Scalable Production of MSC-Derived Exosomes: Optimizing Culture Conditions for Clinical Translation

This article provides a comprehensive guide for researchers and drug development professionals on scaling up mesenchymal stem cell (MSC) culture to produce therapeutic exosomes.

Scalable Production of MSC-Derived Exosomes: Optimizing Culture Conditions for Clinical Translation

Abstract

This article provides a comprehensive guide for researchers and drug development professionals on scaling up mesenchymal stem cell (MSC) culture to produce therapeutic exosomes. It covers foundational principles of MSC-exosome biology, explores advanced 3D bioreactor systems and purification methodologies, and offers practical strategies for troubleshooting batch variability and optimizing critical quality attributes. The content synthesizes the latest 2025 research to present a validated framework for achieving high-yield, consistent, and potent exosome production, directly addressing the key challenges in translating cell-free therapies from the laboratory to the clinic.

MSC-Exosome Biology and Preconditioning for Enhanced Potency

Frequently Asked Questions (FAQs): Core Concepts

Q1: What are the primary safety advantages of using MSC-derived exosomes over whole MSC therapy?

MSC-derived exosomes offer a cell-free therapeutic profile that circumvents key risks associated with whole cell transplantation. Major safety advantages include:

- Lower Immunogenicity: Exosomes lack major histocompatibility complex (MHC) molecules, significantly reducing the risk of immune rejection [1] [2].

- Reduced Tumorigenic Risk: Unlike live cells, exosomes are non-replicating, eliminating the risk of unwanted differentiation or tumor formation [1] [2].

- Avoidance of Vascular Complications: Their nanoscale size prevents capillary blockage (embolism), a potential risk with larger cell infusions [3].

- Higher Stability and Ease of Storage: Exosomes are easier to preserve and store compared to live cells, simplifying logistics for clinical applications [4].

Q2: Through what key mechanisms do MSC-derived exosomes exert their therapeutic effects?

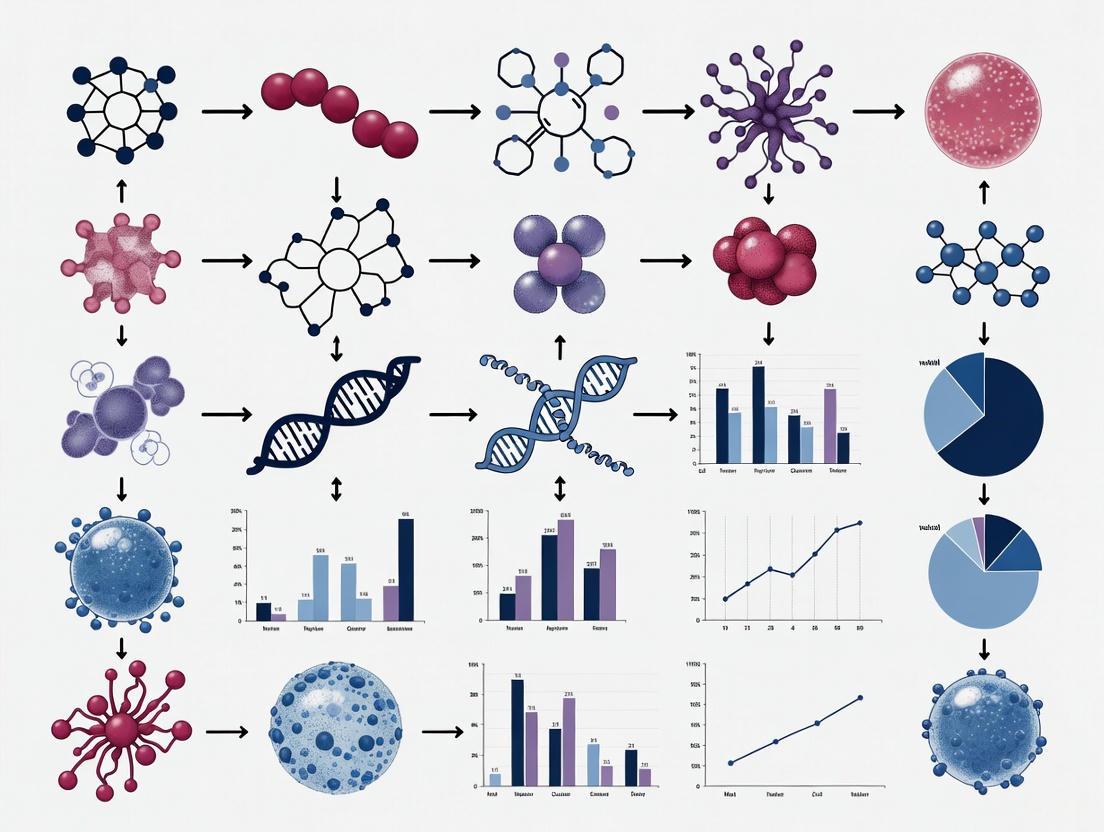

MSC-derived exosomes function primarily through intercellular communication, mediating their effects via several core mechanisms summarized in the diagram below:

The primary mechanisms are:

- Bioactive Cargo Delivery: Exosomes transfer functional miRNAs, proteins, and lipids to recipient cells, modulating key signaling pathways (e.g., Wnt/β-catenin for hair regeneration, AKT/ERK for renal repair) [1] [3].

- Immune Cell Modulation: They directly influence immune cells by suppressing T and B cell proliferation, promoting anti-inflammatory M2 macrophage polarization, and reducing natural killer cell cytotoxicity [1] [4].

- Promotion of Tissue Repair: Exosomes enhance cell proliferation and survival, reduce apoptosis and oxidative stress, and stimulate angiogenesis, facilitating tissue regeneration [3] [5].

Troubleshooting Guides: Common Experimental Challenges

Challenge 1: Low Yield and Scalability in Exosome Production

Low exosome yield is a major bottleneck for preclinical and clinical studies [6].

Potential Causes and Solutions:

- Cause: Suboptimal Cell Culture Conditions.

- Solution: Transition from 2D static culture to 3D bioreactor systems (e.g., Hollow Fiber bioreactors). These systems significantly increase cell density and prolong productive culture duration, enhancing yield [7]. Optimization of basal culture media (e.g., α-MEM may support higher yields than DMEM) and the use of xeno-free supplements like human platelet lysate (hPL) can also improve cell growth and exosome secretion [5].

- Cause: Inefficient Isolation Method.

- Solution: Replace traditional ultracentrifugation (UC) with more efficient, scalable methods like Tangential Flow Filtration (TFF). TFF allows for processing large volumes of conditioned media with higher recovery rates and better preservation of exosome integrity [5].

Recommended Protocol: Scalable Production using a Hollow Fiber Bioreactor [7]

- Cell Expansion: Seed human umbilical cord-derived MSCs (hUC-MSCs) into a Hollow Fiber 3D bioreactor.

- Conditioned Media Collection: Use a defined exosome-production medium (e.g., RoosterBio exosome-harvesting system) and harvest conditioned media periodically over a 28-day production cycle.

- Primary Concentration: Use TFF to concentrate the conditioned media.

- Exosome Isolation & Purification: Further purify the concentrated solution using size-exclusion chromatography (SEC) or density gradient centrifugation to remove contaminating proteins.

- Characterization: Analyze the final product using Nanoparticle Tracking Analysis (NTA), transmission electron microscopy (TEM), and western blot (for CD63, CD81, TSG101) to confirm yield, size, and marker expression.

Challenge 2: Heterogeneity and Lack of Functional Consistency

Exosome preparations are often heterogeneous, leading to variable experimental outcomes [7] [8].

Potential Causes and Solutions:

- Cause: Inherent Biological Variability.

- Solution: Standardize the cell source and passage number. Implement rigorous quality control for the parent MSCs, including surface marker profiling and differentiation potential assays. Establish a consistent "collection window" (e.g., specific passages) for harvesting exosomes to ensure subpopulation stability [7].

- Cause: Presence of Non-Exosomal Contaminants.

Recommended Protocol: Functional Consistency Testing in a Disease Model [7]

To ensure functional consistency, especially when scaling up, validate batches in a relevant disease model.

- In Vivo Model: Utilize a silica-induced mouse model of silicosis.

- Administration: Test the therapeutic efficacy via respiratory delivery (nebulization).

- Assessment: Evaluate outcomes through histology (e.g., lung tissue fibrosis scoring) and analysis of inflammatory biomarkers (e.g., cytokine levels in bronchoalveolar lavage fluid).

- Benchmarking: Compare the effects of new exosome batches against a well-characterized reference batch to ensure consistent biological activity.

Challenge 3: Inefficient Delivery and Biodistribution

The route of administration critically determines exosome delivery and therapeutic efficacy [7] [8].

Potential Causes and Solutions:

- Cause: Unsuitable Administration Route.

- Cause: Lack of Biodistribution Data.

- Solution: Track exosomes in vivo using isotopic labeling (e.g., with Zirconium-89, ⁸⁹Zr) to study their tissue tropism and pharmacokinetics, which informs optimal dosing and route selection [7].

Recommended Protocol: Evaluating Administration Routes [7] [8]

- Labeling: Label purified exosomes with a radioactive isotope (e.g., ⁸⁹Zr) or a fluorescent dye (e.g., DiR).

- Administration: Administer the labeled exosomes to animal models via two different routes (e.g., intravenous vs. nebulization).

- Tracking: Use imaging techniques (e.g., PET/CT for radioactive labels, IVIS for fluorescent labels) at multiple time points to monitor real-time biodistribution.

- Correlation with Efficacy: Sacrifice the animals and correlate the biodistribution data with therapeutic outcomes in the target tissue.

