., resins, alkaloids). | Maceration with 95% ethanol, evaporation, weighing. | 20.17% (Requirement: ≥8%) [20] |

| Heavy Metals | Ensures safety by quantifying toxic elements (Pb, Cd, As, Hg). | Atomic Absorption Spectrophotometry (AAS). | e.g., Pb: 0.12 ppm (Requirement: ≤10 ppm) [20] |

Experimental Workflow for Physicochemical Standardization

The diagram below illustrates the logical sequence of key tests in a physicochemical profiling workflow.

The Scientist's Toolkit: Essential Research Reagents & Materials

The following table lists key reagents and materials required for performing the classical evaluations discussed.

| Item | Primary Function |

|---|---|

| Chloral Hydrate | A clearing agent used in microscopic slide preparation to dissolve cytoplasm and chlorophyll, making cell walls and crystals clearly visible [20]. |

| Reference Standard (Plant Material) | A botanically verified and fully characterized sample of the plant, serving as the benchmark for all morphological, microscopic, and chemical comparisons [20] [2]. |

| Silica Gel GF254 (TLC Plates) | The stationary phase for Thin Layer Chromatography (TLC); used for the fingerprinting and separation of chemical compounds like flavonoids and alkaloids [20]. |

| Specific Spray Reagents (e.g., Dragendorff's, FeCl₃) | Chemical developers used on TLC plates to visualize specific classes of compounds (e.g., Dragendorff's for alkaloids, FeCl₃ for phenolics) [20]. |

| HPLC-grade Solvents (e.g., Acetonitrile) | High-purity solvents used as the mobile phase in High-Performance Liquid Chromatography (HPLC) to generate precise phytochemical profiles for quantification [20]. |

| Simulated Gastric/Intestinal Fluids | Buffered solutions used in stability testing to determine how an herbal extract or formulation degrades in the gastrointestinal environment [24]. |

Chromatographic Fingerprinting (TLC, HPTLC, HPLC) for Metabolite Profiling

Chromatographic fingerprinting is an analytical methodology that uses an instrumental signal, such as a chromatogram, to obtain non-obvious information about the chemical composition of a complex sample, like an herbal preparation [25]. This fingerprint serves as a unique identity card for the material, enabling both identity and quality testing [25] [26]. Within the critical field of herbal medicine research, this technique is indispensable for standardization, ensuring product consistency, detecting adulteration, and confirming authenticity, thereby directly supporting the efficacy and safety of herbal products [1].

This technical support center provides researchers and scientists with foundational knowledge, detailed protocols, and troubleshooting guides for implementing chromatographic fingerprinting in herbal medicine standardization.

Key Concepts and Methodologies

What is Chromatographic Fingerprinting?

Chromatographic fingerprinting is an analytical methodology that uses a chromatographic signal (the "fingerprint") to obtain information about a material's identity or quality, which is linked to its chemical composition [25]. The information within the fingerprint is implicit and non-specific, meaning it is not obviously tied to individual compounds. Extracting this information requires the application of chemometric data-mining tools on a large set of representative fingerprints [25] [26].

Fingerprinting vs. Profiling:

- Fingerprinting: A high-throughput process aimed at rapidly uncovering compositional differences between samples without necessarily achieving precise quantification or identification of all constituents. The goal is to use the entire chromatographic signal as a differentiating pattern [26].

- Profiling: An approach focused on obtaining detailed qualitative and/or quantitative information on the distribution of a sample's components, either for a pre-defined set of targets (targeted profiling) or for all detected constituents (untargeted profiling) [26].

General Workflow for Chromatographic Fingerprinting

The diagram below illustrates the logical sequence of steps for developing a chromatographic fingerprinting method.

Detailed Experimental Protocols

Protocol for Untargeted Metabolomic Analysis via LC-MS

This protocol is adapted for herbal medicine analysis and is based on a standard untargeted metabolomics workflow [27].

