Strategies for Cost-Effective Clinical Grade Exosome Manufacturing: Scaling Production for Therapeutic Applications

This article addresses the critical challenge of high production costs in large-scale, clinical-grade exosome manufacturing, a major barrier to the commercialization of exosome-based therapeutics.

Strategies for Cost-Effective Clinical Grade Exosome Manufacturing: Scaling Production for Therapeutic Applications

Abstract

This article addresses the critical challenge of high production costs in large-scale, clinical-grade exosome manufacturing, a major barrier to the commercialization of exosome-based therapeutics. Aimed at researchers, scientists, and drug development professionals, it provides a comprehensive analysis of the current landscape, from foundational cost drivers and scalability bottlenecks to innovative methodological solutions in isolation and purification. The content further explores advanced optimization strategies, including the integration of AI and automation, and concludes with essential frameworks for process validation and comparative economic analysis to guide the development of scalable, reproducible, and cost-effective production pipelines.

The High Cost of Innovation: Understanding Exosome Manufacturing Economics and Scalability Hurdles

Market Growth and the Pressing Need for Cost-Effective Production

Frequently Asked Questions (FAQs) on Cost-Effective Exosome Manufacturing

1. What are the primary cost drivers in large-scale exosome production? The primary costs originate from both upstream (cell culture) and downstream (purification) processes. Upstream, expenses are driven by the need for large quantities of high-quality, xeno-free culture media and efficient bioreactor systems to maximize cell numbers [1]. Downstream, the complexity of isolating and purifying exosomes at a clinical grade, using techniques like Tangential Flow Filtration (TFF) and chromatography, constitutes a significant portion of the total cost, with estimates as high as $1,000,000 per manufacturing lot [1].

2. How can we increase exosome yield from parent cells? Yield can be increased through two main strategies:

- Genetic Engineering: Introducing specific genes (e.g., STEAP3, syndecan-4, L-aspartate oxidase) into parent cells can enhance exosome biogenesis and release, reportedly increasing production by up to 40-fold [2].

- Cell Preconditioning: Exposing parent cells to stressors like moderate hypoxia or treating them with certain cytokines (e.g., thrombin, adiponectin) can upregulate exosome biogenesis pathways, thereby increasing vesicle output [2].

3. What is the most scalable method for exosome purification? While ultracentrifugation (UC) is the lab-scale gold standard, it is not suitable for large-scale manufacturing due to low yield, long processing times, and potential for vesicle damage [3]. Tangential Flow Filtration (TFF) is a more scalable alternative that offers higher recovery yields and better removal of contaminating proteins like albumin [3]. For high purity, TFF is often combined with chromatographic methods like Anion Exchange Chromatography (AIEX) or Size-Exclusion Chromatography (SEC), which can efficiently purify exosomes in a scalable manner [3].

4. Why is there a lack of standardization in exosome manufacturing, and how does it impact cost? The field currently lacks universally accepted protocols for isolation, purification, and characterization [4] [5]. This leads to batch-to-batch variability, challenges in reproducing results, and difficulties in obtaining regulatory approval. The inconsistency increases development costs and risks, as each manufacturer must establish and validate its own processes, hindering widespread clinical adoption [5].

5. What are the key quality control metrics for clinical-grade exosomes? Robust quality control is essential. Key metrics include [3] [6]:

- Particle Characterization: Size distribution (typically 30-150 nm) and concentration, measured via Nanoparticle Tracking Analysis (NTA) or similar.

- Identity/Purity: Presence of specific transmembrane (e.g., CD63, CD81) and cytoplasmic (e.g., TSG101, ALIX) protein markers, and absence of negative markers (e.g., albumin) via Western Blot or flow cytometry [2].

- Potency: Assessment of biological activity, which may include RNA-to-protein ratios or functional cell-based assays [6].

- Safety: Tests for sterility, mycoplasma, and endotoxins [6].

Troubleshooting Guides

Problem 1: Low Exosome Yield in Upstream Bioprocessing

Potential Causes and Solutions:

| Cause | Diagnostic Steps | Solution |

|---|---|---|

| Suboptimal Cell Expansion | Monitor population doubling time and cell viability. Compare growth rates to established benchmarks. | Implement a high-performance, xeno-free culture medium designed for rapid cell expansion to shorten process time and increase final cell density [1]. |

| Inefficient Bioreactor Process | Analyze dissolved oxygen (DO), pH, and metabolite levels. Check for inadequate nutrient mixing or shear stress. | Transition from planar flask-based culture to scalable bioreactor systems (e.g., hollow-fiber, microcarrier-based). Optimize bioreactor parameters for your specific cell line [3]. |

| Inadequate Collection Phase | Analyze the particle-to-cell ratio after the collection phase. | Exchange growth medium for a specialized, low-particulate collection medium (e.g., RoosterCollect-EV) and optimize the collection time (often 1-3 days) to maximize yield while maintaining quality [1]. |

Detailed Protocol: Preconditioning with Hypoxia to Enhance Yield

- Objective: To increase exosome production from Mesenchymal Stem Cells (MSCs) by upregulating biogenesis pathways through hypoxic preconditioning [2].