The Scientist's Toolkit: Essential Reagents and Materials

The following table details key reagents and tools critical for optimizing MSC culture and exosome production.

| Research Reagent / Material | Function / Application | Key Consideration |

|---|---|---|

| Hollow Fiber Bioreactor | 3D culture system for high-density cell expansion and continuous exosome harvest [7]. | Enables long-term (e.g., 28-day) production, improving yield and scalability over 2D flasks. |

| Tangential Flow Filtration (TFF) | Scalable isolation and concentration of exosomes from large volumes of conditioned media [5]. | Superior to ultracentrifugation for yield, processing time, and preserving exosome integrity. |

| RoosterBio Exosome System | A commercially available, integrated system including culture media and harvest supplements [7]. | Designed to enhance exosome yield and provide a standardized, xeno-free platform. |

| Human Platelet Lysate (hPL) | Xeno-free supplement for MSC culture media, replacing fetal bovine serum (FBS) [5]. | Avoids introduction of non-human vesicles and aligns with clinical translation requirements. |

| Size-Exclusion Chromatography (SEC) | High-purity purification of exosomes after initial concentration [2]. | Effectively separates exosomes from soluble proteins and other contaminants. |

| Nanoparticle Tracking Analysis (NTA) | Characterizes exosome particle size distribution and concentration [5]. | Essential for quality control and dose standardization (particles/mL). |

To aid in experimental design, key quantitative findings from recent studies are summarized below.

Table 1: Quantitative Data on Production and Dosing

| Parameter | Findings / Value Range | Context / Source |

|---|---|---|

| Production Yield | TFF isolation yielded statistically higher particle counts than Ultracentrifugation (UC) [5]. | Critical for selecting isolation methodology. |

| Production Duration | A 28-day biomanufacturing workflow in a Hollow Fiber bioreactor demonstrated stable subpopulation harvesting [7]. | Informs long-term production planning. |

| Effective Nebulized Dose | Therapeutic effects in lung disease models observed at doses around 10⁸ particles [8]. | Significantly lower than IV doses, highlighting route efficiency. |

| Intravenous Biodistribution | Predominant accumulation in the liver following IV injection [7]. | Crucial for planning systemic administration studies. |

Frequently Asked Questions (FAQs)

Q1: What are the primary therapeutic effects associated with miR-21, miR-146, and miR-181a in MSC-derived exosomes? A1: These miRNAs are key mediators of the immunomodulatory and regenerative effects of MSC-exosomes. miR-21 promotes cell survival and reduces apoptosis, miR-146a is a potent anti-inflammatory agent that suppresses the NF-κB pathway, and miR-181a regulates immune cell differentiation and function, particularly T-cell responses.

Q2: How can I efficiently isolate and quantify these specific miRNAs from my MSC-exosome preparations? A2: The recommended protocol involves total RNA isolation using kits optimized for small RNAs (e.g., miRNeasy Micro Kit), followed by reverse transcription with stem-loop primers specific to each miRNA. Quantification is best performed via RT-qPCR using TaqMan or SYBR Green assays designed for mature miRNA sequences.

Q3: My MSC culture conditions seem to alter the miRNA cargo profile. How can I standardize this?

A3: miRNA cargo is highly sensitive to culture conditions. To standardize production, control for passage number (use low passage MSCs,

Q4: What is the best method to confirm the functional delivery of these miRNAs to target cells? A4: Transfect MSC-exosomes with Cy3 or Cy5 fluorescently labeled mimics of your miRNA of interest and image uptake in target cells. For functional confirmation, transfect MSCs with a miRNA inhibitor (antagomir) prior to exosome collection, then demonstrate loss of the expected therapeutic effect in the target assay.

Troubleshooting Guides

Problem: Low yield of total RNA from isolated exosomes.

- Potential Cause 1: Inefficient exosome lysis.

- Solution: Add a membrane disruption reagent like 2% β-mercaptoethanol directly to the lysis buffer. Vortex vigorously for 15 seconds after adding the lysis buffer.

- Potential Cause 2: RNA loss during precipitation or column binding.

- Solution: Include a carrier (e.g., glycogen) during precipitation steps. Ensure ethanol concentrations are correct for column-based kits. Perform a second elution with pre-heated nuclease-free water to maximize yield.

Problem: High Ct values or non-detectable levels of target miRNAs in RT-qPCR.

- Potential Cause 1: Inefficient reverse transcription of mature miRNAs.

- Solution: Use stem-loop RT primers specifically designed for the mature miRNA sequence, not the pre-miRNA. Confirm the primer sequences are correct for the species (human, mouse, rat).

- Potential Cause 2: Purity of exosome preparation.

- Solution: Contaminating proteins from FBS or cell debris can inhibit RT and qPCR. Re-pellet exosomes and wash with PBS. Use a more stringent isolation method like density gradient centrifugation.

Problem: Inconsistent therapeutic effects between MSC-exosome batches.

- Potential Cause 1: Variability in MSC source and culture.

- Solution: Use standardized, characterized, low-passage MSCs from a reliable source. Maintain meticulous records of culture confluence at harvest and media batch numbers. Implement a serum-free media protocol.

- Potential Cause 2: Fluctuations in key miRNA cargo levels.

- Solution: Perform QC on each exosome batch by quantifying a panel of key miRNAs (miR-21, -146a, -181a) via RT-qPCR and normalize to particle number (e.g., by NTA). Only use batches that meet a pre-defined miRNA/potency threshold.

Experimental Protocols

Protocol 1: Quantifying miRNA Cargo from MSC-Exosomes

Title: miRNA Extraction & Quantification from Exosomes

Methodology:

- Exosome Isolation: Isolve exosomes from 10 mL of conditioned MSC media via ultracentrifugation (100,000 × g, 70 min) or size-exclusion chromatography. Resuspend the pellet in 200-500 µL of PBS.

- RNA Extraction: Use the miRNeasy Micro Kit (Qiagen) or equivalent.

- Add 700 µL Qiazol Lysis Reagent to 200 µL of exosome suspension. Vortex for 1 min.

- Incubate for 5 min at room temperature.

- Add 140 µL chloroform, shake vigorously for 15 sec, incubate 3 min.

- Centrifuge at 12,000 × g for 15 min at 4°C.

- Transfer the upper aqueous phase to a new tube.

- Add 1.5 volumes of 100% ethanol. Mix.

- Transfer mixture to an RNeasy MinElute spin column. Centrifuge.

- Wash with RWT and RPE buffers per kit instructions.

- Elute RNA in 14 µL nuclease-free water.

- Reverse Transcription: Use the TaqMan MicroRNA Reverse Transcription Kit with gene-specific stem-loop primers.

- Prepare RT master mix per kit instructions.

- Use 5 µL of extracted RNA.

- Run in a thermal cycler: 16°C for 30 min, 42°C for 30 min, 85°C for 5 min.

- qPCR Amplification:

- Dilute RT product 1:5.

- Prepare qPCR mix with TaqMan Universal Master Mix II and the specific TaqMan miRNA assay.

- Run in a real-time PCR system using standard cycling conditions.

- Use snoRNA234 or U6 snRNA as an endogenous control for data normalization (ΔΔCt method).

Protocol 2: Modifying MSC miRNA Cargo via Pre-conditioning

Title: Pre-conditioning MSCs to Modulate Exosomal miRNA

Methodology:

- Select Pre-conditioning Stimulus:

- Inflammatory priming: Treat MSCs at 70-80% confluence with 20 ng/mL IFN-γ and 15 ng/mL TNF-α for 24-48 hours.

- Hypoxic conditioning: Culture MSCs in a hypoxia chamber (1-3% O₂) for 48 hours.

- Harvest Conditioned Media: Collect media after preconditioning. Centrifuge at 2,000 × g for 10 min to remove cells and debris.

- Isolate Exosomes: Proceed with standard exosome isolation (e.g., ultracentrifugation, SEC, or TFF).

- Validate Cargo Changes: Extract RNA from the isolated exosomes and perform RT-qPCR for miR-146a, miR-21, and miR-181a. Compare fold-changes to exosomes from untreated, normoxic MSCs.

Table 1: miRNA Cargo Changes in MSC-Exosomes Under Different Culture Conditions

| miRNA | Condition (vs. Standard 2D) | Fold Change | Measured Effect | Reference Model |

|---|---|---|---|---|

| miR-21 | 3D Spheroid Culture | 3.5 - 5.0 ↑ | Enhanced cardiomyocyte survival | In vitro (H9C2 cells) |

| miR-146a | IFN-γ/TNF-α Priming | 8.0 - 12.0 ↑ | Suppressed macrophage TNF-α secretion | In vitro (LPS-stimulated macrophages) |

| miR-181a | Hypoxia (1% O₂) | 2.0 - 4.0 ↑ | Reduced T-cell proliferation | In vitro (PBMC assay) |

| miR-21 | High Passage (P10 vs P3) | 0.4 - 0.6 ↓ | Reduced anti-apoptotic effect | In vitro (HK-2 cells) |

Table 2: Functional Outcomes of MSC-Exosome miRNA Modulation

| Target miRNA | Modulation Method | In Vivo Model | Key Quantitative Outcome |

|---|---|---|---|

| miR-21 | Overexpression in MSCs | Mouse MI Model | 40% reduction in infarct size; 2.1-fold increase in capillary density vs. control exosomes. |

| miR-146a | Knockdown in MSCs | Mouse Colitis Model | Abolished protective effect: Disease Activity Index increased from 3.2 to 7.8 (control exo vs. KO exo). |

| miR-181a | Hypoxic Pre-conditioning | Mouse GvHD Model | 60% increase in survival rate at day 60; 50% reduction in pathological score for liver and skin. |

Pathway Diagrams

Title: MSC-Exosome miRNA Signaling Pathways

Title: miRNA Cargo Analysis Workflow

The Scientist's Toolkit: Research Reagent Solutions

| Reagent / Material | Function / Application |

|---|---|

| miRNeasy Micro Kit (Qiagen) | Isolation of high-quality total RNA, including small RNAs < 200 nt, from low-yield samples like exosomes. |

| TaqMan MicroRNA Assays (Thermo Fisher) | Sequence-specific primers and probes for highly sensitive and specific detection of mature miRNAs via RT-qPCR. |

| CD63/CD81/CD9 Antibodies | Antibodies for western blot analysis to confirm the presence of exosomal tetraspanin markers during characterization. |

| Exosome-depleted FBS | Fetal bovine serum processed to remove bovine exosomes, preventing contamination in MSC culture media. |

| SYBR Green PCR Master Mix | A fluorescent dye for qPCR that binds double-stranded DNA, used as an alternative to TaqMan probes for miRNA quantification. |

| Stem-loop RT Primers | Specialized reverse transcription primers that create a longer cDNA template from the short mature miRNA sequence for qPCR. |

| PBS (pH 7.4) | Phosphate-buffered saline for washing cell pellets, resuspending exosomes, and as a diluent for various reagents. |

| RNase Zap / RNase-free reagents | Critical for preventing degradation of low-abundance miRNA molecules during all steps of RNA work. |

Frequently Asked Questions (FAQs)

Q1: What is the primary goal of preconditioning MSCs for exosome production? A1: The primary goal is to modulate the MSC secretome, enhancing the yield, altering the cargo, and boosting the therapeutic efficacy (e.g., anti-inflammatory, pro-angiogenic) of the harvested exosomes for downstream applications.