1. Sample Preparation:

- Extraction: Weigh a representative amount of the powdered herbal material. Extract using a solvent system suitable for polar metabolites, such as acetonitrile:methanol:formic acid (74.9:24.9:0.2, v/v/v). Vortex and centrifuge to pellet insoluble debris [27].

- Internal Standards: Incorporate stable isotope-labeled internal standards (e.g., l-Phenylalanine-d8 and l-Valine-d8) into the extraction solvent. This controls for variability during sample preparation and analysis [27].

2. Chromatographic Separation (HILIC for Polar Metabolites):

- Column: Use a hydrophilic interaction liquid chromatography (HILIC) column (e.g., Waters Atlantis HILIC Silica) for separating polar compounds.

- Mobile Phases:

- Mobile Phase A: 10 mM ammonium formate with 0.1% formic acid in LC/MS-grade water.

- Mobile Phase B: 0.1% formic acid in LC/MS-grade acetonitrile.

- Gradient: Employ a gradient elution starting with a high percentage of B (e.g., 85-95%) to retain polar metabolites, gradually increasing A to elute them. The total run time should be optimized for speed while retaining critical information, ideally under 10 minutes where possible [25].

3. Data Acquisition:

- Use a high-resolution mass spectrometer (e.g., Orbitrap or Q-ToF) for accurate mass measurement.

- Acquire data in both positive and negative ionization modes to maximize metabolite coverage.

4. Data Processing:

- Use software (e.g., Thermo Compound Discoverer, open-source tools) for peak picking, alignment, and deconvolution.

- Export a peak intensity table (features × samples) for subsequent chemometric analysis.

Protocol for Herbal Authentication via HPTLC

This protocol supports the authenticity testing required for herbal quality control [1].

1. Sample and Standard Preparation:

- Prepare methanolic or ethanolic extracts of the herbal test samples.

- Prepare a reference standard solution from an authenticated botanical sample of the same species.

2. Application and Development:

- Apply test and reference extracts as bands on an HPTLC plate (e.g., silica gel).

- Develop the plate in a saturated twin-trough chamber with a suitable mobile phase (e.g., ethyl acetate:glacial acetic acid:formic acid:water). Develop until the solvent front has migrated an appropriate distance.

3. Derivatization and Documentation:

- Dry the plate and visualize using appropriate reagents (e.g., anisaldehyde-sulfuric acid for terpenes, natural product reagent for flavonoids).

- Document the plate under UV (254 nm and 366 nm) and white light after derivatization using a digital imaging system.

4. Fingerprint Analysis:

- Compare the banding patterns (Rf values, colors) of the test samples against the reference standard. The pattern serves as the fingerprint for authentication [1].

Troubleshooting Guides and FAQs

HPLC Troubleshooting Guide

Table: Common HPLC Issues and Solutions

| Problem | Possible Causes | Recommended Solutions |

|---|---|---|

| Baseline Noise | Air bubbles in system; Detector cell contaminated; Detector lamp failure [28] | Degas mobile phase; purge system; clean or replace detector cell/flow; replace lamp [28] |

| Baseline Drift | Column temperature fluctuation; Mobile phase composition change; Poor column equilibration [28] | Use a column oven; prepare fresh mobile phase; increase equilibration time with new mobile phase [28] |

| Peak Tailing | Active sites on column; Blocked column; Inappropriate mobile phase pH [28] | Change column; reverse-flush column; adjust mobile phase pH [28] |

| Retention Time Drift | Poor temperature control; Incorrect mobile phase composition; Change in flow rate [28] | Use a thermostat column oven; prepare fresh mobile phase; check and reset flow rate [28] |

| Broad Peaks | Flow rate too low; Column overloading; Column contamination [28] | Increase flow rate; decrease injection volume; replace guard/analytical column [28] |

| High Pressure | Column blockage; Flow rate too high; Mobile phase precipitation [28] | Backflush column; lower flow rate; flush system and prepare fresh mobile phase [28] |

Frequently Asked Questions (FAQs)

Q1: Why is my chromatographic fingerprint for the same herbal batch showing high variability? A1: Inconsistency often stems from inadequate quality control during the initial steps. Ensure standardized sample collection, authentication of herbal ingredients, and strict adherence to the sample preparation protocol (extraction solvent, time, temperature) [1] [4]. Using stable isotope-labeled internal standards can help monitor and correct for this variability [27].