- Materials:

- Confluent flask of MSCs (e.g., Passage 4-6).

- Standard cell culture incubator (normoxic: 20% O₂, 5% CO₂).

- Hypoxia chamber or tri-gas incubator (preconditioning: 1-3% O₂, 5% CO₂, balanced N₂).

- Xeno-free basal medium.

- Purification equipment (e.g., TFF system).

- Methodology:

- Split MSCs and seed them at a standard density.

- Allow cells to adhere overnight in a normoxic incubator.

- Replace the medium with fresh, pre-warmed xeno-free basal medium.

- Transfer the cell culture flask to the hypoxia chamber and culture for 24-48 hours.

- After preconditioning, collect the conditioned medium.

- Proceed immediately to exosome purification using your standard downstream process (e.g., TFF).

- Expected Outcome: Studies report that hypoxic preconditioning can upregulate genes like HIF-1α, Rab27a, and ALIX, leading to a significant increase in exosome secretion compared to normoxic conditions [2].

Problem 2: High Impurity and Low Quality in Downstream Processing

Potential Causes and Solutions:

| Cause | Diagnostic Steps | Solution |

|---|---|---|

| Carryover of Culture Medium Impurities | Perform protein quantification (e.g., BCA assay) and analyze samples via Western Blot for common contaminants like bovine serum albumin (BSA). | Implement a thorough wash step, exchanging growth medium for a defined, low-protein collection medium before the final production phase to eliminate process-related impurities [1]. |

| Use of Non-Scalable Purification Methods | Evaluate the recovery yield and processing time. Ultracentrifugation is a key indicator. | Replace ultracentrifugation with a scalable purification train. A recommended approach is an initial concentration step using Tangential Flow Filtration (TFF), followed by a polishing step using Anion Exchange Chromatography (AIEX) or Size-Exclusion Chromatography (SEC) to achieve high purity [3]. |

| Exosome Aggregation or Damage | Use NTA to check for an increase in particle size and a wide size distribution. | Avoid harsh mechanical forces. For TFF, optimize transmembrane pressure and cross-flow rates. For storage, use cryoprotectants and avoid multiple freeze-thaw cycles. |

Detailed Protocol: TFF and AIEX for Scalable Purification

- Objective: To concentrate and purify exosomes from conditioned medium with high yield and purity, suitable for clinical-grade manufacturing [3].

- Materials:

- Conditioned cell culture medium (cell-free).

- TFF system with a cartridge (e.g., 100-500 kDa MWCO).

- AIEX system (e.g., monolithic column).

- Binding Buffer (e.g., low salt, ~50 mM NaCl, pH 7.4).

- Elution Buffer (e.g., high salt, ~500-765 mM NaCl, pH 7.4) [3].

- PBS or a suitable formulation buffer for diafiltration.

- Methodology:

- Concentration with TFF: Pass the conditioned medium through the TFF system to concentrate the exosomes. Perform diafiltration with Binding Buffer to exchange the medium and remove contaminants.

- AIEX Purification: Load the concentrated retentate onto the pre-equilibrated AIEX column.

- Wash: Wash the column with several column volumes of Binding Buffer to remove unbound proteins and impurities.

- Elute: Elute the purified exosomes using a linear or step gradient of Elution Buffer.

- Formulation: Pool the exosome-containing fractions and perform a final diafiltration into PBS or a storage buffer using the TFF system.

- Expected Outcome: This combination can achieve a 100-fold higher concentration efficiency than UC and effectively remove contaminating proteins and non-ionic surfactants, resulting in high-purity exosomes in a process that takes only a few hours [3].