Q2: What is the recommended duration for hypoxia preconditioning? A2: Most protocols use a duration between 24 and 72 hours. The optimal time can vary based on MSC source and desired exosome profile. Shorter times (24-48h) are common for inducing pro-angiogenic factors, while longer times may increase stress-related markers.

Q3: What are the critical quality control checkpoints after preconditioning? A3:

- Cell Viability: Confirm >90% viability via Trypan Blue exclusion or similar.

- Phenotypic Stability: Verify retention of MSC surface markers (CD73, CD90, CD105) and absence of hematopoietic markers via flow cytometry.

- Exosome Characterization: Validate exosome identity using NTA (for size/concentration), TEM (for morphology), and Western Blot (for markers like CD63, CD81, TSG101).

Q4: How do I choose between LPS and cytokine (TNF-α/IL-1β) preconditioning? A4: The choice depends on the intended therapeutic outcome.

- LPS: Mimics a bacterial infection, strongly polarizing MSCs towards an anti-inflammatory, immunomodulatory phenotype. Ideal for applications in sepsis or combating excessive inflammation.

- Cytokines (TNF-α/IL-1β): Mimic a sterile inflammatory environment (e.g., arthritis). This often leads to a more complex secretome with a mix of immunomodulatory and tissue-reparative factors.

Q5: Can preconditioning strategies be combined? A5: Yes, sequential combination is an active area of research. For example, priming with a cytokine followed by hypoxia can have a synergistic effect, potentially further enhancing exosome potency. However, this requires extensive optimization to avoid inducing senescence or apoptosis.

Troubleshooting Guide

Problem: Low Exosome Yield After Preconditioning

- Cause 1: Preconditioning stress-induced MSC senescence or apoptosis.

- Solution: Reduce the preconditioning stimulus concentration or duration. Perform a dose-response and time-course experiment to find the sub-toxic "sweet spot."

- Cause 2: Inefficient exosome isolation method.

- Solution: Compare ultracentrifugation with commercial polymer-based precipitation kits or size-exclusion chromatography. Ensure the protocol is optimized for your conditioned media volume.

Problem: High Levels of Contaminating Proteins in Exosome Prep

- Cause: Co-isolation of non-exosomal proteins and aggregates, common with precipitation kits.

- Solution: Incorporate a purification step, such as size-exclusion chromatography, after the initial isolation. Always include a PBS wash step during ultracentrifugation.

Problem: Inconsistent Results Between Batches

- Cause 1: Variability in MSC population (donor-to-donor, passage number).

- Solution: Use low-passage MSCs (P4-P8), fully characterize master cell banks, and use cells from a consistent donor source when possible.

- Cause 2: Inconsistent preconditioning environment.

- Solution: For hypoxia, use a dedicated, calibrated tri-gas incubator. For reagents, use aliquots from the same batch, and confirm LPS/cytokine activity with a reference assay (e.g., NF-κB reporter assay).

Problem: Preconditioning Induces Unwanted MSC Differentiation

- Cause: Specific stimuli (e.g., prolonged inflammatory signaling) may inadvertently trigger lineage commitment.

- Solution: After preconditioning and before exosome harvest, assess differentiation potential by staining for key lineage markers (e.g., Oil Red O for adipogenesis, Alizarin Red for osteogenesis).

Table 1: Impact of Preconditioning on MSC Exosome Characteristics

| Preconditioning Stimulus | Typical Concentration / Level | Key Cargo Changes (Example Proteins/miRNAs) | Reported Fold-Change in Yield | Primary Functional Outcome |

|---|---|---|---|---|

| Hypoxia (1-3% O₂) | 24 - 72 hours | ↑ miR-21, miR-31, miR-125b; ↑ VEGF, HIF-1α | 1.5 - 3.0x | Enhanced Angiogenesis, Cell Survival |

| LPS | 100 ng/mL - 1 µg/mL (24h) | ↑ miR-146a, let-7b; ↑ PGE2, IDO, TSG-6 | 1.2 - 2.0x | Potent Anti-inflammatory, Immunomodulation |

| TNF-α | 10 - 50 ng/mL (24-48h) | ↑ miR-146a, miR-155; ↑ IL-10, GRO-α | 1.5 - 2.5x | Enhanced Immunomodulation, Tissue Repair |

| IL-1β | 10 - 20 ng/mL (24-48h) | ↑ miR-146a, miR-21; ↑ IL-6, IL-8 | 1.3 - 2.0x | Enhanced Anti-inflammatory, Matrix Remodeling |

Experimental Protocols

Protocol 1: Hypoxia Preconditioning of MSCs for Exosome Production

- Cell Preparation: Seed MSCs at 70-80% confluence in complete growth medium.

- Adherence: Allow cells to adhere for 24 hours in a standard incubator (37°C, 5% CO₂, 21% O₂).

- Preconditioning:

- Replace medium with fresh, exosome-depleted (via ultracentrifugation or commercial kits) growth medium.

- Transfer culture flasks/plates to a pre-equilibrated hypoxia chamber or tri-gas incubator set to 37°C, 5% CO₂, and 1% O₂.

- Incubate for 48 hours.

- Conditioned Media Collection:

- Post-incubation, collect the conditioned media.

- Centrifuge at 300 × g for 10 min to remove cells.

- Centrifuge the supernatant at 2,000 × g for 20 min to remove dead cells and debris.

- Centrifuge again at 10,000 × g for 30 min to remove larger vesicles.

- The resulting supernatant is ready for exosome isolation (e.g., ultracentrifugation at 100,000 × g for 70 min).

Protocol 2: Inflammatory Preconditioning with TNF-α and IL-1β

- Cell Preparation: Seed MSCs as in Protocol 1.

- Stimulus Preparation: Reconstitute recombinant human TNF-α and IL-1β as per manufacturer's instructions. Prepare a working stock in PBS with 0.1% BSA.

- Preconditioning:

- Replace medium with fresh, exosome-depleted growth medium.

- Add TNF-α to a final concentration of 20 ng/mL and IL-1β to a final concentration of 10 ng/mL.

- Return cells to the standard incubator (37°C, 5% CO₂, 21% O₂) for 24 hours.

- Conditioned Media Collection: Follow the same centrifugation steps as in Protocol 1, Step 4.

Signaling Pathways and Workflows

Hypoxia Signaling in MSCs

Inflammatory Preconditioning Pathway

MSC Exosome Production Workflow

The Scientist's Toolkit

Table 2: Essential Research Reagents and Materials

| Item | Function / Application |

|---|---|

| Tri-Gas Incubator | Precise control of O₂, CO₂, and temperature for reliable hypoxia studies. |

| Recombinant Human TNF-α & IL-1β | High-purity, bioactive cytokines for inflammatory preconditioning. |

| Ultra-Low Attachment Flasks/Plates | To culture MSCs in suspension (e.g., as spheroids) which can synergize with preconditioning. |

| Exosome-Depleted FBS | Fetal Bovine Serum processed to remove bovine exosomes, preventing contamination of MSC-exosome preps. |

| Differential Ultracentrifuge | The gold-standard method for isolating exosomes via high-speed pelleting. |

| Nanoparticle Tracking Analysis (NTA) | Instrumentation to determine exosome particle size and concentration. |

| CD63/CD81/TSG101 Antibodies | Antibodies for Western Blot validation of exosome markers. |

| Annexin V / Propidium Iodide | Reagents for flow cytometry-based assessment of apoptosis/necrosis post-preconditioning. |

Impact of Preconditioning on Exosomal miRNA Profiles and Subsequent Immunomodulatory and Regenerative Outcomes

Troubleshooting Guide: Common Experimental Challenges

1. Problem: Low exosome yield after MSC preconditioning.

- Potential Causes: Suboptimal preconditioning agent concentration; insufficient stimulation duration; decline in MSC health.

- Solutions:

- Conduct a dose-response experiment for the preconditioning agent (e.g., test LPS at 0.1, 0.5, and 1.0 μg/mL) [9].

- Ensure MSCs are at 70-80% confluence at the start of preconditioning and are in a healthy, proliferative state [10].

- Standardize the duration of preconditioning; a common effective timeframe is 48 hours [10].

2. Problem: Inconsistent miRNA profiles in exosomes between batches.

- Potential Causes: Variability in MSC sources/passages; differences in exosome isolation methods; contamination of isolates.

- Solutions:

- Use MSCs at low, consistent passages (e.g., 3rd to 5th) and characterize them regularly for surface markers and viability [10] [11].

- Strictly adhere to a single, validated exosome isolation protocol (e.g., differential ultracentrifugation) across all experiments [10] [12].

