Strategic Frameworks for Consistent Quality in Autologous Cell Therapy Manufacturing

This article provides a comprehensive guide for researchers, scientists, and drug development professionals on establishing robust strategies to ensure consistent quality in autologous cell therapies.

Strategic Frameworks for Consistent Quality in Autologous Cell Therapy Manufacturing

Abstract

This article provides a comprehensive guide for researchers, scientists, and drug development professionals on establishing robust strategies to ensure consistent quality in autologous cell therapies. It explores the foundational challenges posed by patient-specific starting materials, details advanced methodological solutions like automation and decentralized manufacturing, addresses critical troubleshooting for supply chain and expansion, and outlines rigorous validation and comparability frameworks. By synthesizing current technological innovations and regulatory perspectives, this resource aims to support the scalable production of safe, efficacious, and reliable personalized cell therapies.

Understanding the Unique Quality Challenge: The Variable Nature of Autologous Starting Materials

For researchers developing autologous cell therapies, the inherent variability of patient-derived cellular starting material is a fundamental and pervasive challenge. Unlike traditional pharmaceuticals or allogeneic therapies that use controlled donor material, autologous therapies must contend with the biological reality that every patient's cells are unique. This variability, stemming from factors like the patient's disease state, prior treatments, and individual biology, directly impacts the manufacturing consistency, product quality, and ultimately, the reproducibility of experimental and clinical outcomes [1] [2].

Success in this field depends on moving from simply observing variability to actively managing it. This guide provides targeted troubleshooting advice and strategies to help you identify, quantify, and control the variability in your starting materials, thereby building a more robust foundation for your autologous therapy research.

Quantifying the Variability: Key Data for the Researcher

A critical first step is understanding the scope and scale of inherent variability. The following tables summarize key quantitative findings that illustrate this challenge, providing a benchmark for your own experimental data.

Table 1: Variability in Leukapheresis Collections from Healthy Donors

This data, derived from over 2,000 leukapheresis procedures, demonstrates the inherent variability even in starting material from healthy donors, highlighting a fundamental challenge for process development [2].

| Cell Population | Observed Range | Implication for Research & Development |

|---|---|---|

| Total White Blood Cell Yield | < 5 billion to > 30 billion cells | Impacts scale of manufacturing; may necessitate process scaling or result in insufficient yield for target dose. |

| CD3+ T Cell Percentage | High donor-to-donor variation | Affects efficiency of T-cell focused processes (e.g., CAR-T); can lead to inconsistency in initial cell input. |

| NK Cell Percentage | High donor-to-donor variation | Influences the final product's cellular composition, potentially affecting product phenotype and function. |

| B Cell Percentage | High donor-to-donor variation | Can be a critical contaminant in T-cell products; variability requires robust purification methods. |

Table 2: Impact of Variability on Critical Quality Attributes (CQAs)

Variability in the starting material can propagate through the entire manufacturing process, affecting key quality attributes of the final drug product [3] [4].

| Critical Quality Attribute (CQA) | Impact of Starting Material Variability | Common Assessment Methods |

|---|---|---|

| Cell Identity/Phenotype | Donor-specific immune cell subset ratios can shift during expansion, affecting final product composition [4]. | Flow cytometry, transcriptional fingerprinting (RNA-seq) [4]. |

| Potency/Functionality | Variations in initial T cell fitness can lead to differences in expansion potential and final cytotoxic or suppressive activity [3]. | Functional assays (e.g., tumor cell killing, suppression assays), cytokine secretion profiles [4]. |

| Viability and Expansion Capacity | Health of the patient's cells at collection can dictate maximum achievable expansion and final cell viability [3] [5]. | Cell counting (viability dyes), metabolic activity assays, cumulative population doublings. |

Troubleshooting Guides & FAQs

This section addresses specific, high-frequency problems researchers encounter due to starting material variability.

FAQ 1: How can we account for extreme donor-to-donor variability in our experimental results?

The Challenge: Your in vitro potency or expansion data shows high standard deviations, making it difficult to draw statistically significant conclusions about process changes or product efficacy.

Solution Strategy:

- Strategic Donor Sourcing: Whenever possible, utilize repeatable, recallable donor sources for your non-clinical studies. This allows you to select donors with specific biological characteristics (e.g., high CD3+ percentage) that best fit your process, improving consistency [2].

- Increase Sample Size: Power your experiments with a sufficient number of biological replicates (n) from diverse donors to adequately capture and account for expected population variability.

- Implement Robust Controls: Include a standardized control (e.g., cells from a characterized donor or cell line) in every experiment to benchmark performance and separate process-related effects from donor-related effects.

- Data Stratification: Post-experiment, stratify your data based on key starting material attributes (e.g., pre-apheresis lymphocyte count, donor age). This can reveal correlations and help define critical material specifications [2].

FAQ 2: Our cell expansion yields are inconsistent. What are the key factors to control?

The Challenge: The fold-expansion of T cells or other therapeutic cells varies significantly between batches, leading to unpredictable final cell counts.

Solution Strategy:

- Standardize Cell Activation: Ensure consistency in activation methods. The type (soluble vs. bead-bound antibodies), concentration, and timing of activation stimuli (e.g., anti-CD3/CD28) are critical. Use GMP-grade reagents to minimize batch-to-batch reagent variability [3] [6].

- Optimize Culture Media: Systemically test and qualify basal media and serum/serum-free supplements. Monitor metabolite consumption (e.g., glucose, glutamine) to understand metabolic phenotypes and optimize feeding schedules [3].

- Control Cell Density: Maintain optimal cell seeding densities throughout the culture process. High or low densities can lead to premature senescence or suboptimal growth [3].

- Monitor Starting Material Health: Assess the viability and functional status of cells immediately after collection. A poor starting point often predicts a poor expansion outcome [5].

FAQ 3: What advanced methods can ensure the identity and stability of cell products like Tregs?

The Challenge: Traditional markers like FOXP3 for Tregs may be insufficient to guarantee a stable and functional identity after extensive ex vivo manipulation and expansion [4].

Solution Strategy:

- Go Beyond Surface Phenotyping: Implement transcriptional fingerprinting via bulk or single-cell RNA-seq. This method can define a precise, multi-gene "identity fingerprint" that distinguishes your target cell type from others (e.g., Tregs from effector T cells) with high sensitivity and specificity [4].

- Develop a Stability Fingerprint: Create a second transcriptional fingerprint that characterizes the expanded state of the cells, helping to ensure the manufacturing process does not drive them toward an undesired differentiation state [4].

- Correlate with Function: Use advanced bioinformatics to correlate these molecular fingerprints with the results of your in vitro potency assays (e.g., suppression assays). This creates a more comprehensive and predictive quality control profile than any single metric alone [4].

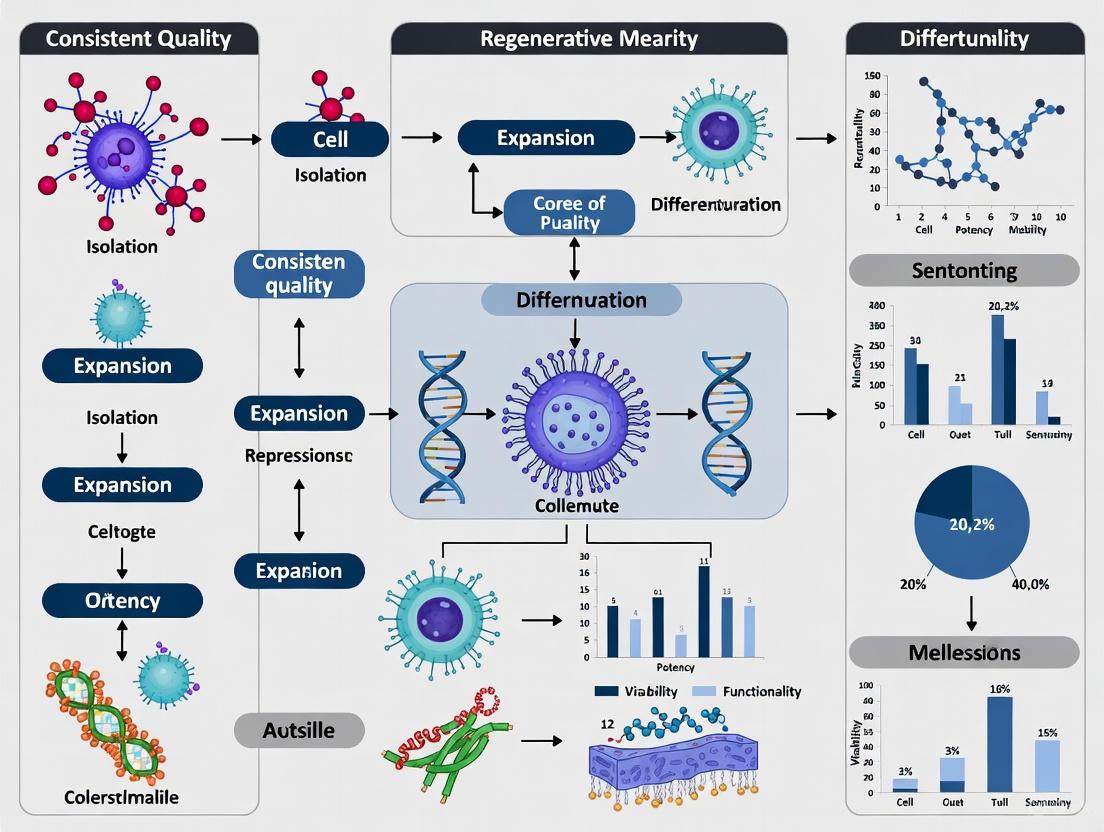

Diagram 1: A workflow for managing variability from starting material to final product, showing key control points and potential failure modes.