The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function in Exosome Research |

|---|---|

| Xeno-Free Cell Culture Medium | Supports the expansion of parent cells (e.g., MSCs, HEK293) without introducing animal-derived contaminants, which is critical for clinical-grade production [1]. |

| RoosterCollect-EV / Defined Collection Media | A low-particulate, serum-free medium used specifically during the exosome production phase to collect vesicles with minimal process-related impurities [1]. |

| Microcarriers | Provide a surface for adherent cells to grow in bioreactors, dramatically increasing the available surface area and thus the cell yield in a scalable suspension culture system [3]. |

| Super Absorbent Polymer (SAP) Beads | A novel technology that absorbs small molecules like water but expels and concentrates extracellular vesicles, offering a potential single-step method for enriching EVs with high purity [3]. |

| Nanoparticle Tracking Analyzer | An essential instrument for characterizing exosomes by determining their particle size distribution and concentration in a preparation [2]. |

Quantitative Data on Exosome Manufacturing and Markets

Table 1: Market Growth Projections for Exosome Manufacturing and Isolation

| Market Segment | 2024/2025 Base Size | Projected 2030/2034 Size | CAGR (Compound Annual Growth Rate) | Source |

|---|---|---|---|---|

| Exosome Manufacturing Services | ~$2.5 - $3 Billion (2023/2024) | ~$10 Billion (2030) | 25-30% | [7] |

| Exosome Isolation Market | $462 Million (2025) | $1.24 Billion (2034) | 11.64% | [8] |

| Exosome Development & Manufacturing Services | $24.2 Million (2025) | $127.4 Million (2035) | 18% | [5] |

Table 2: Cost and Yield Comparison of Upstream Process Platforms

| Process Platform | Time to 100M hMSCs | Total Process Time (for ~5e11 EVs) | Extracellular Vesicle Yield per Process Day | Estimated Cost per Dose Regimen |

|---|---|---|---|---|

| Traditional Materials | 27 days | 30 days | Low (Baseline) | High (~$8,000) [1] |

| High-Performance Xeno-Free Platform | 10 days | 13 days | ~50x higher than Traditional | Significantly Lower [1] |