- Include a size-exclusion chromatography (SEC) step post-isolation to remove contaminating proteins [12].

3. Problem: Isolated exosomes lack functional effects in recipient cells.

- Potential Causes: Exosome degradation due to improper storage; inefficient uptake by recipient cells; inaccurate exosome quantification.

- Solutions:

- Store exosomes in PBS with 0.1% BSA at -80°C and avoid repeated freeze-thaw cycles [13].

- Verify exosome uptake by labeling them with a lipophilic dye (e.g., DiI) and visualizing with confocal microscopy [10].

- Quantify exosomes using nanoparticle tracking analysis (NTA) rather than relying solely on protein concentration, which can be inaccurate [10] [13].

4. Problem: Poor targeting of exosomes to specific cell types.

- Potential Causes: Native exosomes lack tissue-specific tropism.

- Solutions:

Frequently Asked Questions (FAQs)

Q1: What are the most effective preconditioning strategies to enhance immunomodulatory miRNA content? Preconditioning MSCs with inflammatory cytokines is highly effective. Key strategies and their resulting miRNAs include:

- IFN-γ: Upregulates miR-21, which improves cardiac function post-infarction via the STAT1/miR-21/BTG2 axis [15].

- IL-1β: Increases miR-146a and miR-21 levels, promoting anti-inflammatory M2 macrophage polarization [15] [9].

- TNF-α: Upregulates miR-146a in a dose-dependent manner, enhancing immunomodulatory potential [9].

- LPS: At 1 μg/mL, significantly increases miR-150-5p, which modulates macrophage plasticity via the PI3K/Akt/mTOR pathway [10].

Q2: How does hypoxic preconditioning alter the exosomal miRNA profile for regenerative outcomes? Hypoxic preconditioning (typically 1-5% O₂) mimics the physiological niche and robustly enhances pro-angiogenic and pro-regenerative miRNA content [15]:

- It upregulates miR-612 and miR-486-5p, stimulating HIF-1α-VEGF signaling and promoting angiogenesis [15].

- It enriches miR-125a-5p, which protects vascular endothelial cells and blood-brain barrier integrity by targeting RTEF-1 under hypoxic stress [16].

Q3: What is the best method for isolating exosomes for miRNA profiling? No single method is perfect, and the choice can impact miRNA profiles [12]. The most common and reliable method is differential ultracentrifugation [10] [12]. However, it can co-isolate contaminants. For higher purity, especially from complex biofluids like plasma, following ultracentrifugation with size-exclusion chromatography (SEC) is recommended to remove soluble proteins and improve the accuracy of downstream miRNA analysis [12] [13].

Q4: Are there specific markers to confirm the successful isolation of MSC-derived exosomes? No single universal marker exists. The International Society for Extracellular Vesicles (ISEV) recommends a combination of positive and negative markers [13] [14]:

- Positive Markers: Tetraspanins (CD9, CD63, CD81), TSG101, and Alix. Always check for multiple markers, as some MSC exosomes may be negative for one (e.g., CD9 in some cell lines) [13].

- Negative Markers: Assess for the absence of organelle-specific contaminants, such as calnexin (ER), GM130 (Golgi), or histones (nucleus) [13].

Q5: How can we functionally validate the role of a specific miRNA in exosome-mediated effects? A standard workflow involves:

- Identification: Use miRNA sequencing to identify differentially expressed miRNAs in your preconditioned exosomes [10] [9].

- Gain-of-function: Transfert parent MSCs with mimics of the target miRNA, isolate exosomes, and test their enhanced function in vitro [14].

- Loss-of-function: Treat recipient cells with an inhibitor (antagomir) of the target miRNA before adding the preconditioned exosomes. A rescue of the functional effect confirms the miRNA's role [10].

- Mechanism: Use luciferase reporter assays to validate direct binding of the miRNA to its putative mRNA target (e.g., miR-150-5p targeting Irs1) [10].

Table 1: Preconditioning Agents and Their Impact on Key Exosomal miRNAs

| Preconditioning Agent | Key Upregulated miRNA(s) | Validated Target/Pathway | Primary Functional Outcome | Citation |

|---|---|---|---|---|

| LPS (1 μg/mL) | miR-150-5p | Irs1; PI3K/Akt/mTOR pathway | Promotes M2 macrophage polarization, improves sepsis survival | [10] |

| Hypoxia (1-5% O₂) | miR-125a-5p, miR-612, miR-486-5p | RTEF-1/VEGF, HIF-1α-VEGF, MMP19 | Enhances angiogenesis, protects endothelial function, repairs infarcted myocardium | [15] [16] |

| IFN-γ | miR-21 | STAT1/BTG2 signaling axis | Improves cardiac function post-myocardial infarction, suppresses apoptosis | [15] |

| IL-1β | miR-21, miR-146a | PDCD4, NF-κB signaling | Induces M2 macrophage polarization, alleviates sepsis | [15] [9] |

| TNF-α (10-20 ng/mL) | miR-146a | NF-κB signaling | Enhances immunomodulatory capacity, promotes macrophage polarization | [9] |

| MIF | miR-133a-3p | AKT signaling pathway | Enhances angiogenesis, inhibits cardiomyocyte apoptosis, improves cardiac function | [15] |

| Atorvastatin (ATV) | miR-221-3p | AKT/eNOS pathway | Promotes wound healing and angiogenesis in diabetic rats | [15] |

Table 2: Essential Research Reagent Solutions

| Reagent / Tool | Primary Function | Example Application | Citation |

|---|---|---|---|

| Dynabeads (CD9/CD63/CD81) | Immunocapture of specific exosome subpopulations | Isolating exosomes directly from cell culture media or pre-enriched samples for downstream analysis. | [13] |

| Adenoviral Transfection System | Genetic modification of parent MSCs | Overexpressing genes (e.g., Akt) or specific miRNAs to engineer exosome cargo. | [15] |

| miRNA Mimics and Inhibitors | Functional validation of exosomal miRNAs | Confirming the role of a specific miRNA (e.g., miR-150-5p) in recipient cell effects. | [10] [14] |

| Size-Exclusion Chromatography (SEC) Columns | High-purity exosome isolation | Removing contaminating proteins from plasma or serum samples prior to miRNA profiling. | [12] [13] |

| Lipopolysaccharide (LPS) | Preconditioning agent | Priming MSCs to enhance the immunomodulatory miRNA content of their exosomes. | [10] [9] |

| CD9/CD63/CD81 Antibodies | Exosome characterization (Western Blot/Flow) | Verifying the presence of exosome markers and confirming successful isolation. | [13] |

Detailed Experimental Protocols

Protocol 1: LPS Preconditioning and Exosome Isolation for Immunomodulation Studies [10]

- Cell Culture: Grow adipose-derived MSCs (or other MSC types) in DMEM/F12 with 10% exosome-depleted FBS to ~70-80% confluence.

- Preconditioning: Replace medium with fresh medium containing 1 μg/mL LPS (from E. coli or similar). Incubate for 48 hours. Include a control with PBS.

- Supernatant Collection: Collect conditioned medium. Centrifuge at 350 × g for 10 min (remove cells), then at 2,000 × g for 10 min (remove debris), and finally at 10,000 × g for 30 min (remove microvesicles/apoptotic bodies).

- Exosome Isolation (Ultracentrifugation): Filter the supernatant through a 0.22 μm filter. Ultracentrifuge at 120,000 × g for 70 minutes at 4°C.

- Washing: Discard supernatant, resuspend the pellet in a large volume of PBS, and repeat ultracentrifugation (120,000 × g, 70 minutes).

- Resuspension: Resuspend the final exosome pellet in PBS and store at -80°C.

- Characterization: Validate exosomes using NTA (size/concentration), TEM (morphology), and Western blot for CD9, CD63, and TSG101.

Protocol 2: Functional Validation of Exosomal miRNA in Macrophage Polarization [10]

- Differentiate BMDMs: Isolate bone marrow cells from mice and culture them for 7 days in DMEM with 10% FBS and 10 ng/mL M-CSF to generate bone marrow-derived macrophages (BMDMs).

- Stimulate and Treat: Stimulate BMDMs with LPS (1 μg/mL) to induce an inflammatory (M1) state. Co-treat with isolated exosomes (e.g., LPS-Exo vs. control Exo, ~50-100 μg/mL total protein).

- Inhibition Assay: To confirm the role of a specific miRNA, pre-treat BMDMs with a miRNA inhibitor (e.g., anti-miR-150-5p) before adding the exosomes.

- Analysis:

- Flow Cytometry: Analyze for M2 markers (e.g., CD206) 24-48 hours post-treatment.

- qPCR: Measure expression of M2 genes (Arg1, Mrc1) and pro-inflammatory cytokines (TNF-α, IL-6).

- ELISA: Quantify secretion of anti-inflammatory cytokines like IL-10.

Signaling Pathway Diagrams

Diagram 1: LPS-preconditioned exosomes promote M2 macrophage polarization via the miR-150-5p/Irs1/PI3K/Akt/mTOR axis. This pathway illustrates how exosomal miR-150-5p derived from LPS-preconditioned MSCs inhibits Irs1 in recipient macrophages, leading to downregulation of the PI3K/Akt/mTOR pathway and subsequent promotion of anti-inflammatory M2 macrophage polarization [10].

Diagram 2: Hypoxia-preconditioned exosomes mediate endothelial protection via the miR-125a-5p/RTEF-1 axis. This pathway shows how hypoxia preconditioning enriches miR-125a-5p in MSC exosomes (H-EXO), which upon delivery to endothelial cells inhibits RTEF-1, leading to reduced pathological VEGF expression and resulting in protection of the blood-brain barrier and attenuation of hypoxic injury [16].

Technical Support Center: Troubleshooting & FAQs

FAQ 1: Why is my Western Blot for CD63/CD9 showing weak or no signal despite high exosome protein yield?