Q2: When should I use a targeted vs. a non-targeted (fingerprinting) approach? A2: Use a targeted approach when you need to accurately quantify a specific, pre-defined set of marker compounds. Use a non-targeted fingerprinting approach when your goal is to compare overall sample patterns, ensure authenticity, detect unknown adulterants, or assess global changes in metabolite profiles without prior knowledge of all constituents [25] [26] [29].

Q3: What are the critical parameters for developing a robust HPLC fingerprint method? A3: The triple decision is critical [25]:

- Sample Preparation: Must be reproducible and extract the relevant compounds.

- Chromatographic Mode/Conditions: Select the appropriate column (e.g., RP-C18, HILIC) and optimize the gradient for reasonable run time and sufficient separation. For fingerprinting, shorter run times (<10 min) can be acceptable even with some resolution sacrifice [25].

- Detection Settings: Wavelength for UV/VIS or parameters for MS detection must be set to capture a wide range of compounds.

Q4: How do I validate a chromatographic fingerprinting method? A4: Validation should demonstrate that the methodology can reliably establish identity and quality [25]. This includes assessing the method's precision (repeatability of fingerprints), stability, and robustness. The developed method should be able to consistently differentiate between authentic and adulterated or low-quality samples through chemometric models [25] [1].

The Scientist's Toolkit

Research Reagent Solutions

Table: Essential Materials for Chromatographic Fingerprinting

| Item | Function / Explanation |

|---|---|

| HILIC Column | Separates polar metabolites in untargeted profiling, complementary to reversed-phase chromatography [27]. |

| Stable Isotope-Labeled Internal Standards | Added to samples to monitor and correct for variability during sample preparation and analysis, improving data quality [27]. |

| Reference Standardized Herbal Extracts | Authenticated plant extracts used as a benchmark for comparing TLC/HPTLC banding patterns or HPLC profiles to confirm the identity of test samples [1]. |

| High-Resolution Mass Spectrometer (HR-MS) | Provides accurate mass data for metabolites, enabling confident identification and structural characterization in complex herbal matrices [29]. |

| Chemometric Software | Essential for extracting hidden information from fingerprinting data; used for pattern recognition, classification, and multivariate statistical analysis [25] [26]. |

Logical Workflow for Data Analysis

After data acquisition, processing the fingerprints to extract meaningful information is crucial. The following diagram outlines the standard data analysis pathway.

Spectroscopic Methods (UV-Vis, FTIR, NMR) and DNA Barcoding for Authentication

Troubleshooting Guides

Spectroscopic Analysis: Common Issues and Solutions

Table 1: Troubleshooting UV-Vis, FTIR, and NMR Spectroscopy for Herbal Authentication

| Problem | Possible Causes | Solutions | Preventive Measures |

|---|---|---|---|

| Poor reproducibility of UV-Vis spectra | Inconsistent sample preparation; solvent effects; degradation of active compounds. | Standardize extraction protocol (e.g., solvent, time, temperature); perform analysis immediately after extraction; use degassed solvents. | Use internal standards; validate method robustness [30]. |

| FTIR spectra with low signal-to-noise ratio | Poor sample contact with ATR crystal; insufficient sample concentration; water vapor interference. | Clean ATR crystal thoroughly; ensure uniform powder for solid samples; increase scans; purge instrument with dry air. | Perform background scan immediately before sample; grind sample to fine, uniform particles [31]. |

| Overlapping peaks in NMR spectra | High complexity of herbal extract; low concentration of target analytes; solvent interference. | Use 2D-NMR techniques (e.g., COSY, HSQC) for separation; employ higher magnetic field strength; concentrate sample. | Use deuterated solvents; apply chemometrics (PCA, PLS-DA) for deconvolution [31] [30]. |

| Spectral mismatch with reference database | Natural variability due to geography, season; different processing methods; adulteration. | Develop in-house spectral libraries with authenticated samples; use chemometrics to identify marker peaks. | Apply multivariate analysis to account for acceptable variance; use multiple techniques for confirmation [30]. |