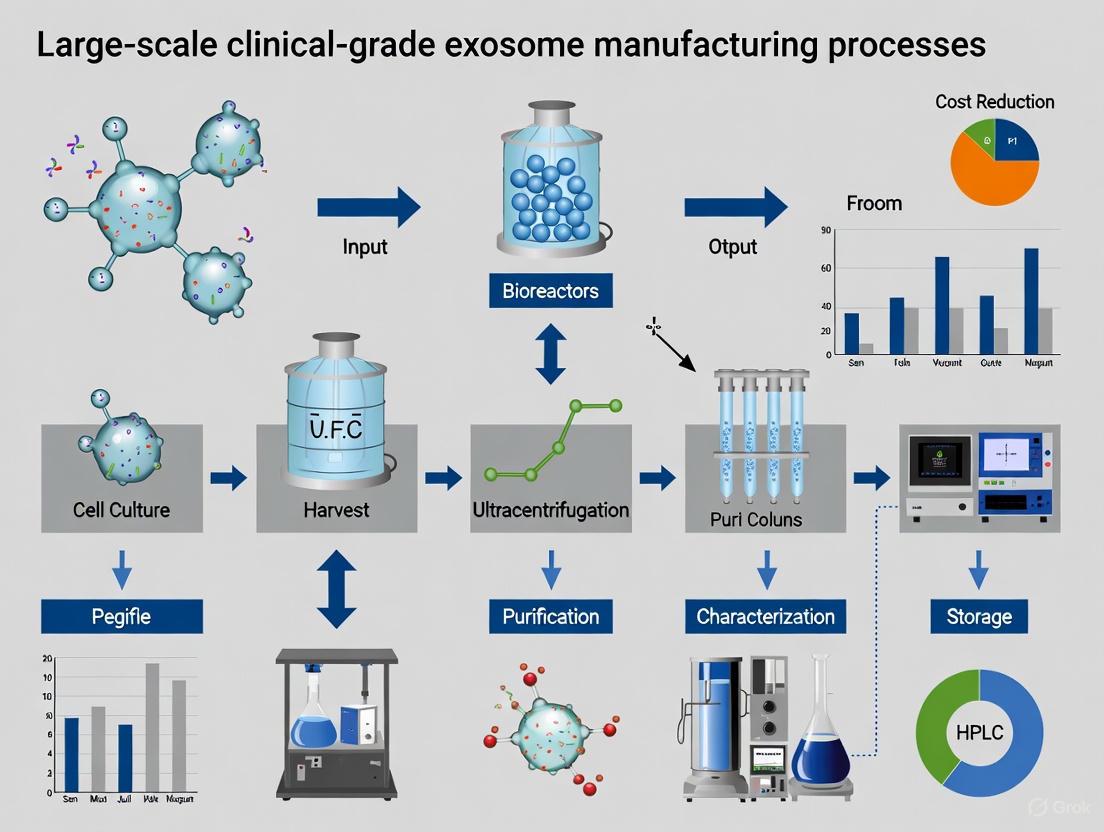

Process Visualization Workflows

Scalable Upstream Process Workflow

Integrated Downstream Purification Train

The exosome research market is experiencing rapid growth, projected to expand from USD 225.72 million in 2025 to USD 961.41 million by 2034, with a robust compound annual growth rate (CAGR) of 17.47% [9]. This expansion is primarily driven by increasing understanding of exosomes' therapeutic potential in various disease areas, including cancer, neurodegenerative diseases, and autoimmune disorders [10]. However, the transition from research to clinical application is hampered by significant cost drivers that make large-scale production financially challenging. The high cost of exosome production remains a major restraint, compounded by complexity in characterization, stringent regulatory requirements, and lack of standardization across manufacturing processes [10]. This technical support center document aims to deconstruct these cost drivers and provide actionable troubleshooting guidance to help researchers optimize their manufacturing processes while controlling expenses.

Quantitative Analysis of Major Cost Drivers

Understanding the financial landscape of exosome manufacturing requires careful analysis of the factors that most significantly impact production costs. The following table summarizes the primary cost drivers and their relative impact based on current market analysis:

Table 1: Primary Cost Drivers in Exosome Manufacturing

| Cost Driver | Financial Impact | Impact Timeline | Geographic Relevance |

|---|---|---|---|

| Stringent GMP Demands Elevating Manufacturing Complexity & Cost [11] | Significant impact on operational expenses | Short term (≤ 2 years) | Global, with higher impact in regulated markets (North America, Europe) |

| Lack of Standardized Characterization Protocols Undermining Reproducibility [11] | Moderate to high impact due to need for repeated experiments | Medium term (2-4 years) | Global |

| High R&D Costs and Complex Regulatory Pathways [12] | High impact on initial investment | Medium term (2-4 years) | Global |

| Scaling Up Production for Clinical Trials and Commercial Applications [10] | Variable impact based on production scale | Long term (≥ 4 years) | Global |

The financial implications of these cost drivers are substantial. Scaling from benchtop to Good Manufacturing Practice (GMP) requires closed-system bioreactors, sterile-filtration controls, and validated analytics, creating significant capital requirements [11]. Smaller innovators often outsource production, increasing cash burn and potentially delaying milestones. Meanwhile, heterogeneous isolation methods generate vesicle preparations with divergent particle counts, size distributions, and bioactivity, leading to reproducibility issues that increase costs through repeated experiments and failed trials [11].

Technical FAQs: Troubleshooting Costly Production Challenges

Low Yield and Scalability Issues

Q: My exosome isolation yields are substantially lower than expected when scaling up from research to clinical scale. How can I improve yields without dramatically increasing costs?

A: Low yields during scale-up typically result from suboptimal production or inefficient isolation. To address this:

- Implement bioreactor systems: Hollow fiber bioreactors can increase yields by up to 38-fold compared to flask cultures [13]. While requiring initial capital investment, these systems provide significant long-term cost savings per unit of exosome produced.

- Optimize cell culture conditions: Research indicates that applying hypoxic conditions to mesenchymal stem cells (MSCs) upregulates exosome biogenesis genes (HIF-1α, ALIX, TSG101, Rab27a, and Rab27b), significantly increasing exosome production without additional reagent costs [2].

- Genetic engineering approaches: Introducing specific genes (STEAP3, syndecan-4, and L-aspartate oxidase fragment) into parent cells has demonstrated a 40-fold increase in exosome production with no change in exosome size [2].

- Ultrasound stimulation: Applying ultrasound to producer cells can enhance exosome production via a calcium-dependent mechanism, resulting in an 8-10-fold increase in yield [2].

Process Efficiency and Contamination

Q: The isolated exosomes appear to be contaminated with non-exosomal proteins and other impurities. How can I ensure purity without adding expensive purification steps?

A: Contamination issues typically arise from inadequate purification methods:

- Optimize isolation protocols: Research demonstrates that repeated ultracentrifugation steps can reduce the quality of exosome preparations leading to lower exosome yield and purity [14]. Concentration of cell culture conditioned media using ultrafiltration devices results in increased vesicle isolation when compared to traditional ultracentrifugation protocols.

- Implement size-exclusion chromatography (SEC): Studies show that SEC provides superior purity compared to precipitation methods, which co-isolate contaminating proteins [14]. While requiring specialized equipment, SEC provides better long-term value by reducing downstream processing costs.