A: This is a common issue when scaling MSC cultures. The problem often lies in sample preparation or loading.

- Cause 1: Protease Degradation. Extended culture times or inefficient purification can expose exosomes to proteases.

- Solution: Always include fresh protease inhibitors during and after purification. Process samples quickly and store at -80°C.

- Cause 2: Overloading of PVDF Membrane. Too much protein can prevent proper transfer and binding.

- Solution: Titrate your protein load. Start with 5-20 µg of exosomal protein. Use a Ponceau S stain post-transfer to visualize total protein and confirm successful transfer.

- Cause 3: Antibody Incompatibility. The epitope recognized by the antibody might be masked due to the exosome's lipid bilayer conformation.

- Solution: Add a detergent (e.g., 0.1% SDS) to your loading buffer and denature samples at 95°C for 5-10 minutes. This can expose hidden epitopes for CD9 and CD63.

FAQ 2: My NTA results show a high particle count but a large size distribution (>200 nm). What does this indicate?

A: A broad size distribution, especially with peaks above 200nm, suggests the presence of non-exosomal particles or aggregation.

- Cause 1: Cell Debris and Apoptotic Bodies. Scaling up MSC cultures can lead to increased cell death.

- Solution: Optimize your purification. Introduce a density gradient centrifugation step (e.g., iodixanol gradient) after ultracentrifugation to separate exosomes from protein aggregates and other vesicles.

- Cause 2: Exosome Aggregation. Exosomes can aggregate during storage or processing.

- Solution: Always resuspend the final exosome pellet in a filtered PBS solution (e.g., with 0.1-1.0 µm filter) and vortex thoroughly. Avoid multiple freeze-thaw cycles. Perform NTA immediately after resuspension.

- Cause 3: Protein Contamination. Soluble proteins can co-pellet and be counted as particles.

- Solution: Include a wash step with a large volume of PBS during ultracentrifugation.

FAQ 3: TEM confirms vesicle structures, but they appear empty or ruptured. Is this normal?

A: This is often an artifact of the sample preparation technique, not the native state of the exosomes.

- Cause 1: Negative Staining Artifact. Over-staining or improper drying can cause structural collapse.

- Solution: Ensure the staining solution (e.g., Uranyl Acetate) is fresh and properly filtered. Apply the stain for a shorter duration (30-60 seconds) and allow the grid to air-dry completely in a dust-free environment.

- Cause 2: Hypertonic Stress. The high salt concentration of phosphotungstic acid can dehydrate and shrink vesicles.

- Solution: Use Uranyl Acetate as it is generally gentler. Alternatively, use cryo-TEM for a true native-state visualization without staining artifacts.

FAQ 4: TSG101 appears as a doublet or smeared band in Western Blot. Why?

A: TSG101 is susceptible to degradation and can exhibit multiple isoforms.

- Cause 1: Protein Degradation.

- Solution: As with FAQ 1, ensure a robust protease inhibitor cocktail is used. Freshly prepare all samples.

- Cause 2: Alternative Splicing/Glycosylation. TSG101 can undergo post-translational modifications.

- Solution: This may be biological. Run a positive control (e.g., cell lysate from HEK293 cells) alongside your exosome samples to confirm the antibody's specificity and expected band pattern.

Table 1: Expected Size and Concentration Ranges for MSC-Derived Exosomes

| Characterization Technique | Expected Typical Range | Notes for Scaled Production |

|---|---|---|

| Nanoparticle Tracking Analysis (NTA) | Size: 80 - 150 nmConcentration: 1e8 - 5e10 particles/mL (culture supernatant) | Concentration is highly dependent on MSC source (e.g., bone marrow, adipose), passage number, and culture conditions. Serum-free media often yields lower concentrations than FBS-depleted media. |

| Transmission Electron Microscopy (TEM) | Morphology: Cup-shaped, bilayered vesicles | Aggregation or irregular shapes may indicate stress during culture or processing. |

Table 2: Expected Western Blot Results for Essential Markers

| Marker | Expected Band Size (kDa) | Localization | Notes |

|---|---|---|---|

| CD9 | ~24-27 kDa | Transmembrane | May appear as a broad band due to glycosylation. |

| CD63 | ~50-60 kDa | Transmembrane | Highly glycosylated; can show a diffuse band. |

| TSG101 | ~44 kDa | Cytosolic (intraluminal) | A key component of the ESCRT-I complex. Degradation can produce a ~36 kDa fragment. |

Experimental Protocols

Protocol 1: Exosome Isolation via Differential Ultracentrifugation for Scaled MSC Cultures

- Conditioned Media Collection: Culture MSCs in multi-layered flasks or a bioreactor. Collect conditioned media after 48-72 hours.

- Centrifugation: Centrifuge at 300 × g for 10 min to remove cells.

- Supernatant Transfer: Transfer supernatant to new tubes. Centrifuge at 2,000 × g for 20 min to remove dead cells.

- Second Supernatant Transfer: Transfer supernatant to ultracentrifuge tubes. Centrifuge at 10,000 × g for 30 min to remove cell debris.

- Final Supernatant & Ultracentrifugation: Transfer the supernatant to fresh ultracentrifuge tubes. Centrifuge at 100,000 × g for 70 min at 4°C.

- Wash: Resuspend the pellet in a large volume of PBS. Centrifuge again at 100,000 × g for 70 min.

- Resuspension: Resuspend the final, clean exosome pellet in 50-200 µL of PBS. Aliquot and store at -80°C.

Protocol 2: Western Blot for Exosomal Markers (CD9, CD63, TSG101)

- Protein Quantification: Determine exosome protein concentration using a BCA or Micro BCA assay.

- Sample Preparation: Mix 10-20 µg of exosomal protein with 4X Laemmli buffer (with 10% β-mercaptoethanol). Denature at 95°C for 5-10 min.

- Gel Electrophoresis: Load samples onto a 4-20% gradient SDS-PAGE gel. Run at 120 V for ~90 min.

- Transfer: Transfer proteins to a PVDF membrane using a wet transfer system at 100 V for 60-70 min on ice.

- Blocking: Block membrane with 5% non-fat milk in TBST for 1 hour at room temperature.

- Primary Antibody Incubation: Incubate with primary antibodies (e.g., anti-CD9, anti-CD63, anti-TSG101) diluted in 5% BSA/TBST overnight at 4°C.

- Washing & Secondary Incubation: Wash membrane 3x with TBST. Incubate with HRP-conjugated secondary antibody for 1 hour at room temperature.

- Detection: Wash membrane 3x with TBST. Apply ECL substrate and image with a chemiluminescence detector.

Visualizations

Diagram 1: MSC Exosome QC Workflow

Diagram 2: Exosome Biogenesis & Key Markers

The Scientist's Toolkit

Table 3: Essential Research Reagents for Exosome QC

| Reagent / Material | Function | Example / Note |

|---|---|---|

| Differential Ultracentrifuge | Isolates exosomes from conditioned media based on size and density. | Critical for pellet purity. Ensure proper rotor calibration. |

| NTA System (e.g., NanoSight) | Measures particle size distribution and concentration in liquid suspension. | Provides quantitative data essential for dosing in therapeutic applications. |

| Transmission Electron Microscope | Provides high-resolution images to confirm vesicle morphology and bilayer structure. | Cryo-TEM is the gold standard for visualizing native state. |

| Anti-CD9 / CD63 / TSG101 Antibodies | Detect specific exosomal surface and intraluminal proteins via Western Blot or Flow Cytometry. | Validate antibodies for exosome detection, as glycosylation can affect binding. |

| Protease Inhibitor Cocktail | Prevents degradation of exosomal proteins and markers during isolation and storage. | Must be added to all buffers post-cell removal. |

| Iodixanol (OptiPrep) | Used for density gradient ultracentrifugation to achieve high-purity exosome preparations. | Separates exosomes from contaminants like protein aggregates. |

| PVDF Membrane | Used for Western Blotting; binds proteins efficiently for antibody probing. | Pre-wet in 100% methanol before use. |

Advanced Bioprocessing: From 2D Flasks to Industrial Bioreactors

Comparative Analysis of 2D vs. 3D Culture Systems for Scalability and Exosome Yield

The transition of mesenchymal stem cell-derived exosomes from promising research entities to mainstream therapeutic agents is critically dependent on solving the challenge of scalable production. While conventional two-dimensional (2D) culture has been the workhorse of cell biology for decades, its limitations in mimicking the natural cellular microenvironment and producing sufficient exosome yields are increasingly apparent. Three-dimensional (3D) culture systems have emerged as a powerful alternative that better recapitulates in vivo conditions, but each approach presents distinct advantages and challenges for researchers aiming to scale up exosome production. This technical support center provides a comprehensive comparison of these systems, with practical troubleshooting guidance and experimental protocols to optimize your MSC culture conditions for maximal exosome yield while maintaining therapeutic potency.