The Scientist's Toolkit: Essential Research Reagents & Materials

A robust research process requires high-quality, well-defined reagents. The following table details essential materials for developing autologous cell therapies, with a focus on mitigating variability.

Table 3: Key Research Reagent Solutions for Cell Therapy R&D

| Reagent/Material | Function & Application | Considerations for Reducing Variability |

|---|---|---|

| Cell Isolation Kits (e.g., MACS, FACS) | Isolate specific cell populations (e.g., CD4+ T cells, Tregs) from heterogeneous apheresis product [3]. | Use closed, automated systems to reduce contamination and operator-dependent variability. Validate recovery and purity for each cell type [6]. |

| Activation Reagents (e.g., anti-CD3/CD28 beads) | Activate T cells to initiate proliferation and enable genetic modification [3]. | Use GMP-grade, detachable beads for consistent stimulation strength and easy removal, minimizing carryover and batch effects [6]. |

| Cell Culture Media & Supplements | Provide nutrients and signaling molecules for cell survival, expansion, and differentiation [3]. | Use serum-free, xeno-free, chemically defined media to eliminate lot-to-lot variability introduced by animal sera. Pre-qualify cytokine supplements (e.g., IL-2) [3]. |

| Cryopreservation Media | Preserve cell viability and function during long-term storage and transport [3]. | Use controlled-rate freezing and standardized cryoprotectant concentrations (e.g., DMSO) to ensure consistent post-thaw recovery and functionality [3]. |

| Transcriptional Profiling Kits (RNA-seq) | Assess cell identity, purity, and stability via gene expression analysis [4]. | Implement standardized RNA extraction and library prep protocols. Use predefined gene signatures ("fingerprints") for objective quality scoring [4]. |

Experimental Protocol: Transcriptional Fingerprinting for Treg Identity

This protocol provides a detailed methodology for implementing transcriptional fingerprinting, an advanced strategy to ensure the quality of cell products like Tregs, as discussed in the troubleshooting section [4].

Objective: To molecularly characterize expanded Treg products and score them for stable identity and expansion-associated changes using bulk RNA-seq.

Materials:

- Purified Tregs (e.g., CD4+CD25hiCD127lo) and Teff cells (CD4+CD25loCD127hi) from PBMCs.

- FACS sorter.

- Cell culture reagents: CTS OpTmizer T Cell Expansion Media, anti-CD3/anti-CD28 Dynabeads.

- RNA stabilization solution and RNA extraction kit.

- Next-generation sequencing platform (e.g., Illumina).

- Computational tools for analysis (e.g., R, Python, with packages for ssGSEA or GSVA).

Methodology:

- Cell Isolation and Culture:

- Isolate PBMCs from leukapheresis product via Ficoll density gradient centrifugation.

- Sort Treg and Teff populations by FACS using defined surface markers.

- Culture sorted cells, activating them with anti-CD3/anti-CD28 Dynabeads and expanding for 14 days in optimized media.

RNA Sequencing:

- Sample Collection: Pellet at least 1x10^6 cells from both pre-expansion (D0) and post-expansion (D14) time points. Stabilize RNA immediately.

- RNA Extraction & QC: Extract total RNA. Ensure RNA Integrity Number (RIN) is ≥8.0 before proceeding.

- Library Prep & Sequencing: Construct Illumina-compatible mRNA libraries. Sequence to a minimum depth of 25 million paired-end 150bp reads per sample.

Computational Analysis & Fingerprint Scoring:

- Data Processing: Align raw sequencing reads (FASTQ) to a reference genome and generate a gene expression count matrix.

- Fingerprint Application: Apply a pre-defined, activation-independent Treg identity gene set to your data using a non-parametric algorithm (e.g., ssGSEA).

- Scoring: Generate two key scores for each sample:

- Identity Score: Measures how closely the sample's transcriptome aligns with a canonical Treg signature versus a Teff signature.

- Expansion Score: Characterizes the transcriptomic impact of the ex vivo expansion process.

- Validation: Correlate fingerprint scores with functional assay outcomes (e.g., in vitro suppression assays) to validate the biological relevance of the scores.

Diagram 2: Experimental workflow for transcriptional fingerprinting of Treg cell products.

Defining Critical Quality Attributes (CQAs) for Patient-Specific Products

FAQ: Understanding CQAs and Their Importance

What are Critical Quality Attributes (CQAs) in the context of autologous cell therapies?

Critical Quality Attributes (CQAs) are physical, chemical, biological, or microbiological properties or characteristics that must be within an appropriate limit, range, or distribution to ensure the desired product quality [7] [8]. For a living drug product like autologous cell therapy, CQAs are central to confirming the product's identity, purity, potency, safety, and viability [9]. They are defined early in the product development stage based on the desired Quality Target Product Profile (QTPP) [8].

Why is defining CQAs particularly challenging for patient-specific (autologous) products?

Unlike allogeneic (donor-derived) or conventional biopharmaceutical products, autologous therapies are manufactured starting with a patient's own cells. This presents unique challenges [7]:

- Variable Starting Material: You are "beholden to the quality of the patient cells." The patient's disease stage, previous therapies, and genetic background create inherent variability in the apheresis starting material, which is difficult to control [7] [10].

- Lack of "Fail-Safes": Cell therapies cannot undergo traditional pathogen removal steps like filtration or low pH inactivation, as these would kill the living cells. This makes in-process control and a strong understanding of CQAs even more critical for patient safety [7].

At what stages of the manufacturing process should CQAs be assessed?

Quality testing should be performed at multiple points to ensure control throughout the production journey [10]:

- Donor/Patient Testing: Medical history and infectious disease screening (though this is less critical for autologous products than allogeneic) [7] [10].

- Starting Material (Apheresis): Testing for cell concentration, viability, purity (e.g., via flow cytometry), identity, and sterility [10].

- In-Process Testing: Monitoring critical steps like cell expansion rates, transduction efficiency, and sterility during manufacturing [10] [8].

- Final Product (Lot Release) Testing: A comprehensive assessment of the final drug product against all specified CQAs, including potency, purity, identity, safety (sterility, endotoxin), and viability, before release for infusion [10] [9].

Troubleshooting Guide: Common CQA Challenges and Solutions

This guide addresses specific, frequently encountered issues when defining and measuring CQAs for autologous cell therapies.

Problem 1: High Variability in Starting Material

- Issue: The quality and composition of patient-derived apheresis material vary significantly from lot to lot, leading to inconsistent process performance and final product CQAs.

- Background: For autologous therapies, the ability to control the quality of the source material is limited. Some variability is inevitable due to the patient's disease and prior treatment history [7]. Consistency testing measures this lot-to-lot variability, which may be due to differences in the collection process or the patients themselves [10].

- Solution:

- Define Apheresis Parameters: Establish strict, specified limits for the collection procedure, including collection volume and the type of anticoagulant used [7].

- Implement Robust In-Process Controls (IPCs): Define IPC acceptance criteria for the starting material, such as minimum cell count and viability, before initiating the manufacturing process [8].

- Process Robustness: Design a manufacturing process that can tolerate a degree of input variability. Using high-quality raw materials and closed, automated processing equipment can help alleviate process variability [6].

Problem 2: Inconsistent Potency Assay Results

- Issue: The potency assay, which measures the biological activity of the product, yields inconsistent or irreproducible results, delaying product release.

- Background: Potency is a quantitative measure of the biological activity linked to the product's intended clinical effect [10]. It is one of the most important yet challenging CQAs [9]. For complex therapies like Treg cells, a single assay may be insufficient, as the product has a "poly-pharmaceutical nature" with multiple functions [11].