- Utilize density gradient purification: OptiPrep density gradient isolation provides the highest purification of exosomes from cell culture conditioned media, though it is comparable to SEC for protein exosome markers [14].

Characterization and Quality Control Challenges

Q: Characterization and quality control processes are consuming substantial time and resources. Are there more efficient approaches to ensure batch-to-batch consistency?

A: Efficient characterization is essential for controlling costs:

- Implement orthogonal characterization methods: Instead of relying on a single method, use a combination of nanoparticle tracking analysis (NTA), transmission electron microscopy (TEM), and western blotting with specific exosomal markers (CD63, CD81, CD9) to ensure comprehensive characterization without redundant costs [15].

- Standardize protein quantification: Be aware that protein concentration does not always correlate well with exosome content [16]. Instead, standardize exosome harvest conditions and use bead-based methods to estimate exosome amounts more reliably.

- Leverage surface marker analysis: Use specific antibodies against common exosome surface markers (CD63, CD81, CD9) for reliable identification, but note that some cell lines release exosomes lacking these markers (e.g., Jurkat cells are CD9 negative) [16].

Scalable Production Methodologies: Protocols and Procedures

Bioreactor-Based Production Workflow

Large-scale production of exosomes using bioreactor systems represents the most cost-effective approach for clinical-grade manufacturing. The following diagram illustrates the optimized workflow:

Bioreactor Production Workflow

Detailed Protocol:

- Bioreactor Preparation: Coat a 200 mL hollow-fiber bioreactor with 0.005% human fibronectin in PBS for 4 hours to aid cell adherence [13].

- Cell Seeding: Seed MSCs at 3.0 × 10⁷ cells into the bioreactor and allow to attach for 24 hours [13].

- Expansion Phase: Expand cells by increasing daily media input feeding rate to compensate for growing cell numbers. Monitor expansion via glucose consumption and lactate production (approximately 1.6 × 10⁻⁸ mmol/day) [13].

- Peak Expansion: Typically achieved after 6 days in bioreactor, representing approximately 5 × 10⁸ cells [13].

- Media Exchange: After peak expansion, wash out expansion media with PBS and replace with 200 mL serum-free media [13].

- Conditioned Media Collection: Collect conditioned media from inner loop outlet at 24-hour intervals (24H, 48H, 72H, and up to 96H) [13].

- Exosome Isolation: Isolate exosomes using ultracentrifugation - initial low-speed spin (2,000 × g at 4°C for 20 minutes) to remove cell debris, followed by ultracentrifugation (100,000 × g avg at 4°C for 2 hours) [13].

- Resuspension and Storage: Resuspend exosomes in PBS, aliquot, and store at -80°C [13].

Yield Enhancement Strategies

Table 2: Experimental Yield Enhancement Techniques

| Method | Cell Type | Suggested Mechanism | Yield Improvement |

|---|---|---|---|

| Genetic Engineering (EXOtic device) [2] | Engineered HEK293 | Overexpression of STEAP3, syndecan-4, L-aspartate oxidase | 40-fold increase |

| Hypoxic Conditions [2] | MSC | Upregulation of HIF-1α, ALIX, TSG101, Rab27a, Rab27b | Significant increase (study-dependent) |

| Ultrasound Stimulation [2] | U87-MG human glioblastoma, A549 cells | Calcium-dependent mechanism, upregulation of ALIX, TSG101, CD63 | 8-10-fold increase |

| LPS Priming [13] | MSC | Enhanced educational capacity for monocytes, improved therapeutic potency | Improved functionality at similar yields |

| 3D Culture Systems [2] | Human induced pluripotent stem cells | Altered mRNA expression of ALIX, TSG101, ADAM10, CD63, Syntenin-1 | Varies by system |

Research Reagent Solutions for Cost-Effective Production

Table 3: Essential Research Reagents and Their Functions

| Reagent/Category | Function | Cost-Saving Considerations |

|---|---|---|

| Serum-Free Media [13] | Supports exosome production without serum-derived contaminants | Enables downstream purification; reduces contamination-related losses |

| Ultracentrifugation Equipment [14] | Gold standard for exosome isolation | High initial investment but lower per-unit cost at scale |

| Size-Exclusion Chromatography [14] | High-purity exosome isolation | Superior purity reduces downstream processing costs |

| Immunoaffinity Capture Beads [16] | Specific exosome isolation using surface markers | Higher specificity but increased cost; ideal for specific applications |

| Trehalose [13] | Cryoprotectant for exosome storage | Maintains exosome integrity during storage, reducing batch losses |

| LPS [13] | Priming agent to enhance exosome potency | Enhances therapeutic effect without increasing production volume |

| OptiPrep Density Gradient [14] | High-purity exosome purification | Provides exceptional purity for sensitive applications |

Cost Optimization Roadmap and Future Perspectives

The future of cost-effective exosome manufacturing will be shaped by several emerging technologies and approaches. Automation and process optimization for large-scale production represent a key trend that will substantially reduce labor costs and improve consistency [10]. Artificial intelligence can reshape the market by enabling predictive modeling of exosome behavior, supporting virtual simulations for drug testing, and reducing reliance on traditional trial-and-error methods [9]. Additionally, development of standardized quality control frameworks will help reduce costs associated with characterization and validation [10].