DNA Barcoding: Common Issues and Solutions

Table 2: Troubleshooting DNA Barcoding for Herbal Material Authentication

| Problem | Possible Causes | Solutions | Preventive Measures |

|---|---|---|---|

| PCR amplification failure | DNA degradation in processed herbs; presence of PCR inhibitors (e.g., polysaccharides, polyphenols). | Use mini-barcodes (shorter DNA regions); perform DNA clean-up protocols; add PCR enhancers (e.g., BSA, DMSO). | Optimize DNA extraction for specific material (fresh vs. dried); use silica-based purification columns [32] [33]. |

| Low discriminatory power | The chosen barcode region lacks sufficient sequence variation for closely related species. | Use multi-locus barcodes (e.g., ITS2+psbA-trnH); employ super-barcodes (complete plastid genome). | Select barcodes based on prior validation for the plant family (e.g., ITS2 as a core barcode for plants) [32]. |

| Inability to identify all species in a mixture | Universal primers have amplification bias; some species' DNA dominates the PCR. | Adopt DNA metabarcoding via NGS; use multiple primer sets to cover a wider taxonomic range. | For multi-ingredient products (e.g., CPMs), design the experiment for mixture analysis from the start [32] [33]. |

| Inconclusive or erroneous BLAST results | Reference sequence database lacks the species or contains misidentified sequences. | Use curated databases (e.g., BOLD Systems); cross-verify with morphological/chemical data. | Build a local, validated reference library with voucher specimens [33]. |

Frequently Asked Questions (FAQs)

Q1: Our herbal extract is a complex mixture. How can FTIR be useful when its spectrum has many overlapping peaks?

A1: While FTIR spectra of herbal extracts are complex, the overall profile serves as a chemical fingerprint. The key is not to assign every single peak but to use the entire spectral pattern for comparison. Techniques like chemometrics (e.g., Principal Component Analysis - PCA) can analyze the entire spectrum to differentiate species, detect adulterants, or assess batch-to-batch consistency, even with overlapping peaks [30]. This makes FTIR a rapid and powerful tool for quality control.

Q2: What is the most significant advantage of NMR in herbal medicine standardization compared to other spectroscopic methods?

A2: The primary advantage of NMR is its ability to provide simultaneous qualitative and quantitative information in a single, non-destructive analysis. It can identify multiple compounds and measure their absolute concentrations without requiring specific reference standards for every compound, which is a limitation of chromatographic methods. This makes it exceptionally powerful for profiling the complex, multi-constituent nature of herbal medicines and for detecting unexpected adulterants [31] [30].

Q3: When should we use "mini-barcodes" instead of conventional DNA barcodes?

A3: Use mini-barcodes when working with herbal materials where the DNA is highly degraded, such as in processed products, Chinese patent medicines (CPMs), heat-treated powders, or aged specimens. Conventional barcodes are longer and may not amplify from fragmented DNA, whereas mini-barcodes are short enough to target and sequence from damaged DNA templates, thereby improving identification success [32].

Q4: Our laboratory needs to identify the plant species in a multi-herb formulation. Can DNA barcoding handle this?

A4: Yes, but conventional Sanger sequencing of a single barcode cannot. The solution is DNA metabarcoding, a next-generation sequencing (NGS) approach. It allows for the simultaneous sequencing of DNA barcodes from all species present in a complex mixture, enabling the identification of multiple ingredients from a single sample. This is a major advancement for quality control of multi-herb products [33].

Q5: For quality control, is it better to use chemical fingerprinting (e.g., HPLC, FTIR) or DNA barcoding?

A5: They are complementary, not substitutable, and should be used together for a comprehensive quality assessment.

- DNA barcoding is superior for species authentication—answering "Is this the correct species?" It is highly specific and unaffected by environmental factors or the plant's physiological state.