- Solution:

- Begin Development Early: Start developing and optimizing the potency assay well in advance, as it can take over 12 months to finalize [9].

- Use Multiple Complementary Assays: Instead of a single test, employ multiple assays that measure different product attributes associated with potency (e.g., cytolytic activity, suppressive cytokine production) [9] [11].

- Implement Controls: Always run appropriate positive and negative controls to qualify the assay performance and your sample [12].

Problem 3: Failure to Meet Viability or Purity CQAs at Final Product Release

- Issue: The final cell product has low viability or an unacceptable level of impurity cells (e.g., tumor cells in an apheresis product).

- Background: Viability and purity are critical for both safety and efficacy. Low viability may affect the dosage, while impurities can pose a patient safety risk [8]. Processes with many open, manual manipulations and shear stress from certain equipment can adversely affect cell health [7] [6].

- Solution:

- Optimize Manufacturing Equipment: Utilize low-shear, closed, and automated systems for cell processing to support high viability and minimize contamination risk [6].

- Define Purification Steps: Implement and validate robust cell isolation or enrichment techniques (e.g., magnetic bead-based selection or flow cytometry-based sorting) to ensure a pure population of the desired cell type [11].

- Establish Clear IPC Criteria: Monitor viability and purity at key in-process stages (e.g., after isolation, after expansion) to catch issues early and allow for process adjustments [8].

Problem 4: Lack of Process Understanding for Tech Transfer

- Issue: When transferring a process from research to a GMP facility or between sites, the product's CQAs change, indicating a lack of process understanding.

- Background: Translating from research-grade to clinical-grade manufacturing is challenging. A common mistake is moving too quickly without building strong GMP principles early on, which makes later tech transfer difficult and expensive [7] [8].

- Solution:

- Adopt a Quality-by-Design (QbD) Framework: Use a systematic approach early in development to link Critical Process Parameters (CPPs) to your CQAs. This builds process understanding and predictability [8].

- Utilize a GMP Simulation Unit: If available, work with a GMP simulation facility to bridge the gap between research and GMP production, allowing for process qualification and validation before full-scale GMP runs [8].

- Perform Comparability Testing: When scaling up or modifying a process, perform comparability testing to demonstrate that cells produced with the new method are equivalent to those produced with the original method in terms of critical quality attributes [10].

CQA and Process Parameter Tables for Autologous Therapy

The following tables provide a structured overview of common CQAs and their connections to the manufacturing process, using a CAR-T cell therapy as an example.

Table 1: Final Product Critical Quality Attributes (CQAs) and Testing Methods

| CQA Category | Specific Attribute | Justification & Impact | Common Testing Methods |

|---|---|---|---|

| Safety | Sterility, Mycoplasma, Endotoxin | Directly affects patient safety; required for release [10] [8]. | Microbial culture, PCR [10] [9]. |

| Vector Copy Number (VCN) | Addresses risk from insertional mutagenesis; affects safety [8] [9]. | ddPCR, qPCR [9]. | |

| Potency | Biological Activity (e.g., Cytolytic activity) | Confirms consistency, stability, and quality between lots; measures intended function [10] [8]. | Co-culture assays with target cells, cytokine release assays [8] [9]. |

| Purity & Identity | % Viable Cells | Low viability may affect the dosage given to the patient [8]. | Dye exclusion assays (e.g., Trypan Blue) [10]. |

| % CAR+ T-cells (Identity/Purity) | Ensures the product contains the engineered cells; affects dosage and consistency [8]. | Flow Cytometry [9]. | |

| Impurities (e.g., % Tumor Cells) | May affect patient safety and the dosage given [8]. | Flow Cytometry [8]. | |

| Quantity | Total Viable Cell Count & Dose | Determines the absolute number of cells for infusion [10]. | Automated cell counters, flow cytometry [10]. |

Table 2: Linking CQAs to Critical Process Parameters (CPPs) and In-Process Controls (IPCs)

| Critical Process Parameter (CPP) | Related CQA(s) | Justification | Recommended In-Process Control (IPC) [8] |

|---|---|---|---|

| Transduction Process | Identity (% CAR+ cells), Potency, Safety (VCN) | The efficiency of gene introduction is fundamental to product identity and function. | Transduction efficiency (e.g., Day 5), Vector Copy Number (e.g., Day 12) |

| Cell Culture Process | Viability, Potency, Purity | Culture conditions (media, duration, parameters) directly impact cell health, expansion, and function. | Cell count & viability (e.g., Day 5, Day 12), Cell morphology |

| Media Exchange / Formulation | Viability, Purity (ancillary materials) | The process of washing and formulating the final product impacts viability and removes impurities. | Viability (Final Product), Assessment of residual beads/reagents |

The Scientist's Toolkit: Essential Reagents & Materials

The following reagents and instruments are critical for developing and controlling the manufacturing process for autologous cell therapies.

Table 3: Key Research Reagent Solutions for CQA Assessment

| Reagent / Material | Function in CQA Assessment | Example & Notes |

|---|---|---|

| Cell Separation Beads | Isolation of specific cell populations (e.g., T-cells) from apheresis material to ensure purity [11]. | Magnetic beads conjugated with antibodies (e.g., anti-CD3/CD28) for activation and expansion [6]. |

| Cell Culture Media & Supplements | Supports cell expansion and maintenance of cell viability and potency during manufacturing. | Serum-free media formulations; use of supplements like rapamycin to maintain Treg phenotype during expansion [11]. |

| Viral Vectors | Genetic engineering of cells to introduce a CAR or other modifying genes, critical for product identity and potency. | Lentiviral or retroviral vectors; monitoring of transduction efficiency is a key IPC [8]. |

| Flow Cytometry Antibodies | Identity and purity testing by detecting surface and intracellular markers (e.g., CD3, CAR expression). | Essential for quantifying % CAR+ cells and characterizing cell phenotype at multiple stages [9]. |

| qPCR/ddPCR Reagents | Safety and identity testing, specifically for measuring Vector Copy Number (VCN) and sterility. | Used for quantifying genomic titer in AAV therapies or VCN in cell therapies [9]. |

Experimental Protocol: Developing a Multi-Parameter Potency Assay

Objective: To establish a robust, quantitative potency assay for an autologous CAR-T cell product that can be used for in-process and lot-release testing.

Background: A potency assay must provide a quantitative measure of the biological activity most relevant to the product's mechanism of action. Given the complexity of cell therapies, a multi-parameter approach is often necessary [9] [11].

Methodology:

- Define Mechanism of Action (MoA): Based on preclinical data, identify the key biological functions of your product. For CAR-T cells, this is typically target cell killing and cytokine secretion [9].

- Develop Individual Assay Modules:

- Cytolytic Activity Assay:

- Co-culture CAR-T cells with fluorescently labeled target cells (positive for the target antigen) at various effector-to-target (E:T) ratios.

- After a defined incubation period (e.g., 4-24 hours), measure target cell lysis using a real-time cell analyzer or by measuring fluorescence release.

- Include controls: CAR-T cells with non-target cells (negative control) and a reference CAR-T cell lot (positive control).

- Cytokine Secretion Assay:

- Following the co-culture, collect the supernatant.

- Use a multiplex ELISA or LEGENDplex assay to quantify the concentration of key cytokines (e.g., IFN-γ, IL-2, Granzyme B).

- Cytolytic Activity Assay:

- Assay Validation (Fit-for-Purpose & Beyond):

- Precision: Determine intra-assay and inter-assay variability.

- Linearity & Range: Demonstrate the assay is linear and accurate across a range of cell doses and potencies.

- Specificity: Show that the response is specific to the intended target antigen.

- Establish a Potency Index: Combine the results from the individual assay modules into a single Potency Index score. For example:

- Potency Index = (Normalized Cytolytic Activity × 0.6) + (Normalized IFN-γ Secretion × 0.4)

- The weighting of each parameter should reflect its relative importance to the MoA.

CQA Control Strategy Workflow

The following diagram illustrates the logical workflow for developing and implementing a control strategy based on CQAs, from early research through GMP manufacturing.

Regulatory Frameworks and Evolving Standards for Autologous Therapy Consistency

FAQs on Regulatory Frameworks & Quality Standards

What are the core regulatory and quality challenges in autologous cell therapy manufacturing?

The primary challenges stem from the personalized nature of the product. Each batch is for a single patient, which introduces significant variability and complicates standardization [13] [14]. Key challenges include:

- Process Complexity: The multi-step process (cell collection, genetic modification, expansion, infusion) requires precise control at each stage to ensure consistent product quality [13].

- Scalability: Expanding from single-center trials to commercial-scale production while maintaining quality is difficult [13].

- Product Consistency: Achieving lot-to-lot consistency is challenging due to variability in starting material (from different patients or the same patient at different times) and the complexity of the manufacturing process [10] [15].