Microfluidics-based isolation is projected to grow rapidly as it enables compact, cost-effective, and scalable exosome separation suitable for clinical and laboratory settings [9]. Its ability to integrate multiple processes, such as sorting, detection, and analysis on a single chip, reduces time and labor requirements. Furthermore, increasing focus on harmonized protocols and reference materials will help minimize reproducibility issues that currently drive up research costs [4].

As the regulatory landscape evolves, with the U.S. FDA providing clearer guidance on critical quality attribute testing and release criteria, the costs associated with regulatory compliance are expected to decrease through more standardized pathways [11]. This clarity reduces approval risk and attracts late-stage capital, ultimately driving down the cost of capital for exosome manufacturing ventures.

By implementing the strategies outlined in this technical support document, researchers and manufacturing professionals can systematically address the major cost drivers in clinical-grade exosome production while maintaining quality and compliance standards.

Frequently Asked Questions (FAQs)

Q1: What specific limitations of ultracentrifugation hinder large-scale clinical production of exosomes?

Ultracentrifugation (UC), the classical method for exosome isolation, faces several critical bottlenecks that impede its use in large-scale clinical manufacturing:

- Low Yield and Scalability: The process requires multiple time-consuming steps and is difficult to scale up for industrial production. The cumbersome nature of the protocol leads to significant vesicle loss during preparation, resulting in poor recovery rates [16] [17]. It is not suitable for processing large volumes of bio-fluids efficiently [4].

- Extended Processing Time: A typical UC protocol involves prolonged run times of approximately 70–120 minutes per cycle, often requiring repeats for higher purity. This dramatically reduces throughput [17] [18].

- Compromised Exosome Functionality: The high gravitational forces (100,000–110,000×g) can damage exosomes, affecting their integrity, biological activity, and ultimate therapeutic utility [18].

- Operator Dependency and Reproducibility: The method requires highly skilled technicians to avoid vesicle loss and ensure consistency. Small variations in technique can lead to poor reproducibility, which is a major barrier to clinical standardization [16] [18].

Q2: Are there quantitative data comparing ultracentrifugation with other methods?

Yes, studies directly compare ultracentrifugation with other common techniques. The table below summarizes key findings from a 2024 study that isolated exosomes from H9c2 cells:

Table 1: Comparative Analysis of Exosome Isolation Methods [17]

| Isolation Method | Mean Particle Size (nm) | Impact on Cell Viability (Hypoxic Cells) | Key Characteristics |

|---|---|---|---|

| Ultracentrifugation | 60 | Increased viability by 22% | Smaller size, narrow size distribution, highest functional efficacy |

| Precipitation | 89 | Increased viability by 15% | Moderate yield and function |

| Ultrafiltration | 122 | Increased viability by 11% | Higher variability in vesicle shape and size |

This data shows that while UC can produce homogenous and highly functional exosomes, its scalability and yield limitations remain a primary concern for large-scale production [17].

Q3: What scalable alternatives to ultracentrifugation are emerging?

Recent technological advances offer promising, more scalable paths forward:

- Tangential Flow Filtration (TFF): This method is highly efficient for concentrating extracellular vesicles from large volumes of fluid and is easily scalable [18].

- Size-Exclusion Chromatography (SEC): SEC provides highly purified and homogenous exosomes, though the equipment can be expensive. It is noted for improving yield and purity compared to UC [17] [18].

- Integrated Microfluidic Systems: These platforms, including microfluidic microarrays and deterministic lateral displacement (DLD) chips, enable automated, high-purity isolation with minimal sample loss. They represent the cutting edge in scalable isolation technology and are dominating the revenue share in the exosomes market [4] [19].

- Affinity-Based Methods (Non-Antibody): Kits like the MagCapture Exosome Isolation Kit PS use phosphatidylserine (PS) binding instead of antibodies. This allows for gentler elution under neutral conditions, recovering more intact exosomes with higher purity and efficiency than polymer precipitation or antibody-based methods [20].