- Chemical fingerprinting is essential for quality evaluation—answering "Does this sample contain the expected profile of chemical compounds in the right proportions?" It directly assesses the chemical composition, which is linked to efficacy.

A combination of both methods provides the most robust standardization, ensuring both correct identity and desired chemical quality [30].

Experimental Protocols

Detailed Protocol: DNA Metabarcoding for Multi-Ingredient Herbal Products

This protocol is adapted for identifying component species in complex herbal products like tablets or granules [32] [33].

Workflow Overview:

Step-by-Step Methodology:

DNA Extraction:

- Grind the sample to a fine powder using a sterile mortar and pestle or a tissue lyser.

- Use a commercial plant DNA extraction kit (e.g., DNeasy Plant Pro Kit from QIAGEN) designed to remove polysaccharides and polyphenols, which are common PCR inhibitors.

- Quantify the extracted DNA using a fluorometer (e.g., Qubit). Assess quality via agarose gel electrophoresis or Bioanalyzer. Expect fragmented DNA (100-500 bp) in processed products.

PCR Amplification (DNA Metabarcoding):

- Select one or more mini-barcode regions suitable for degraded DNA, such as ITS2, mini-rbcL, or the trnL P6 loop [33].

- Perform PCR in triplicate for each sample to mitigate amplification bias. Use high-fidelity DNA polymerase.

- Primer Example (ITS2): Forward:

5'-GTGAATCATCGAATCTTTGAA-3', Reverse:5'-CGCACATCCGCAACACGAGC-3'(with overhang adapters for NGS).

Library Preparation and Sequencing:

- Purify the pooled PCR products using solid-phase reversible immobilization (SPRI) beads (e.g., Ampure XP).

- Attach dual-indexed sequencing adapters to the amplicons via a limited-cycle PCR.

- Pool the final, uniquely indexed libraries in equimolar ratios. Sequence on an Illumina MiSeq or HiSeq platform (2x250 bp or 2x300 bp chemistry is typical).

Bioinformatics Analysis:

- Demultiplexing: Assign raw reads to each sample based on their unique indexes.

- Quality Filtering & Trimming: Use tools like

TrimmomaticorCutadaptto remove low-quality bases, primers, and adapters. - Clustering: Cluster high-quality reads into Operational Taxonomic Units (OTUs) at 97-100% similarity or denoise into Amplicon Sequence Variants (ASVs) using

DADA2orUNOISE3. - Taxon Assignment: BLAST the representative sequences from each cluster against a curated reference database (e.g., NCBI GenBank, BOLD Systems). Confirm identifications with a high-scoring segment pair (HSP) and a high percentage identity (e.g., >98-99%).

Detailed Protocol: FTIR Fingerprinting with Chemometric Analysis

This protocol outlines the creation of a chemical fingerprint for species differentiation and adulteration detection [31] [30].

Workflow Overview:

Step-by-Step Methodology:

Standardized Sample Preparation:

- Powder authenticated plant material to a consistent particle size (e.g., sieved through a 100-mesh screen).

- For ATR-FTIR, place the powder directly on the crystal and apply consistent pressure using the instrument's anvil.

- For transmission mode, create a KBr pellet by homogenously mixing 1-2 mg of sample with 200 mg of dry KBr and pressing under vacuum.

FTIR Spectral Acquisition:

- Acquire spectra in the mid-IR range (4000-400 cm⁻¹).

- Set resolution to 4 cm⁻¹ and accumulate 32-64 scans per spectrum to ensure a high signal-to-noise ratio.

- Collect a background spectrum before every sample or set of samples.

Spectral Pre-processing:

- Use software (e.g., MATLAB with PLS_Toolbox, R, or Python with SciPy) for pre-processing.

- Apply techniques sequentially:

- Atmospheric Suppression: Remove CO₂ (~2350 cm⁻¹) and H₂O vapor bands.

- Baseline Correction: To correct for scattering effects.

- Vector Normalization or Standard Normal Variate (SNV): To minimize the effects of path length and particle size.