- High Costs: The individualized nature of treatment, specialized facilities, and extensive quality control lead to high manufacturing costs [13] [16].

- Regulatory Compliance: Meeting stringent Good Manufacturing Practice (GMP) requirements across different regions adds a layer of complexity to the manufacturing process [13].

How do regulatory frameworks like GMP address the risk of contamination?

GMP guidelines mandate stringent controls to prevent contamination, which is critical for patient safety. This involves maintaining cleanroom facilities, using high-quality raw materials, and implementing robust quality control measures [13]. The use of closed, automated systems is central to this strategy, as it minimizes human intervention and open-process steps, thereby reducing contamination risks [13]. Furthermore, environmental controls are critical, and manufacturers must perform extensive monitoring of the production environment [14].

What is the role of potency assays in ensuring therapy consistency?

A potency assay is a quantitative measure of the biological activity of a product and is a critical release criterion for the final product [10]. It is intended to ensure that each batch of the therapy is capable of producing its intended clinical effect. The development of these assays is progressive and should be validated prior to Phase III clinical trials [10]. Potency testing is a key tool for regulators and manufacturers to ensure product consistency, stability, and comparability, especially when manufacturing processes are scaled up or modified [10] [15].

What are "comparability" and "consistency" testing, and why are they important?

These are related but distinct concepts in quality assurance:

- Consistency Testing: Measures the lot-to-lot variability of products manufactured using the same protocol. Variability can arise from differences in the starting material (donor genetics, patient health status) or from the manufacturing process itself (reagents, equipment, operator technique) [10].

- Comparability Testing: This is performed to demonstrate that products manufactured using different methods (e.g., during a scale-up of production) are comparable in terms of quality, safety, and efficacy. This is crucial for ensuring that process changes do not adversely affect the final product [10].

How is the regulatory landscape evolving to support autologous therapies?

Regulatory agencies have established specialized pathways to accelerate the development of these innovative treatments. In the US, the 21st Century Cures Act has helped accelerate development timelines [16]. The FDA's Regenerative Medicine Advanced Therapy (RMAT) designation provides expedited development and review for qualifying therapies [16]. Similarly, the European Medicines Agency (EMA) has streamlined processes through its Advanced Therapy Medicinal Products (ATMP) regulation and PRIME scheme [16].

Troubleshooting Common Experimental & Manufacturing Challenges

Challenge: High variability in cell quality and potency between batches.

- Potential Cause: Inconsistency in the starting biological material due to donor-related factors (genetics, health status, age) or variability in the collection process [10] [15].

- Solutions:

- Implement Rigorous Donor Screening: Establish strict criteria for the health status of autologous donors, though this is more challenging for patient-derived cells [10].

- Characterize Starting Material Thoroughly: Perform in-process testing on the starting material, including cell concentration, viability, purity (e.g., via flow cytometry), and identity [10].

- Use Process Controls: Establish and monitor critical control points during manufacturing. Charting the results of these controls over time helps define normal performance specifications and identify outliers [15].

Challenge: Inconsistent results from critical quality assays (e.g., cell counting, potency).

- Potential Cause: A lack of measurement assurance, where unaccounted-for variables in the assay protocol itself lead to unreliable data [15].

- Solutions:

- Apply Measurement Assurance Strategies:

- Create a Measurement Process Flow Diagram: Break down the assay into its discrete steps to identify where variability can be introduced [15].

- Use Ishikawa (Cause-and-Effect) Diagrams: Graphically identify all potential sources of variability (equipment, reagents, personnel, methods) [15].

- Employ Design of Experiments (DOE): Systematically vary assay parameters to identify which ones are most sensitive and require tightest control [15].

- Utilize Orthogonal Measurements: Using two or more different methods to measure the same attribute builds confidence if the results agree [15].

- Apply Measurement Assurance Strategies:

Challenge: Failure to meet sterility or environmental control specifications.

- Potential Cause: Breaches in aseptic technique or inadequate monitoring of the manufacturing environment.

- Solutions:

- Adopt Closed Automated Systems: Platforms like the Gibco CTS Rotea or Dynaclect systems are designed as closed systems to minimize contamination risk [13].

- Implement Rapid QC Testing: Migrate to faster, fit-for-purpose sterility and mycoplasma tests to reduce the time products are in quarantine and get results faster, which is critical for products with short shelf-lives [14].

- Enhance Environmental Monitoring: Use automated, integrated solutions to manage and data from environmental controls, which is especially important when scaling from hundreds to thousands of patient batches [14].

Challenge: Lengthy manufacturing lead times for autologous CAR-T products.

- Potential Cause: The multi-week process of cell manufacturing, coupled with time-consuming quality control testing, delays treatment for critically ill patients [14].

- Solutions:

- Process Integration and Decentralization: Streamline production and reduce transportation times by integrating processes and considering decentralized manufacturing facilities [14].

- Automate Key Unit Operations: Automation of steps like cell isolation, activation, and gene editing can enhance efficiency and reduce hands-on time [13].

- Adopt Rapid QC Methods: As mentioned above, implementing faster quality control solutions is a key strategy for reducing the overall vein-to-vein time [14].

Autologous Cell Therapy Manufacturing & Quality Data

| Metric | Value / Trend | Significance for Therapy Consistency |

|---|---|---|

| Global Market Value (2024) | USD 6.8 billion [16] | Indicates substantial investment and ongoing R&D in the field. |

| Projected Market Value (2034) | USD 18.4 billion [16] | Reflects anticipated growth and adoption, increasing need for standardized quality. |

| Compound Annual Growth Rate (CAGR) | 10.4% [16] | Highlights the rapid evolution of the field and its technologies. |

| Primary Market Driver | Rising prevalence of cancer and chronic diseases [16] | Underscores the medical need and the necessity for reliable, consistent therapies. |

| Key Technological Driver | Advancements in cell processing & automation [13] [16] | Directly addresses consistency challenges by reducing manual errors and variability. |

Table 2: Key Quality Testing Points in Autologous Therapy Production

| Testing Phase | Key Objectives | Examples of Tests Performed |

|---|---|---|

| Donor Testing | Ensure safety of starting material, protect staff. | Medical history, infectious disease testing (HIV, HBV, HCV) [10]. |

| Starting Material Testing | Confirm sufficient quantity and quality of cells collected. | Volume, cell concentration, viability (dye exclusion), purity (flow cytometry), identity (HLA, ABO), sterility [10]. |

| In-Process Testing | Monitor critical steps during manufacturing. | Cell concentration, purity, and sterility at intermediate stages [10]. |

| Final Product (Lot Release) Testing | Ensure final product meets all specifications for safety, purity, and potency before infusion. | Cell quantity, purity, viability, sterility, mycoplasma, endotoxin, and potency [10] [14]. |

Essential Experimental & Quality Control Protocols

Protocol 1: Automated Cell Processing with the Gibco CTS Rotea System

The Gibco CTS Rotea Counterflow Centrifugation System is a closed, flexible system designed for GMP-compliant cell therapy manufacturing. It helps standardize unit operations, reducing operator-induced variability [13].

Applications: Leukopak processing, PBMC separation, cell wash and concentration, buffer exchange [13]. Key Features:

- Closed System: Minimizes contamination risk.

- Low Output Volume: Ideal for autologous processes with limited cell numbers.

- High Cell Recovery and Viability: Optimized for sensitive primary cells. Methodology: The system uses counterflow centrifugation, where cells are suspended in a fluid flowing opposite to the centrifugal force. This allows for gentle and efficient separation, washing, and concentration of cells based on size, density, and sedimentation rate. The specific protocols (centrifugal speed, flow rates, buffer volumes) are programmed into the user-friendly interface and can be customized for the specific cell type and processing goal.

Protocol 2: Enzymatic Cell Dissociation for Primary Tissue

This is a common method to obtain single-cell suspensions from primary tissue, a critical step for many autologous therapies [17].

Reagents: Collagenase solution in HBSS with calcium and magnesium. Detailed Steps:

- Mince Tissue: With sterile instruments, mince tissue into 3–4 mm pieces [17].

- Wash Tissue: Wash the tissue pieces several times with HBSS containing calcium and magnesium [17].

- Enzymatic Digestion: Submerge tissue in collagenase solution (50–200 U/mL). Supplementing with 3 mM CaCl₂ can increase efficiency [17].

- Incubate: Incubate at 37°C for 4–18 hours on a rocker platform for gentle agitation [17].

- Disperse Cells: Pass the digested mixture through a sterile stainless-steel or nylon mesh (100-200 µM) to separate dispersed cells from tissue fragments [17].

- Wash Cells: Centrifuge the cell suspension and wash several times in HBSS without collagenase [17].