Q4: How do isolation methods impact downstream functional analysis and cost?

The choice of isolation method directly affects both the experimental results and the overall cost structure:

- Functional Impact: As shown in Table 1, the isolation method influences the size, homogeneity, and biological functionality of the isolated exosomes. Methods that damage exosomes can lead to misleading conclusions in functional studies [17].

- Cost Impact: Ultracentrifugation, while having low per-run consumable costs, has high overall production costs due to its low throughput, high labor intensity, and requirement for expensive equipment [19]. Scalable methods like TFF and microfluidics offer lower costs per dose at manufacturing scale by automating processes, increasing throughput, and improving yields, which is critical for reducing the cost of clinical-grade exosome manufacturing [4] [19].

Troubleshooting Guide: Overcoming Scalability Challenges

Problem: Low Yield and Poor Recovery from Large Volume Samples

- Potential Cause: Traditional ultracentrifugation is not designed for efficient processing of large volumes. Vesicles are lost on container walls and during multiple transfer steps [20].

- Solution:

- Switch to a scalable concentration technology like Tangential Flow Filtration (TFF). TFF circulates the sample across a membrane, reducing clogging and enabling gentle concentration of large volumes (e.g., 50 mL of cell culture supernatant) down to a workable volume (e.g., 1 mL) [20] [18].

- Follow concentration with a high-resolution purification step such as Size-Exclusion Chromatography (SEC) or affinity-based capture to achieve high purity [17] [18].

- Experimental Protocol (TFF + SEC):

- Pre-clearing: Centrifuge the large-volume cell culture supernatant or biofluid at 300 × g for 10 min to remove dead cells [17].

- Concentration: Use a TFF system with a membrane with a 100kDa molecular weight cut-off (MWCO) to concentrate the sample to a volume of 1-2 mL.

- Purification: Load the concentrated sample onto an SEC column (e.g., qEV columns) to separate exosomes from contaminating proteins based on hydrodynamic volume.

- Characterization: Analyze the final fraction using nanoparticle tracking analysis (NanoSight) for concentration and Western blot for markers (CD9, CD81, CD63) [20].

Problem: Low Purity and Co-isolation of Contaminants

- Potential Cause: Ultracentrifugation often co-pellets protein aggregates, lipoproteins, and other non-exosomal vesicles, leading to contaminated preparations [18].

- Solution:

- Implement a multi-modal approach. Combine methods based on different principles (e.g., size and affinity).

- For complex samples like serum or plasma, introduce a pre-clearing step using size-exclusion chromatography before a specific capture method [16].

- Use affinity purification with magnetic beads targeting specific surface markers (CD9, CD63, CD81) or universal lipids like phosphatidylserine (PS) for higher specificity [16] [20].

- Experimental Protocol (PS Affinity Capture from Plasma):

- Pre-clearing: Perform size-exclusion chromatography on plasma to remove the majority of contaminating proteins [16].

- Capture: Incubate the pre-cleared fraction with magnetic beads coated with a PS-binding protein (e.g., Tim4) for 1-3 hours.

- Washing: Thoroughly wash the beads with an appropriate buffer to remove non-specifically bound material.

- Elution: Elute the intact exosomes by adding a chelating agent (like EDTA) in a neutral pH buffer, which disrupts the PS-Tim4 interaction without damaging the exosomes. This yields a purer preparation than acidic elution [20].

Problem: Inconsistent Results and Poor Reproducibility

- Potential Cause: Ultracentrifugation is highly sensitive to operator technique, rotor type, and subtle variations in centrifugation speed, time, and braking conditions [18].

- Solution:

- Transition to automated and standardized platforms.

- Integrated microfluidic devices offer a "lab-on-a-chip" solution that minimizes manual handling, standardizes the isolation process, and improves reproducibility [4] [19].

- Adopt harmonized protocols and use kit-based systems where the reagents and steps are rigorously controlled [4] [20].

- Workflow Comparison: The following diagram contrasts the workflows of traditional ultracentrifugation and an integrated microfluidic approach, highlighting the complexity and scalability bottlenecks.