Chemometric Modeling:

- Principal Component Analysis (PCA): An unsupervised method to explore natural clustering of samples and identify outliers.

- Partial Least Squares-Discriminant Analysis (PLS-DA): A supervised method to build a classification model that maximizes the separation between pre-defined groups (e.g., different species). Validate the model using cross-validation and a separate test set of samples.

Research Reagent Solutions

Table 3: Essential Materials for Herbal Authentication Experiments

| Category | Item / Reagent | Function / Application | Example Kits / Vendors |

|---|---|---|---|

| DNA-Based Authentication | Plant DNA Extraction Kit | Isolates high-quality DNA, free of inhibitors, from complex herbal matrices. | DNeasy Plant Pro Kit (QIAGEN), NucleoSpin Plant II (Macherey-Nagel) |

| Universal Barcode Primers | Amplifies standardized genomic regions for species identification. | Pre-designed primers for ITS2, rbcL, matK, psbA-trnH [32] | |

| High-Fidelity DNA Polymerase | Ensures accurate amplification for sequencing and library construction. | Q5 (NEB), Phusion (Thermo Scientific) | |

| SPRI Magnetic Beads | Purifies and size-selects DNA fragments post-amplification for NGS. | Ampure XP Beads (Beckman Coulter) | |

| Spectroscopic Analysis | Deuterated Solvents | Required for NMR spectroscopy to provide a stable lock signal. | DMSO-d6, CDCl₃, CD₃OD (e.g., from Sigma-Aldrich, Cambridge Isotopes) |

| ATR Crystals | Enables direct, non-destructive sampling for FTIR. | Diamond, ZnSe (Standard in FTIR spectrometers like Thermo Nicolet, Bruker) | |

| Internal Standards | Provides a reference for quantitative NMR (qNMR). | Dimethyl sulfone (DMS), Maleic acid [30] | |

| General & Quality Control | Authenticated Reference Plant Material (ARPM) | Provides a verified standard for comparison in all identification methods. | Supplied by botanical gardens, USP, or specialized herbaria [34] [30] |

| Chemical Reference Standards (Markers) | Used as benchmarks for chromatographic and spectroscopic quantification. | Active principles, analytical markers (e.g., curcumin, ginsenosides) [34] |

Implementing WHO GMP and Quality Control Parameters for Herbal Manufacturers

Frequently Asked Questions (FAQs) on WHO GMP & Standardization

FAQ 1: What is the core objective of WHO GMP for herbal medicines? The primary objective is to ensure that herbal products are consistently produced and controlled to the quality standards appropriate to their intended use [35]. It is a part of a quality management system aimed at diminishing the risks inherent in any pharmaceutical production, which can be broadly categorized into cross-contamination, mix-ups, and false labelling [35]. Above all, the goal is to ensure that manufacturers do not place patients at risk due to inadequate safety, quality, or efficacy.

FAQ 2: What are the key WHO quality control parameters for authenticating raw herbal materials? Authentication of raw materials is the critical first step. The key parameters and methods include [2] [1] [36]:

- Macroscopic & Microscopic Examination: Visual and microscopic inspection to identify correct plant species and plant parts.

- DNA Barcoding: A molecular technique used for authenticating species, such as Panax ginseng, to avoid misidentification [2].

- Chromatographic Fingerprinting: Techniques like Thin-Layer Chromatography (TLC) and High-Performance Liquid Chromatography (HPLC) are used to create a unique chemical profile of the herb, confirming identity and quantifying active compounds [2] [1].

FAQ 3: Our herbal extract shows batch-to-batch variation in potency. How can we improve consistency? Batch-to-batch variation is a common challenge addressed through extraction process validation and standardization [2] [1]. You must:

- Validate Extraction Parameters: Standardize and validate the methods for extraction (e.g., solvent, temperature, time) to ensure reliable and consistent extraction of bioactive constituents [2].

- Implement In-Process Controls: Monitor critical steps during manufacturing to detect and address deviations early [2] [37].