- Resuspend and Count: Resuspend the final cell pellet in culture medium. Determine viable cell density and percent viability using an automated cell counter or manual method [17].

Process Visualization: Workflows and Quality Systems

Autologous Therapy and Quality Control Workflow

Quality Assay Development and Validation Pathway

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Cell Processing and Quality Control

| Item | Function | Application Notes |

|---|---|---|

| Gibco CTS Rotea System | Closed, automated system for cell processing tasks like washing and concentration. | Reduces contamination risk and operator variability; GMP-compliant [13]. |

| Gibco CTS Dynaclect System | Closed, automated system for magnetic cell separation and bead removal. | Used for cell isolation (e.g., CD34+ selection) and de-beading; scalable [13]. |

| Gibco CTS Xenon System | Large-scale, modular electroporation system for non-viral genetic modification. | Enables CAR gene insertion; GMP-compliant and closed system [13]. |

| Enzymatic Dissociation Reagents (TrypLE, Collagenase) | Detach adherent cells from culture surfaces or dissociate primary tissues. | TrypLE is an animal-origin-free alternative to trypsin [17]. |

| Cell Dissociation Buffer | Non-enzymatic, gentle method for detaching lightly adherent cells. | Preserves cell surface proteins that might be damaged by enzymes [17]. |

| Automated Cell Counter | Provides rapid, consistent cell count and viability measurements. | Reduces human error in this fundamental QC step [17] [15]. |

| Flow Cytometry Assays | Measures cell purity, identity, and characterization of specific cell populations. | Critical for testing starting material, in-process samples, and final product [10]. |

| Rapid Sterility/Mycoplasma Kits | Fast microbial detection to meet tight release timelines for short-lived therapies. | Fit-for-purpose solutions are essential to reduce manufacturing lead times [14]. |

Frequently Asked Questions (FAQs)

FAQ 1: How does donor age impact the quality of cells used in autologous therapies? Donor age significantly affects the quantity and functional quality of cells. Mesenchymal stem cells (MSCs) from elderly donors exhibit a "youthful" subpopulation (approximately 8% of the total population) characterized by small cell size and positive expression of Stage-Specific Embryonic Antigen-4 (SSEA-4). However, the overall elderly MSC population shows hallmarks of aging, including [18]:

- Reduced Proliferation: Lower replication capacity and expansion potential.

- Increased Senescence: Higher concentrations of intracellular reactive oxygen species (ROS) and β-galactosidase expression.

- Impaired Energetics: Lower amounts of adenosine triphosphate (ATP). These aging effects can be mitigated by isolating the youthful subpopulation and expanding it on a supportive "young microenvironment," such as a bone marrow-derived extracellular matrix (BM-ECM) [18].

FAQ 2: Why do my autologous cell therapy validation results differ when using healthy donor cells versus patient-derived cells? Cells from patients with diseases, particularly those who have undergone prior treatments, are fundamentally different from those of healthy donors. Using only healthy donor cells for Verification and Validation (V&V) testing fails to capture the real-world biological variations present in patient-derived starting materials [19]. Key differences include [19]:

- Prior Treatments: Patients eligible for autologous therapies (like CAR-T) have often undergone multiple lines of chemotherapy or radiotherapy. These treatments can cause reduced cell production, diminished cytokine production, and altered immune cell subset populations.

- T Cell Function: Chemotherapy-exposed T cells can show diminished proliferation levels and lower viral transduction efficiency when using conventional activation methods.

- Disease Pathology: The disease state itself alters cellular biology and the microenvironment, which is not modeled by healthy cells.

FAQ 3: What specific donor factors contribute to variability in adipose-derived stem cell (ASC) therapies? The clinical efficacy of autologous fat grafting is highly variable, with retention rates ranging from 10% to 80%. This variability is strongly influenced by donor-related factors [20]:

| Donor Factor | Impact on Adipose-derived Stem Cells (ASCs) |

|---|---|

| Age | Younger donors typically have higher ASC proliferation rates and greater regenerative potential. |

| Sex | Hormonal differences between sexes can influence ASC functionality. |

| Health Status | Conditions like obesity or diabetes can impair ASC functionality. Systemic inflammation also alters the adipose tissue microenvironment. |

| Anatomical Harvest Site | Different body regions yield fat with variability in cellular composition, vascularity, and stem cell content. |

FAQ 4: Are there regulatory considerations for cell therapies related to donor variability? Yes. In the US, the FDA regulates Human Cell, Tissue, and Cellular and Tissue-Based Products (HCT/Ps) through two primary pathways based on risk. Section 361 products must meet strict criteria, including minimal manipulation and homologous use, and do not require premarket approval. Section 351 products, which often involve more than minimal manipulation (e.g., expansion, genetic modification), require an IND, clinical trials to demonstrate safety and efficacy, and must adhere to current Good Manufacturing Practices (cGMP). Managing donor variability is critical for Section 351 products to ensure product consistency, which is a key part of the regulatory review [21].

Troubleshooting Guides

Issue 1: Low Proliferation and Senescence in Cells from Elderly Donors

Problem: Cells isolated from an elderly donor show slow growth, enlarged morphology, and high senescence markers, making expansion to therapeutic doses challenging.

Solution: Implement a strategy to isolate and expand the retained youthful subpopulation.

Step-by-Step Protocol:

- Cell Isolation and Characterization: Isolate MSCs from the donor's bone marrow and characterize using standard surface markers (CD73, CD90, CD105) [18].

- Identify Youthful Subpopulation: Use Fluorescence-Activated Cell Sorting (FACS) to isolate cells based on two key parameters [18]:

- Small cell size

- Positive expression of SSEA-4

- Create a Youthful Microenvironment: Culture the isolated SSEA-4+ subpopulation on a bone marrow-derived extracellular matrix (BM-ECM) produced by young donor stromal cells. This ECM provides critical biochemical and physical cues for rejuvenation [18].

- Expand Cells: Culture the cells on the BM-ECM in standard growth medium, supplementing with 50 μM ascorbic acid during the last 8 days of culture to support ECM production and cell health [18].

Visual Guide to Isolating Youthful Cells from Elderly Donors The following workflow diagram illustrates the protocol for rescuing high-quality MSCs from an elderly donor population.

Issue 2: Inconsistent Performance of Patient-Derived Cells in Validation Assays

Problem: Assays used for process validation (e.g., transduction efficiency, proliferation) yield inconsistent and suboptimal results when using cells from diseased donors, despite working well with healthy donor cells.

Solution: Incorporate disease-state primary cells into your V&V testing strategy to better represent the target patient population.

Step-by-Step Protocol:

- Source Disease-State Material: Procure disease-state leukopaks or immune cell subsets from a qualified supplier that provides comprehensive clinical data (e.g., patient diagnosis, disease progression, prior treatments) [19].

- Benchmark Against Healthy Donors: Perform key assays in parallel using cells from healthy donors and disease-state donors. Essential assays include [19]:

- T Cell Proliferation Assay: Activate T cells with CD3/CD28 beads and measure proliferation over time. Expect reduced proliferation in cells from chemotherapy-treated donors [19].

- Transduction Efficiency Assay: Transduce T cells with a viral vector (e.g., for CAR-T) and measure the percentage of successfully modified cells. Chemotherapy exposure can lower transduction rates [19].

- Cytokine Production Profiling: Quantify cytokine output after activation, as this can be diminished in disease-state cells [19].

- Optimize Processes: Use the data from disease-state cells to refine manufacturing processes, media formulations, and activation methods to be more robust for the intended patient population [19].

Comparative Data: Impact of Donor Status on Key T Cell Parameters This table summarizes expected outcomes when comparing cells from healthy donors and patients pre-treated for conditions like oncology or autoimmune disorders.

| Experimental Parameter | Healthy Donor Cells | Disease-State / Pre-treated Donor Cells |

|---|---|---|

| T Cell Proliferation (post CD3/CD28 activation) | Robust proliferation | Diminished levels of proliferation [19] |

| Viral Transduction Efficiency | Standard efficiency | Can be low/reduced [19] |

| Cytokine Production | Normal profile | Diminished production [19] |

| Cell Subset Populations | Standard distribution | Fluctuations and alterations [19] |

Issue 3: High Functional Variability in Adipose-Derived Stem Cells (ASCs)

Problem: Autologous fat grafts or ASC preparations show unpredictable clinical outcomes due to underlying donor biology.

Solution: Pre-screen donors and tailor processing protocols based on donor profile.

Step-by-Step Protocol:

- Donor Profiling: Document key donor factors before the procedure: age, sex, BMI, metabolic health status (e.g., presence of diabetes), and planned anatomical harvest site [20].