Quantitative Comparison: 2D vs. 3D Culture Systems

Performance Metrics for Scalability and Yield

Table 1: Quantitative comparison of exosome production between 2D and 3D culture systems

| Performance Metric | 2D Culture System | 3D Culture System | Improvement Factor | References |

|---|---|---|---|---|

| Exosome Yield | Baseline | 19.4-fold increase | 19.4× | [17] |

| Particle Production | Baseline | 20-fold increase (3D-UC); 140-fold increase (3D-TFF) | 20-140× | [18] |

| Cell Proliferation | Baseline | ~2-fold higher in Bio-Block systems | ~2× | [19] |

| Senescence Reduction | Baseline | 30-37% reduction | 1.3-1.37× | [19] |

| Apoptosis Reduction | Baseline | 2-3-fold decrease | 2-3× | [19] |

| Secretion Dynamics | Declines after confluence | Increases as cells approach confluency in 3D | Significant trend reversal | [20] |

| Therapeutic Efficacy | Moderate protection in AKI model | Enhanced protection in AKI model | Significantly superior | [17] |

System Characteristics and Implementation Considerations

Table 2: Characteristics of different 3D culture systems for MSC exosome production

| System Type | Key Features | Exosome Yield Advantage | Implementation Complexity | Therapeutic Potency Evidence | |

|---|---|---|---|---|---|

| Hollow Fiber Bioreactor | 20mL volume, 3000cm² surface area, polysulfone fibers | 19.4-fold increase, more concentrated supernatants (15.5-fold) | High - requires specialized equipment | Superior efficacy in AKI model, improved cellular uptake | [17] |

| Microcarrier-Based | Doubles cell density (40,000 cells/cm²), compatible with bioreactors | 20-fold increase with UC, 140-fold with TFF | Medium - requires microcarrier handling | 7-fold more potent in siRNA transfer to neurons | [18] |

| Hydrogel-Based (Bio-Block) | Biomimetic platform, preserves stem-like properties | EV production increased ~44% while other systems decline | Medium - hydrogel handling required | Enhanced EC proliferation, migration, and VE-cadherin expression | [19] |

| Spheroid Suspension | Simple setup, no scaffolds, better cell-cell interactions | Increased secretion rate compared to 2D | Low - easiest 3D implementation | Altered proteomic cargo, differential recipient cell response | [21] |

Experimental Protocols for Scalable Exosome Production

Hollow Fiber Bioreactor 3D Culture Protocol

Objective: Establish a scalable 3D culture system for enhanced exosome production using hollow fiber bioreactor technology.

Materials Required:

- FiberCell System C2011 or equivalent hollow fiber bioreactor

- Hydrophilic polysulfone hollow fibers (200μm internal diameter, 20kDa MWCO)

- Pulsatile perfusion pump and oxygenator

- Mesenchymal stem cells (2×10⁸ cells)

- Serum-free culture media

- Glucose monitoring system

Methodology:

- System Preparation: Condition internal and external spaces of the hollow fiber bioreactor with PBS or culture media for 24 hours circulation.

- Cell Seeding: Resuspend 2×10⁸ MSCs in 15mL suspension and inoculate into the external space of the 3D culture system.

- Culture Maintenance: Maintain culture media flow through internal space at 22-28 pulses per minute.

- Media Monitoring: Monitor glucose concentration in culture medium every 12 hours; replace when concentration drops by 50%.

- Exosome Collection: Collect serum-free supernatants from external space regularly for exosome isolation.

- Quality Control: Verify MSC surface markers (CD29, CD44, CD73, CD90) and trilineage differentiation potential post-culture.

Expected Outcomes: This protocol typically yields 19.4-fold higher exosome production compared to conventional 2D culture, with more concentrated supernatants (15.5-fold) leading to higher collection efficiency [17].

Combined 3D Culture with Tangential Flow Filtration Protocol

Objective: Maximize exosome yield and purity through integration of 3D culture with advanced isolation techniques.

Materials Required:

- Microcarrier-based 3D culture system

- Tangential Flow Filtration system

- Ultracentrifugation equipment

- Transmission electron microscope for characterization

- Nanoparticle tracking analysis system

- Western blot equipment for exosome markers (CD9, CD63, CD81, TSG101)

Methodology:

- 3D Cell Culture: Establish microcarrier-based 3D cultures of umbilical cord-derived MSCs (optimal source for exosome yield).

- Conditioned Media Collection: Collect conditioned media from 3D cultures at optimal density points.

- Primary Concentration: Use Tangential Flow Filtration for initial concentration and buffer exchange.

- Exosome Isolation: Apply TFF for final isolation (superior to ultracentrifugation for yield).

- Characterization: Validate exosomes through TEM (cup-shaped morphology), NTA (size distribution 30-150nm), and western blot (positive for CD9, CD63, CD81, TSG101; negative for calnexin).

- Potency Testing: Assess biological activity through siRNA transfer efficiency or endothelial cell functional assays.

Expected Outcomes: The combined approach of 3D culture with TFF isolation can yield 140-fold more exosomes than conventional 2D culture with ultracentrifugation, with 7-fold greater potency in functional assays [18].

Troubleshooting Guides and FAQs

Common Experimental Challenges and Solutions

Table 3: Troubleshooting guide for 3D culture systems in exosome production

| Problem | Potential Causes | Solutions | Preventive Measures | |

|---|---|---|---|---|

| Low exosome yield in 3D systems | Suboptimal cell density, inadequate nutrient supply, improper scaffold selection | Monitor glucose consumption as indicator of metabolic activity; adjust cell seeding density; ensure proper media flow in perfusion systems | Pre-optimize cell seeding density in small-scale trials; use glucose monitoring as proxy for cell health | [17] |

| Reduced exosome functionality | Cellular senescence, improper differentiation, suboptimal culture duration | Implement shorter culture cycles; monitor senescence markers; use early passage cells (P2-P6) | Regular assessment of stem cell markers and differentiation potential; limit passage number | [19] [17] |

| Inconsistent results between batches | MSC source variability, serum lot variations, protocol deviations | Standardize MSC sources (umbilical cord shows highest yield); use defined serum-free media; implement rigorous QC protocols | Bank early passage cells; use standardized, characterized media components; maintain detailed culture records | [18] [5] |

| Difficulty in exosome purification | Co-isolation of protein aggregates, media components contamination | Implement TFF instead of UC; combine isolation methods; optimize filtration parameters | Use serum-free media during collection; pre-clear conditioned media; validate with multiple characterization methods | [18] [5] |

| Poor scalability | Limited surface area, inadequate gas exchange, nutrient gradients | Transition to bioreactor systems; implement perfusion culture; optimize oxygen delivery | Start with scalable systems like hollow fiber bioreactors; design scale-up strategy early | [17] [6] |

Frequently Asked Questions

Q1: What is the optimal MSC source for maximizing exosome yield in 3D culture systems?

A: Umbilical cord-derived MSCs, particularly from Wharton's jelly, demonstrate superior exosome yield compared to bone marrow or adipose tissue sources. They exhibit faster doubling times (~4 days vs ~7 days) and produce four times more exosomes per cell. Exosomes from umbilical cord MSCs are also larger (140±18nm) which may influence cargo capacity [18].

Q2: How much can I realistically expect to increase exosome yield by switching from 2D to 3D culture?

A: The increase is substantial and system-dependent. Hollow fiber bioreactors can provide 19.4-fold higher yields [17], while microcarrier-based 3D culture combined with tangential flow filtration can yield 140-fold more exosomes compared to traditional 2D culture with ultracentrifugation [18]. The greatest improvements are seen when both culture and isolation methods are optimized together.

Q3: Does 3D culture affect the therapeutic potency of MSC-derived exosomes, or just the quantity?

A: Evidence indicates that 3D culture enhances both quantity and quality. Exosomes from 3D cultures demonstrate superior therapeutic efficacy in disease models like acute kidney injury, show enhanced cellular uptake, and contain different molecular cargoes that may better mimic in vivo conditions [17] [20]. The 3D environment appears to influence exosome composition and function beyond simply increasing yield.

Q4: What are the critical quality control checkpoints when implementing 3D culture for exosome production?

A: Essential QC measures include: (1) Verification of MSC surface markers (CD73, CD90, CD105 positive; CD34, CD45 negative) post-culture [17], (2) Assessment of trilineage differentiation potential [17], (3) Exosome characterization through TEM (morphology), NTA (size and concentration), and western blot for markers (CD9, CD63, CD81, TSG101) [18] [5], (4) Functional potency assays relevant to your therapeutic application [19] [17].

Q5: How does the choice of isolation method impact exosome yield and quality from 3D cultures?

A: Isolation method significantly affects both yield and quality. Tangential Flow Filtration (TFF) outperforms ultracentrifugation (UC) by providing 7-fold higher yields when processing 3D culture conditioned media [18] [5]. TFF also better preserves exosome functionality and is more scalable for clinical-grade production. The combination of 3D culture with TFF represents the current state-of-the-art for scalable exosome production.

Visual Experimental Workflows

3D Culture and Exosome Isolation Workflow

Decision Framework for Culture System Selection

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 4: Key research reagents and materials for optimized MSC exosome production

| Reagent/Material | Function/Purpose | Examples/Specifications | Performance Notes |

|---|---|---|---|

| Hollow Fiber Bioreactor | Scalable 3D culture platform | FiberCell System C2011; Polysulfone fibers (200μm diameter, 20kDa MWCO) | Provides 19.4-fold yield increase; enables continuous production [17] |

| Microcarriers | 3D substrate for cell growth in suspension | Various compositions (plastic, glass, gelatin); size-adjusted for specific systems | Doubles cell density compared to 2D (40,000 vs 20,000 cells/cm²) [18] |

| Hydrogel Scaffolds | Biomimetic 3D microenvironment | Peptide hydrogels, Matrigel, Bio-Block platform | Preserves stem cell properties, enhances therapeutic cargo [19] [20] |

| Tangential Flow Filtration | Scalable exosome isolation | Systems with appropriate molecular weight cutoffs | 7-fold higher yield than ultracentrifugation; maintains bioactivity [18] |

| Serum-Free Media | Cell culture without FBS contaminants | Commercially available MSC serum-free formulations | Eliminates bovine exosome contamination; improves downstream purification |

| Characterization Tools | Exosome validation and QC | NTA (size/concentration), TEM (morphology), Western Blot (markers) | Essential for quality control; CD9, CD63, CD81, TSG101 positive; calnexin negative [18] [5] |

| Glucose Monitoring | Metabolic activity assessment | Laboratory glucose assay kits | Indicator of cell health and optimization point for media changes [17] |

The evidence consistently demonstrates that 3D culture systems significantly outperform traditional 2D methods for scalable production of MSC-derived exosomes, with yield improvements ranging from 19 to 140-fold depending on the specific technologies employed. Beyond quantitative gains, 3D cultures generate exosomes with enhanced therapeutic properties that better mimic in vivo conditions. The most successful implementation strategies combine optimized 3D culture platforms with advanced isolation methods like tangential flow filtration, rigorous quality control measures, and careful attention to MSC source selection. As the field advances toward clinical translation, researchers should prioritize systems that balance scalability with therapeutic potency, ensuring that increased production volumes do not compromise biological activity.