- Assess ASC Quality (Optional but Recommended): If feasible, perform a small-scale test culture and quality assessment of the isolated ASCs. Key metrics include [20]:

- Proliferation Rate: Use a colony-forming unit (CFU) assay.

- Viability Staining: Use trypan blue or similar.

- Flow Cytometry: Confirm expression of typical MSC markers (CD90, CD73, CD105, CD44) and lack of hematopoietic markers (CD45, CD14) [20].

- Mitigate Variability: Based on the profile, consider strategies to enhance the graft:

- For older donors or those with compromised health, consider enriching for the stromal vascular fraction (SVF) to increase stem cell concentration [20].

- Use additives like Platelet-Rich Plasma (PRP) or specific growth factors to the graft to boost ASC survival and function [20].

- Standardize the anatomical harvest site whenever possible to reduce one source of variability.

The Scientist's Toolkit: Key Research Reagents & Materials

| Item | Function / Application |

|---|---|

| Bone Marrow-derived Extracellular Matrix (BM-ECM) | A decellularized, native 3D culture system that mimics the stem cell niche. Used to rejuvenate and expand elderly MSCs while retaining stem cell properties [18]. |

| Fluorescence-Activated Cell Sorter (FACS) | An essential tool for isolating specific cell subpopulations based on markers like SSEA-4 and physical characteristics like cell size to obtain "youthful" cells from a heterogeneous elderly population [18]. |

| Disease-State Leukopaks | Peripheral blood mononuclear cells (PBMCs) collected from patients clinically diagnosed with a specific disease. Critical for representative verification and validation (V&V) testing of autologous therapies [19]. |

| Stage-Specific Embryonic Antigen-4 (SSEA-4) Antibody | A cell surface marker used to identify a potent, "youthful" subpopulation of mesenchymal stem cells within a larger, aged population for selective isolation [18]. |

| Colony-Forming Unit (CFU) Assay Kit | A functional assay to quantify the proliferation potential and clonogenicity of stem cells, such as Adipose-derived Stem Cells (ASCs), which is a key indicator of cell quality [20]. |

| Reactive Oxygen Species (ROS) Detection Kit | A fluorescent assay to measure intracellular oxidative stress levels, which are typically elevated in senescent cells from elderly donors or those with certain disease states [18]. |

Implementing Technological and Systemic Solutions for Quality Control

Leveraging Automation and Closed-System Bioreactors to Minimize Process Variability

Troubleshooting Guides

Guide 1: Addressing Contamination in Bioreactor Systems

Q: My bioreactor culture is showing signs of contamination, such as unexpected turbidity or media acidification. What are the most likely sources and immediate corrective actions?

Contamination can lead to significant losses in time and resources. Early detection and a systematic investigation are key to resolving the issue.

| Observation/Symptom | Potential Source | Corrective Action |

|---|---|---|

| Unexpected turbidity, color change (e.g., phenol red to yellow), or unusual smell [22] | Contaminated inoculum or poor inoculation technique [22] | Check the sterility of the seed train by re-plating on a rich growth medium. Review and secure inoculation procedures to avoid "aseptic pour" into open ports [22]. |

| Growth of spore-forming organisms reappearing after autoclaving [22] | Ineffective sterilization cycle or compromised vessel assembly [22] | Verify autoclave temperature with test phials. Completely disassemble the vessel and tubing. Autoclave with pauses between cycles to allow spores to germinate, then re-sterilize [22]. |

| Contamination detected post-inoculation without clear source | Failed seals, O-rings, or wet exit gas filters [22] | Inspect and replace all vessel and sensor O-rings if they are flattened, torn, or feathered (recommended every 10-20 cycles). Check reagent bottle seals and feed lines. Ensure the exit gas cooler is efficient to prevent filter wetting [22]. |

Experimental Protocol: Sterility Hold Test A critical method to confirm the success of your decontamination efforts and the sterility of your bioreactor system before use.

- Preparation: After performing the corrective actions and re-sterilizing the bioreactor, fill it with cell culture medium as you would for a normal experiment.

- Incubation: Instead of inoculating with cells, maintain the bioreactor at the standard operating conditions (e.g., 37°C, appropriate agitation) for several hours or days.

- Monitoring: Closely monitor the uninoculated medium for any signs of growth, such as turbidity or a change in pH.

- Interpretation: The absence of growth under normal operating conditions confirms that the sterilization was effective and the vessel is free of contaminants. If growth occurs, the investigation must continue [22].

Guide 2: Managing Process Variability in Autologous Cell Production

Q: How can I reduce patient-to-patient variability in my autologous CAR-T cell therapy research process?

Inherent biological variability in starting material is a major challenge for autologous therapies. Strategies focus on controlling the manufacturing process to ensure a consistent final product.

| Source of Variability | Impact on Process | Mitigation Strategy |

|---|---|---|

| Variable Input Material | Differences in patient T-cell health, count, and functionality lead to inconsistent expansion and product quality [21]. | Implement robust cell selection and purification steps early in the process. Consider automated, closed-system technologies to improve consistency in starting material quality [23]. |

| Manual Process Steps | Operator-dependent handling introduces variability in timing, cell washing, and nutrient feeding [24]. | Adopt fully automated, closed-system bioreactors (e.g., CliniMACS Prodigy, Cocoon) that integrate cell isolation, activation, expansion, and harvesting. This minimizes human intervention [25]. |

| Uncontrolled Culture Parameters | Fluctuations in dissolved oxygen, pH, and nutrient levels affect cell growth and therapeutic cell characteristics [25]. | Utilize bioreactors with advanced sensors and closed-loop control systems. These automatically adjust parameters in real-time based on continuous feedback, ensuring a consistent growth environment [25] [26]. |

| Ill-Defined Raw Materials | Lot-to-lot differences in media, cytokines, and sera can alter cell behavior and product potency [27]. | Source GMP-grade reagents and implement rigorous raw material testing and qualification protocols to ensure lot-to-lot consistency [27]. |

Experimental Protocol: Implementing a Quality-by-Design (QbD) Approach A proactive framework to understand and control the sources of variability by linking process parameters to product quality.

- Define Critical Quality Attributes (CQAs): Identify the key characteristics of your cell product that define its safety and biological function (e.g., cell viability, specific phenotype, potency) [25].

- Identify Critical Process Parameters (CPPs): Determine the process variables (e.g., activation protocol, seeding density, agitation speed, nutrient concentration) that significantly impact your CQAs [25].

- Design of Experiments (DOE): Use statistical DOE to systematically evaluate and optimize the CPPs. This establishes a "design space" where operation will consistently produce a product meeting the desired quality profile [25] [24].

- Implement Process Controls: Establish control strategies and real-time monitoring (e.g., with PAT tools) for the CPPs to ensure the process remains within the defined design space [25].

Frequently Asked Questions (FAQs)

Q: What are the key advantages of using a closed-system automated bioreactor like the CliniMACS Prodigy or Cocoon for autologous therapy research?

A: These systems offer several critical advantages for ensuring consistency:

- Integrated Automation: They combine multiple discrete processes (cell isolation, activation, transduction, expansion, formulation) into a single, automated workflow, drastically reducing manual handling and associated variability [25].

- Closed Environment: The closed-system design minimizes the risk of contamination, a significant source of batch failure [25] [23].

- Real-time Monitoring and Control: Equipped with advanced sensors, they continuously monitor parameters like pH, dissolved oxygen, and temperature, allowing for precise control of the culture environment [25].

- Scalability and GMP Compliance: These platforms are designed to be scalable from clinical research to commercial production and are built to comply with Good Manufacturing Practice (GMP) standards [25] [27].

Q: How can I effectively monitor cell growth and viability in real-time to make better process decisions?

A: Moving beyond manual sampling is key. You can implement:

- In-line Dielectric Spectroscopy: This method measures permittivity, which correlates with the viable cell biovolume. It provides continuous, real-time data on cell growth but can be less reliable during the death phase when cell size changes [26].

- Automated On-line Sampling: Systems like the Numera can be integrated with bioreactors to automatically draw samples and transfer them to analyzers like the Cedex HiRes. This provides high-frequency, reliable data on viable cell density and viability without manual intervention, reducing contamination risk and operator error [26].

Q: We are in the early research phase. When is the right time to invest in automation?

A: Financial constraints allowing, it is advisable to consider automation as early as possible. Focusing initially on the most complex, biologically modifying steps (e.g., genetic modification, cell expansion) provides greater process control early on. Automation should ideally be in place by the time pivotal clinical trials commence to ensure robust and reproducible data for regulatory submissions [23].

The Scientist's Toolkit: Key Research Reagent Solutions

| Item / Solution | Function / Application |

|---|---|

| GMP-grade Media & Cytokines | Provides a consistent, defined, and high-quality nutrient base for cell culture, minimizing variability introduced by lot-to-l differences in raw materials [27]. |

| Serum-Free Media | Eliminates the high variability and unknown composition of fetal bovine serum (FBS), enhancing process consistency and product safety profiles [27]. |

| Single-Use Bioreactor Assemblies | Pre-assembled, sterile flow paths (including tubing, bags, and sensors) for single-use bioreactors. They reduce cross-contamination risk, eliminate cleaning validation, and increase operational flexibility [25] [28]. |

| Closed-System Sterile Connectors | Enable the aseptic connection of fluid pathways within a closed process, maintaining a sterile environment during additions or transfers [28]. |

| Process Analytical Technology (PAT) | A category of tools and software (e.g., Raman spectroscopy, advanced sensors) for real-time monitoring of critical process parameters to ensure process control and facilitate real-time release testing [25] [26]. |

The Role of AI and Digital Twins in Predictive Process Control and Real-Time Monitoring

Fundamental Concepts FAQ

Q1: What is a Digital Twin in the context of autologous cell therapy manufacturing? A Digital Twin is a virtual replica of a physical bioprocess, such as CAR-T cell expansion. It uses real-time data from sensors and IoT devices to mimic the behavior and performance of its real-world counterpart. This allows researchers to monitor, simulate, and analyze the entire production process in a virtual environment, enabling predictive control and optimization [29] [30] [31].

Q2: How does AI integrate with Digital Twins for predictive process control? AI, particularly machine learning (ML), analyzes the vast amounts of data generated by the Digital Twin. It identifies complex patterns to predict process outcomes, such as final cell viability or differentiation efficiency. This creates a closed-loop control system where the AI can proactively suggest or even implement adjustments to the bioprocess parameters to maintain quality and improve yield [32] [33] [30].

Q3: What are the key benefits of using these technologies for autologous therapies? The primary benefits include:

- Improved Consistency: Mitigates patient-to-patient variability in starting materials [33] [30].

- Enhanced Monitoring: Enables real-time, non-invasive monitoring of Critical Quality Attributes (CQAs) [30].

- Predictive Maintenance: Anticipates equipment failures to avoid costly downtime [29] [31].

- Accelerated Development: "In-silico" simulation experiments speed up process development and reduce raw material costs [30] [31].

Q4: What is the difference between a simulation and a Digital Twin? While both use models, a simulation typically runs predefined scenarios in a static, virtual-only environment. A Digital Twin is dynamically connected to a specific physical asset via a continuous, real-time data flow, allowing it to reflect the current state of the process and send insights back to the physical system [31].

Troubleshooting Guides

Guide 1: Addressing Data Quality and Integration Issues

Problem: The Digital Twin model produces inaccurate predictions or fails to synchronize with the physical bioreactor.

| Step | Action & Diagnosis | Solution |

|---|---|---|

| 1. Identify | Examine system logs for error messages like "Invalid input format" or "API request failed." Check for failed data transmissions [34]. | Implement comprehensive logging to capture input data, model parameters, and intermediate outputs for tracing [35]. |

| 2. Analyze | Examine the data pipeline from sensor to model. Verify the execution path and check for misconfigured triggers or conditions that pre-process the data [34]. | Use visualization tools to inspect raw sensor data for anomalies or missing values. Validate that all data sources are correctly configured and calibrated [35]. |

| 3. Test & Isolate | Run the workflow with standardized, synthetic input data with known outputs. selectively disable specific data streams to pinpoint the source of the error [34] [35]. | Break down the data pipeline into smaller components (e.g., sensor data collection, data transmission, data pre-processing) and test each one separately [34]. |

| 4. Implement Fix | If the issue is with input data, clean and re-format it to meet required standards. If the issue is a workflow misconfiguration, adjust the relevant data processing steps [34]. | For persistent model inaccuracies, retrain the AI model with corrected and validated data, or adjust its hyperparameters [34] [33]. |

| 5. Validate | Confirm the fix by running the Digital Twin with a diverse set of validation data, ensuring it now operates smoothly and produces expected outputs [34]. | |

| 6. Monitor | Continuously monitor data quality metrics and system logs to catch new issues early and ensure long-term stability [34]. |

Guide 2: Troubleshooting AI Model Performance and Drift

Problem: The AI model's predictive performance degrades over time, leading to suboptimal process control.

| Step | Action & Diagnosis | Solution |

|---|---|---|

| 1. Identify | Monitor key performance metrics like prediction error rates or drift in key output parameters. Look for unexpected or inconsistent process outputs [34] [35]. | Utilize an analytics dashboard for real-time insights into model performance and to spot trends and anomalies [35]. |

| 2. Analyze | Investigate potential causes, such as changes in raw material variability (e.g., patient cell characteristics) or shifts in the underlying process dynamics that the model was not trained on [33] [30]. | Use Explainable AI (XAI) techniques like SHAP or LIME to understand which input features the model is relying on and if these have changed [35]. |

| 3. Test & Isolate | Conduct A/B testing by running the new model in parallel with the previous stable version to isolate the impact of the change [35]. | Create a controlled simulation environment to test the model's response to edge cases and new variability patterns [33]. |

| 4. Implement Fix | Update the AI model by retraining it with recent process data that reflects the new variability. For a hybrid approach, adjust the data-driven model components while retaining the foundational mechanistic model [30]. | |

| 5. Validate | Thoroughly validate the updated model using historical and new test data to ensure it resolves the performance issue without introducing new errors [34]. | |

| 6. Monitor | Establish ongoing monitoring of model performance and data distributions to proactively detect and address future model drift [34] [35]. |

Experimental Protocols & Methodologies

Protocol 1: Developing a Hybrid Digital Twin for a Bioreactor

Aim: To create a hybrid Digital Twin for the real-time monitoring and prediction of cell density and viability in a CAR-T cell expansion process.

Methodology:

System Definition and Sensor Integration:

Model Development (Hybrid Approach):

- Mechanistic Model Component: Develop a model based on convection-diffusion equations to simulate the spatial distribution of nutrients and metabolites in the bioreactor. This component is grounded in established physical laws [30].

- Data-Driven Model Component: Use machine learning (e.g., a convolutional neural network) on the daily label-free images to generate maps highlighting live cells, local cell density, and pluripotency levels. This AI acts as a "soft sensor" for CQAs that are difficult to measure directly in real-time [33] [30].

- Integration: The outputs of both models are combined into a unified hybrid Digital Twin that provides a comprehensive view of the bioprocess.

Validation and Deployment:

- Validate the Digital Twin's predictions against offline analytical measurements (e.g., flow cytometry for cell identity, trypan blue exclusion for viability).

- Once validated, deploy the Digital Twin for real-time monitoring and use its predictions to inform a closed-loop control strategy, such as automatically adjusting perfusion rates to maintain optimal cell density [32] [30].

The following workflow diagram illustrates this hybrid modeling approach:

Protocol 2: Implementing a Closed-Loop Control System with AI

Aim: To establish an AI-driven closed-loop control system for maintaining healthy cell cultures by proactively removing unwanted cells.

Methodology:

Data Acquisition and Mapping:

- The system performs daily, label-free imaging of the entire cell culture.

- An AI algorithm analyzes these images to generate detailed maps identifying live cells, dead cells, local cell density, and pluripotency levels [33].

Analysis and Decision Making:

- The AI analyzes the maps to identify regions with unwanted cell types or unhealthy colonies that could hinder the growth of the target cell population.

- Based on predefined quality thresholds, the system decides which cells to remove.

Precision Intervention:

- The AI-generated maps guide a proprietary laser system.

- The laser precisely targets and removes unwanted cells by absorbing energy in a specialized coating beneath the cells, generating mechanical bubbles that eliminate the target cells without affecting neighboring healthy cells [33].

Validation and Iteration:

- The process is continuously validated through subsequent imaging and AI analysis.

- A multi-agent reinforcement learning model, trained in a simulated environment, can be used to optimize the cell culture management strategy, learning to manage multiple colonies within a confined space to avoid collisions and overgrowth [33].