Implementing Stirred-Tank and Hollow Fiber Bioreactors for Large-Scale Production

Frequently Asked Questions (FAQs)

Q1: What are the primary advantages of using a hollow fiber bioreactor over traditional 2D flasks for MSC exosome production? Hollow fiber bioreactors (HFBs) provide a three-dimensional perfusion environment that supports extremely high cell densities (often exceeding 10⁸ cells/mL) by mimicking in-vivo conditions [22]. This system allows for continuous production and harvest of exosomes from the same cell population over extended periods (up to 25 days or more) without subculturing [23] [24] [25]. Compared to 2D flask culture, this technology has been shown to increase total exosome yield by up to 19.4-fold and produces a more concentrated harvest, significantly simplifying downstream processing [25].

Q2: Can stirred-tank bioreactors be used for adherent MSC cultures, and if so, how? Yes, stirred-tank bioreactors (STRs) can effectively cultivate adherent MSCs by using microcarriers (MCs). Microcarriers are small particles suspended in the culture medium, providing a large surface area for cells to attach and grow [26]. Processes can be operated in repeated-batch or perfusion mode, the latter using cell retention devices like Alternating Tangential Flow (ATF) filtration to maintain high cell densities. These systems have achieved viable cell concentrations of approximately 2.9 × 10⁶ cells/mL in a 1.8 L scale process [26].

Q3: How does bioreactor culture affect the quality and functionality of the produced exosomes? Research indicates that exosomes produced from MSCs in both hollow fiber and microcarrier-based stirred-tank bioreactors retain their characteristic size, morphology, and surface marker expression (e.g., CD63, CD81, TSG101) [24] [25]. Importantly, these "3D-exosomes" are functionally competent. Studies have demonstrated that they exhibit comparable or even enhanced therapeutic efficacy in disease models, such as acute kidney injury and pulmonary fibrosis, when compared to exosomes derived from 2D flask cultures [27] [25].

Q4: What are the critical scaling-up challenges for MSC exosome production, and how can they be addressed? The main challenges include:

- Scalable Cell Source: Primary MSCs have limited expansion capacity. Potential solutions include using immortalized MSC lines (iMSCs) or induced MSCs (iMSCs) derived from pluripotent stem cells, which offer a renewable and consistent cell source [27] [24].

- Process Control: Maintaining optimal culture conditions (nutrients, waste, pH) is crucial. Perfusion-based systems (both hollow fiber and STR with ATF) enable better control and can support long-term cultures for continuous exosome harvest [23] [26].

- Downstream Processing: Large volumes of conditioned media require efficient exosome isolation. Integrating Tangential Flow Filtration (TFF) and other scalable purification methods is essential for processing harvests from bioreactors at clinical scale [28] [29].

Troubleshooting Guides

Table 1: Common Bioreactor Issues and Solutions

| Problem | Potential Causes | Recommended Solutions |

|---|---|---|

| Low Exosome Yield | - Low cell density or viability.- Suboptimal perfusion rate.- Exosome loss during harvest. | - Monitor glucose consumption/lactate production to infer cell number and health [30].- Ensure pore size (MWCO) is appropriate for exosome retention (e.g., 20-60 kDa membranes retain 30-150 nm exosomes) [22] [25].- Validate harvest frequency and volume to prevent over-concentration and shear stress [22]. |

| Rapid Pressure Increase in Hollow Fiber System | - Membrane fouling or clogging.- Cell overgrowth blocking fiber pores. | - Pre-filter culture media and supplements.- Implement a nuclease treatment step (e.g., with Kryptonase) to reduce chromatin contamination that can foul membranes [29].- Do not exceed recommended cell seeding density. |

| Poor Cell Attachment & Growth on Microcarriers in STR | - Inadequate microcarrier coating.- Improper initial agitation.- Suboptimal culture medium. | - Use coated microcarriers (e.g., Synthemax II-SC, collagen) to enhance cell attachment [26].- After seeding, use a low, intermittent agitation strategy to facilitate cell-particle contact before initiating continuous stirring [26].- Use EV-depleted platelet lysate or human platelet lysate (hPL) in media to support growth while reducing contaminating vesicles [28] [30]. |

| High Contaminant Levels in Isolated Exosomes | - Co-isolation of proteins and nucleic acids from cell culture debris.- Contaminants from culture supplements (e.g., FBS, PL). | - Employ a multi-step purification strategy: sequential TFF and Size-Exclusion Chromatography (SEC) or anion-exchange chromatography [28] [29].- Culture cells in xeno-free, serum-free, or EV-depleted media for 24-48 hours prior to conditioned media collection [28] [30]. |

Table 2: Key Performance Metrics for Bioreactor Systems

| Parameter | Hollow Fiber Bioreactor [23] [25] [30] | Stirred-Tank Bioreactor (with Microcarriers) [27] [26] |

|---|---|---|

| Typical Cell Density | > 10⁸ cells/mL (within fiber cartridge) | ≈ 2.9 × 10⁶ cells/mL (in suspension) |

| Production Duration | Up to 25+ days (continuous) | ~5-7 days (batch/perfusion) |

| Reported Exosome Yield Increase (vs. 2D) | Up to 19.4-fold | Information not explicitly quantified in search results, but systems are designed for high-yield production. |

| Key Advantage | High-yield, continuous production with integrated concentration. | Superior scalability and process monitoring. |

Experimental Protocols

Protocol 1: Setting Up a Hollow Fiber Bioreactor for MSC Exosome Production

This protocol is adapted from published studies for the production of MSC-derived exosomes over a sustained period [23] [25] [30].

Key Research Reagents:

- Hollow Fiber Bioreactor: FiberCell Systems or Quantum Cell Expansion System.

- Cells: Primary MSCs or immortalized MSCs (iMSCs).

- Coating Solution: Human fibronectin (e.g., 0.005% in PBS).

- Expansion Medium: α-MEM or commercial MSC medium, supplemented with FBS or human platelet lysate (hPL).

- Production Medium: Serum-free medium (SFM) or EV-depleted medium.

Methodology:

- System Preparation: Connect all components and circulate phosphate-buffered saline (PBS) through the system to prime it. Coat the hollow fibers by circulating a fibronectin solution for several hours, followed by a washout with culture medium [30].

- Cell Seeding: Expand MSCs in 2D flasks or CellSTACKs to generate sufficient biomass. Harvest cells and inoculate a high-density cell suspension (e.g., 2×10⁸ cells for a medium-sized cartridge) into the extracapillary space (ECS) of the bioreactor [25] [30].

- Expansion Phase: Initiate perfusion with expansion medium. Monitor cell growth indirectly by tracking metabolic markers like glucose consumption and lactate production. Increase the media perfusion rate as the cell density increases [30].

- Production Phase: Once target cell density is reached, switch to serum-free production medium to collect exosomes devoid of contaminating serum vesicles. Continue perfusion to supply nutrients [30].

- Continuous Harvest: Collect conditioned medium from the ECS daily or every other day. The hollow fibers' molecular weight cutoff (e.g., 20-60 kDa) retains exosomes (30-150 nm) within the ECS, resulting in a pre-concentrated harvest [22] [25]. The system can be maintained for several weeks with periodic harvests [23].

- Exosome Isolation: Clarify the harvested conditioned medium by low-speed centrifugation (2,000 × g for 20 min) to remove cell debris. Concentrate and purify exosomes using ultracentrifugation (100,000 × g for 2 hours) or scalable methods like Tangential Flow Filtration (TFF) [25] [30].

Protocol 2: MSC Expansion and Exosome Production in a Stirred-Tank Bioreactor

This protocol outlines a perfusion-based process for expanding MSCs on microcarriers in a stirred-tank bioreactor, a platform suitable for subsequent exosome production [26].

Key Research Reagents:

- Bioreactor: 1.8 L single-use stirred tank bioreactor.

- Cell Retention Device: Alternating Tangential Flow (ATF) system.

- Microcarriers: Synthemax II-SC or similar coated microcarriers.

- Cells: Immortalized hMSCs (e.g., ASC52telo line).

- Medium: Xeno-free MSC medium (e.g., Stemline XF).

Methodology:

- Bioreactor and Microcarrier Preparation: Hydrate and coat microcarriers according to the manufacturer's instructions. Sterilize the bioreactor and transfer the microcarrier slurry into the vessel with the cultivation medium [26].

- Cell Seeding: Seed cells directly into the bioreactor vessel. Use an intermittent agitation protocol (e.g., 5 minutes on, 30-60 minutes off) for the first several hours to promote homogeneous cell attachment to the microcarriers [26].

- Perfusion Cultivation: After the attachment period, initiate continuous perfusion using the ATF system for cell retention. Set the perfusion rate based on the glucose consumption rate to maintain nutrient levels and remove waste products. This process can support growth to high cell densities [26].

- Cell Harvest (for subsequent 2D exosome production): To harvest cells, stop the perfusion and use the ATF system to perform medium exchange, replacing the culture medium with a washing solution and then a cell detachment enzyme solution. Once cells are detached, separate them from the microcarriers via filtration [26].

- Exosome Production: The harvested and washed cells can then be re-inoculated into a new bioreactor system (like a hollow fiber or fixed-bed bioreactor) specifically for exosome production, or they can be transitioned to 2D flasks with serum-free medium to generate conditioned medium for exosome isolation [27].

Workflow and Signaling Diagrams

Diagram Title: Hollow Fiber Bioreactor Workflow for MSC Exosome Production

Research Reagent Solutions

Table 3: Essential Materials for Bioreactor-Based Exosome Production

| Item | Function | Example Products / Notes |

|---|---|---|

| Bioreactor System | Provides a controlled environment for 3D cell culture and exosome production. | Hollow Fiber (FiberCell Systems, Quantum by Terumo BCT); Stirred-Tank (Single-use benchtop systems) [22] [28] [30]. |

| Microcarriers | Provides a scalable surface for adherent MSC growth in stirred-tank reactors. | Synthemax II-SC, Cytodex; Select based on coating (e.g., collagen, vitronectin) for optimal cell attachment [26]. |

| Cell Retention Device | Enables perfusion culture by retaining cells and microcarriers while removing spent media. | Alternating Tangential Flow (ATF) system, Tangential Flow Depth Filtration (TFDF) [26]. |

| Culture Medium | Supports MSC expansion and viability. | α-MEM, DMEM/F12; often supplemented with FBS or, for clinical translation, Human Platelet Lysate (hPL) [23] [30]. |

| Production Medium | Used during exosome collection to avoid contaminating vesicles from serum. | Serum-free medium (SFM), EV-depleted media [28] [30]. |

| Purification Filters/Columns | For concentrating and purifying exosomes from large volumes of conditioned media. | Tangential Flow Filtration (TFF) systems, Size-Exclusion Chromatography (SEC) columns, Monolithic anion-exchange columns [28] [29]. |

| Characterization Kits | For validating exosome identity, size, and concentration. | Nanoparticle Tracking Analysis (NTA), Transmission Electron Microscopy (TEM) reagents, Antibodies for CD63, CD81, TSG101 [24] [25] [28]. |

Troubleshooting Guides

Media Selection and Formulation

Issue: Suboptimal MSC proliferation and sEV yield. Question: How does the choice of basal media affect MSC growth and subsequent small extracellular vesicle (sEV) production?

Solution: The selection of basal culture medium is a critical foundational parameter. Research indicates that Alpha Minimum Essential Medium (α-MEM) may offer advantages over Dulbecco's Modified Eagle Medium (DMEM) for culturing Bone Marrow-MSCs (BM-MSCs). A 2025 study performed a direct comparison of these media, both supplemented with 10% human platelet lysate (hPL), and found that while results were not statistically significant, BM-MSCs cultured in α-MEM consistently showed higher proliferative capacity and expansion ratios [5]. Furthermore, the average yield of sEV particles per cell was higher in α-MEM (4,318.72 ± 2,110.22) compared to DMEM (3,751.09 ± 2,058.51) [5]. This suggests that α-MEM creates a more favorable environment for MSC expansion and sEV biogenesis.

Table 1: Comparison of MSC Performance in DMEM vs. α-MEM

| Parameter | DMEM | α-MEM | Significance |

|---|---|---|---|

| Cell Population Doubling Time (Passage 3-6) | 1.90 - 2.25 days | 1.85 - 1.99 days | Not Significant [5] |

| Expansion Ratio | Lower | Higher | Not Significant [5] |

| sEV Particle Yield/Cell | 3,751.09 ± 2,058.51 | 4,318.72 ± 2,110.22 | Higher in α-MEM [5] |

| sEV Mean Size | 114.16 ± 14.82 nm | 107.58 ± 24.64 nm | Comparable [5] |

Experimental Protocol: Media Comparison

- Cell Culture: Culture BM-MSCs from a consistent donor source (passage 3-6) in parallel using DMEM and α-MEM, both supplemented with 10% hPL.

- Proliferation Assay: Monitor cell morphology daily. At each passage, calculate the Cell Population Doubling Time (CPDT) and time to reach 90% confluency. Determine the expansion ratio (fold-increase in cell number per passage).

- sEV Isolation and Characterization: At ~80% confluency, switch MSCs to a serum-free medium for 48 hours to collect conditioned medium (CM). Isolate sEVs using a consistent method (e.g., Tangential Flow Filtration or Ultracentrifugation). Characterize sEVs using:

- NTA (Nanoparticle Tracking Analysis): To determine particle concentration and size distribution [5].

- TEM (Transmission Electron Microscopy): To confirm cup-shaped morphology [5].

- Western Blot: To confirm the presence of sEV markers (e.g., CD9, CD63, TSG101) and the absence of negative markers (e.g., Calnexin) [5].

Diagram 1: Experimental workflow for media comparison.

Dissolved Oxygen Concentration

Issue: Reduced MSC fitness and therapeutic potential under standard culture conditions. Question: What is the impact of dissolved oxygen tension on MSC metabolism, proliferation, and secretome?

Solution: Conventional normoxic (21% O₂) culture does not reflect the physiological hypoxic (1-7% O₂) niches of tissues like bone marrow and umbilical cord [31] [32]. Culturing MSCs under hypoxic conditions (e.g., 1.5% to 5% O₂) can significantly enhance their proliferative capacity and reduce cell damage, as evidenced by lower LDH release [31]. This is mediated by the induction of Hypoxia-Inducible Factor 1-alpha (HIF-1α), which upregulates energy metabolism genes (e.g., GLUT-1, LDH, PDK1), leading to increased glucose consumption and lactate production [31]. Hypoxic preconditioning also alters the proteomic profile of the MSC secretome, potentially enhancing its therapeutic properties for applications like neural differentiation [32].

Experimental Protocol: Hypoxic Preconditioning

- Setup: Use a tri-gas incubator capable of precise control over O₂ (1.5%, 2.5%, 5%), CO₂ (5%), and temperature (37°C). For online monitoring, employ a shake flask reader with optical sensors for dissolved O₂ and pH [31].

- Culture: Expand MSCs (e.g., Umbilical Cord-derived) under normoxic (21% O₂) and hypoxic conditions. Maintain cultures for a defined period (e.g., 72 hours [31]).

- Analysis:

- Viability/Proliferation: Count cells using a hemocytometer and trypan blue exclusion. Assess apoptosis (Caspase-3/7 assay) and necrosis (LDH assay) [31].

- Metabolism: Measure glucose and lactate levels in the spent medium. Calculate oxygen consumption rates from dissolved oxygen data [31].

- Molecular Analysis: Confirm HIF-1α protein induction via Western Blot [31]. Analyze changes in secretome profile via proteomics (e.g., mass spectrometry) [32].

Diagram 2: Cellular response to hypoxic preconditioning.

Feeding Strategies and Metabolic Management

Issue: Nutrient depletion and accumulation of metabolic waste products inhibiting MSC growth and sEV production. Question: How frequently should culture media be refreshed to maintain optimal MSC proliferation?

Solution: To consistently provide fresh nutrients and remove metabolic waste like lactate, culture media should be refreshed every 48 to 72 hours [33]. This practice prevents nutrient depletion, maintains optimal pH, and reduces cell stress, which is crucial for robust MSC proliferation and consistent sEV production during scalable manufacturing. For high-density cultures in bioreactors, a perfusion mode of operation can be employed to achieve continuous nutrient supply and waste removal, ensuring a stable microenvironment [32].

Frequently Asked Questions (FAQs)

Q1: Besides basal media, what other media components are critical for GMP-compliant MSC culture? A1: For clinical-grade exosome production, it is essential to use xeno-free and chemically defined components. Fetal Bovine Serum (FBS) should be replaced with supplements like human Platelet Lysate (hPL) [5]. The entire medium should be formulated with animal origin-free (AOF) components to eliminate the risk of zoonotic infections and batch-to-batch variability, ensuring compliance with Good Manufacturing Practice (GMP) standards [34] [35].

Q2: How does the method of sEV isolation impact yield and quality for scaling production? A2: The isolation method significantly affects yield and scalability. Tangential Flow Filtration (TFF) is a more scalable and efficient method compared to the traditional Ultracentrifugation (UC). A 2025 study demonstrated that TFF provided statistically higher particle yields than UC [5]. TFF is more suitable for processing large volumes of conditioned medium, making it the preferred choice for industrial-scale sEV production [5] [27].

Q3: What is the recommended cell seeding density to maximize MSC growth efficiency? A3: The optimal MSC seeding density is approximately 5,000 cells/cm² [33]. This density provides adequate space and resources for efficient proliferation, preventing stress from overcrowding (contact inhibition) or overly sparse seeding. Maintaining this recommended density ensures optimal nutrient availability and metabolic waste management.

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Optimizing MSC Culture and sEV Production

| Reagent / Material | Function / Application | Key Considerations |

|---|---|---|

| α-MEM Basal Medium | Supports MSC expansion and sEV production. | Shows trends of superior performance for BM-MSC proliferation and sEV yield compared to DMEM [5]. |

| Human Platelet Lysate (hPL) | Xeno-free supplement for clinical-grade MSC culture. | Replaces FBS to reduce immunogenicity and comply with GMP standards [5] [35]. |

| Animal Origin-Free (AOF) Medium | A chemically defined, serum-free medium for GMP-compliant production. | Eliminates batch variability and infection risk; essential for manufacturing therapies for human use [34]. |

| TrypLE or Accutase | Gentle enzymatic dissociation agents for cell passaging. | Prevents damage to surface proteins, preserving MSC viability and function during subculturing [33]. |

| Tangential Flow Filtration (TFF) System | Scalable isolation of sEVs from large volumes of conditioned medium. | Provides higher particle yields compared to ultracentrifugation; essential for industrial-scale production [5]. |

| Fixed-Bed Bioreactor | Automated, large-scale expansion of MSCs for high-volume sEV harvest. | Enables high-density cell culture with tight control over process parameters (pH, O₂); yields > 5x10^8 cells/batch [27]. |

The choice between Ultracentrifugation (UC) and Tangential Flow Filtration (TFF) is critical for the yield, quality, and scalability of mesenchymal stem cell (MSC)-derived exosome production. The following table summarizes core performance metrics derived from recent comparative studies.

Table 1: Quantitative Comparison of UC and TFF for MSC-derived Exosome/Small EV Isolation