The logical flow of this autonomous control system is shown below:

The Scientist's Toolkit: Essential Research Reagent Solutions

The following table details key reagents, technologies, and software solutions critical for experiments involving AI and Digital Twins in cell therapy.

| Item / Solution | Function / Application |

|---|---|

| CRISPR/Cas9 & Plasmids | Gene editing tools used for precise modification of T-cells to express Chimeric Antigen Receptors (CARs) [36]. |

| Bioreactors & Closed-System Culture Platforms | Facilitate the growth and expansion of genetically modified T-cells under controlled, automated conditions [32] [36]. |

| Flow Cytometer (e.g., CytoFLEX) | An analytical tool essential for quality control, used to confirm CAR-T cell identity and characterize cell subpopulations [32] [36]. |

| Cell Viability Analyzer (e.g., Vi-CELL BLU) | Automates cell viability and count analysis using the Trypan Blue exclusion method, a critical quality control test [36]. |

| Process Information Management System (PIMS) | Cloud-native, compliant software that creates a contextualized data backbone of all manufacturing process and quality data across batches, essential for training AI models [36]. |

| Semi-Automated Devices (e.g., Cocoon, Prodigy) | Reduce hands-on production time and risk of contamination for autologous therapy manufacturing, generating standardized process data [32]. |

| AI-powered Imaging & Analysis Software | Provides label-free, non-invasive analysis of cell cultures, generating data on cell count, viability, and morphology for the Digital Twin [33]. |

Adopting Point-of-Care and Decentralized Manufacturing Models with Centralized QMS Oversight

Point-of-care (POC) and decentralized manufacturing represent a paradigm shift in producing autologous cell therapies, moving production from large, centralized facilities to multiple, smaller sites close to the patient. This model is particularly vital for autologous cell therapies, where a patient's own cells are harvested, engineered, and reinfused. The traditional centralized approach faces significant challenges with complex logistics, cryopreservation, and lengthy "vein-to-vein" times that can exceed three weeks [37] [38] [39]. Decentralized manufacturing addresses these by locating production at or near the treatment center, drastically reducing turnaround time and simplifying cold chain logistics [37] [40].

However, distributing manufacturing across multiple locations introduces risks of process variability. A Centralized Quality Management System (QMS) is the critical framework that ensures product quality, safety, and consistency across all manufacturing sites, providing unified regulatory oversight and standardizing operations [41]. This hybrid approach—decentralized production with centralized quality control—enables wider patient access without compromising the rigorous standards required for advanced therapy medicinal products (ATMPs) [41].

Troubleshooting Guides

Common Workflow Challenges and Solutions

Table: Troubleshooting Common POC Manufacturing Challenges

| Problem Area | Specific Issue | Potential Causes | Recommended Solutions |

|---|---|---|---|

| Cell Processing | Low cell viability post-thaw | Improper thawing technique; osmotic shock [42]. | Thaw cells quickly (<2 mins at 37°C); use pre-warmed medium; add medium drop-wise to dilute cryoprotectant [43] [42]. |

| Cell Processing | Poor cell attachment | Matrix coating dried; incorrect seeding density; lack of attachment factors [43] [42]. | Shorten time between coating and cell seeding; verify lot-specific seeding density; use appropriate coating matrix [43] [42]. |

| Process Control | High batch-to-batch variability | Manual, open processing steps; patient-to-patient input material variation [38] [39]. | Implement automated, closed-system bioprocessing; use standardized protocols managed by the Centralized QMS [41] [38] [39]. |

| Contamination Control | Microbial contamination in non-cleanroom settings | High microbial burden in hospital environments; open system processing [44]. | Employ isolator-based closed systems (e.g., positive pressure isolators with VHP decontamination) [44]. |

| Logistics & Timing | Short product shelf-life | Fresh cell products; prolonged QC testing [41]. | Implement rapid, real-time QC testing (e.g., inline analytics); coordinate scheduling via centralized QMS [44] [41]. |

Quality Management and Regulatory Hurdles

Table: Troubleshooting QMS and Regulatory Compliance

| Challenge | Root Cause | Corrective and Preventive Actions |

|---|---|---|

| Demonstrating product comparability across sites | Inherent facility-to-facility differences; non-identical equipment [41]. | Perform extensive process validation and analytical method qualification at each site. The Control Site must hold and maintain the POCare Master File to demonstrate consistency [41]. |

| Regulatory ambiguity for multi-site production | Evolving regulatory frameworks for decentralized models [41] [38]. | Proactively engage with regulators (FDA, EMA, MHRA) through emerging programs like the FDA's Emerging Technology Program and FRAME initiative [41]. |

| Maintaining training consistency | High staff turnover at POC sites; varying levels of GMP expertise [44] [41]. | Establish an overarching, standardized training platform managed by the Control Site. Utilize an Electronic QMS (eQMS) for training records and standard procedures [41] [45]. |

| Managing deviations and non-conformances | Paper-based QMS leading to poor traceability and delayed reporting [45]. | Implement an eQMS to centralize and automate deviation tracking, corrective actions, and change management, ensuring real-time visibility for the Quality Unit [45]. |

Frequently Asked Questions (FAQs)

Q1: What are the main technological enablers for decentralized manufacturing of autologous cell therapies? The shift to decentralized manufacturing is made feasible by several key technologies:

- Automated Closed Systems: Platforms like the

CliniMACS ProdigyorLonza Cocoonintegrate multiple manufacturing steps (isolation, activation, transduction, expansion) within a single-use, disposable kit, minimizing manual intervention and contamination risk [39]. - Isolator Technology: Sealed containment devices provide an ISO Class 5 environment within a non-classified hospital room. They use glove ports, rapid transfer ports, and vaporized hydrogen peroxide (VHP) decontamination to maintain asepsis, protecting the product from the external environment [44].

- Digital Integration: Software like

CTS Cellmationenables digital automation and data collection. When integrated with an eQMS, this allows for real-time monitoring and centralized oversight of distributed processes [37] [41].

Q2: How does a Centralized QMS (Control Site) function in a decentralized network? The Control Site acts as the regulatory and quality nexus for all decentralized manufacturing sites [41]. Its core functions include:

- Holding the single Manufacturing License and maintaining the central POCare Master File for the product.

- Serving as the primary point of contact for regulatory agencies (e.g., FDA, EMA).

- Providing overarching Quality Assurance and employing the Qualified Person (QP) responsible for batch certification and release.

- Managing a centralized eQMS for deviations, change control, and training records across the network [41] [45].

Q3: Are there real-world examples of successful decentralized CAR-T cell manufacturing?

Yes, several academic institutions and clinical trials have demonstrated the feasibility of POC CAR-T manufacturing. For instance, a study by Maschan et al. reported robust safety and efficacy in patients with B-cell malignancies treated with fresh, place-of-care manufactured anti-CD19 CAR-T cells produced at two different locations using the CliniMACS Prodigy platform, eliminating the need for cryopreservation [41]. Other studies, such as one using the ARI-0001 platform, have shown manufacturing times of 8-11 days, which is a significant reduction compared to traditional centralized models [39].

Q4: What is a key advantage of using a shortened (e.g., 24-hour) manufacturing process? Shortened processes aim to preserve a less differentiated T-cell phenotype. Research shows that CAR-T cells manufactured in 24 hours exhibit a higher proportion of T stem cell memory (TSCM) cells (CD45RA+/CCR7+), which are associated with improved long-term persistence and anti-tumor activity in vivo, compared to cells expanded over 7 days that show a more differentiated and potentially exhausted phenotype [37].

Q5: How can we ensure sterility without a full GMP cleanroom at every hospital site? Isolator-based systems are designed for this exact scenario. A positive pressure isolator creates its own critical processing environment (ISO Class 5) independently of the background room. With integrated decontamination cycles and closed processing, it provides sterility assurance equivalent to or greater than a traditional biological safety cabinet within a cleanroom, but with a smaller footprint and lower facility requirements [44].

The Scientist's Toolkit: Essential Research Reagent Solutions

Table: Key Reagents and Instruments for POC Cell Therapy Manufacturing

| Item Name | Function/Application | Key Feature for Decentralized Manufacturing |

|---|---|---|

| CTS Detachable Dynabeads CD3/CD28 | One-step isolation and activation of T cells [37]. | Active-release feature allows for bead removal at any point, preventing T-cell overactivation and exhaustion, which is crucial for shortened processes [37]. |

| LV-MAX Lentiviral Production System | Production of lentiviral vectors for cell transduction [37]. | Provides a consistent and scalable system for generating the viral vectors needed for genetic modification at the POC [37]. |

| CTS DynaCellect Magnetic Separation System | Automated cell separation and bead detachment [37]. | An automated, closed-system instrument that integrates with the detachable beads, reducing manual steps and variability [37]. |

| CTS Rotea Counterflow Centrifugation System | Cell washing and concentration [37]. | Provides a low-shear environment that ensures high cell recovery and viability, which is critical when working with precious patient samples [37]. |

| Gibco CTS Cellmation Software | Digital automation and process control [37]. | Enables closed, automated instrumentation and software control, reducing manual touchpoints and allowing for digital record-keeping aligned with QMS needs [37]. |

| Positive Pressure Isolator | Physical barrier for aseptic processing [44]. | Enables GMP-compliant manufacturing in a non-classified hospital room through a sealed, decontaminated environment with glove ports [44]. |