The Scientist's Toolkit: Research Reagent Solutions for Scalable Isolation

Table 2: Key Reagents and Kits for Advanced Exosome Isolation

| Research Reagent / Kit | Principle of Isolation | Key Function / Advantage | Scalability Potential |

|---|---|---|---|

| MagCapture Exosome Isolation Kit PS [20] | Phosphatidylserine (PS) Affinity | Binds PS on exosome surface via Tim4 protein; gentle, non-antibody, neutral pH elution preserves functionality. | High (Beads are reusable; compatible with large volumes post-concentration) |

| Dynabeads (CD9/CD63/CD81) [16] | Immunoaffinity Capture | Uses antibody-coated magnetic beads for highly specific exosome subpopulation isolation. | Moderate (Ideal for specific capture; cost may be prohibitive for very large scale) |

| Size-Exclusion Chromatography (SEC) Columns (e.g., qEV) [17] [18] | Size-Based Separation | Separates particles by hydrodynamic volume; excellent for obtaining high-purity, functional exosomes. | High (Columns available for different throughputs; easily scalable) |

| Tangential Flow Filtration (TFF) Cassettes [18] | Size-Based Filtration | Gentle concentration and diafiltration of large sample volumes; high recovery and scalability. | Very High (Industry standard for bioprocessing and volume reduction) |

| Microfluidic Chips (e.g., EXODUS, DLD) [4] [19] | Microfluidics / Affinity / Size | Automated, portable systems for high-purity isolation with minimal sample loss and high throughput. | Growing (Rapidly advancing for clinical and diagnostic applications) |

Regulatory and Standardization Challenges in Clinical-Grade Production

Frequently Asked Questions (FAQs) on Regulations and Manufacturing

Q: How are exosome-based therapeutics classified by major regulatory bodies?

A: Classification depends on the degree of manipulation and intended use, which dictates the regulatory pathway. The following table summarizes the approach from key regulators [21] [22].

| Regulatory Body | Classification & Regulatory Pathway | Key Determining Factors |

|---|---|---|

| U.S. FDA [22] | Drug/Biological Product (Section 351) [22]: Requires IND (Investigational New Drug) and BLA (Biologics License Application).Minimally Manipulated HCT/P (Section 361) [22]: Less stringent pathway, no pre-market approval. |

Section 351: Engineered cargo, non-homologous use, or more than minimal manipulation [22].Section 361: Minimal manipulation, homologous use, no systemic effect [22]. |

| EU EMA [22] | Advanced Therapy Medicinal Product (ATMP) [22]: Requires centralized marketing authorization.Directive 2001/83/EC [22]: For non-ATMP products. |

ATMP: Substantial manipulation (e.g., genetic modification, loaded with therapeutics) or non-homologous use [22]. |

| Singapore HSA | Cell, Tissue, or Gene Therapy Product (CTGTP) [22] | Substantial manipulation, non-homologous function, engineered cargo, or allogeneic use [22]. |

| Thailand TFDA | Biological Medicinal Product [22] | Regulated under the Drug Act, analogous to cell and gene therapies [22]. |

Q: What are the primary challenges in scaling up exosome production for clinical use?

A: Scalability is hindered by issues across the entire manufacturing pipeline [3] [23] [24].

- Upstream Challenges:

- Cell Source Limitations: Many cells used (e.g., Mesenchymal Stem Cells) are anchorage-dependent and difficult to culture at large scale [23].

- Bioreactor Systems: Transitioning from flasks to scalable bioreactors (e.g., hollow-fiber, microcarrier-based) requires precise control to maintain cell phenotype and exosome quality [3] [23].

- Productivity: Increasing the exosome secretion rate from cells remains a significant hurdle [3] [23].

- Downstream Challenges:

- Purification and Purity: Isolating high-purity exosomes from culture media at a large scale is complex. Legacy methods like ultracentrifugation (UC) are poorly scalable and can lead to low yield and impurity co-isolation [3]. A critical concern is the co-purification of viruses or protein aggregates with similar physical characteristics [23] [22].

- Storage and Stability: Exosomes are often stored at -80°C, which is impractical for a commercial pharmaceutical product. Data on shelf-life and in vivo stability is limited [24].

Q: What downstream purification methods are scalable for clinical-grade exosomes?

A: Moving beyond ultracentrifugation is key to scalability. The following methods offer more robust and scalable alternatives [3].

| Method | Principle | Scalability & Advantages | Considerations |

|---|---|---|---|

| Tangential Flow Filtration (TFF) [3] | Size-based separation using tangential flow to minimize membrane clogging. | Highly scalable; higher recovery yield and better impurity removal than UC; improved batch-to-batch consistency [3]. | May not fully remove all impurities on its own [3]. |

| Chromatography (e.g., Anion Exchange - AIEX) [3] | Binds exosomes based on negative surface charge. | Highly scalable; high purity; effective removal of process impurities like surfactants; fast processing (e.g., <3 hours) [3]. | Requires optimization of binding and elution conditions [3]. |

| Bind-Elute Size Exclusion Chromatography (BE-SEC) [3] | Separates by size with a binding step to the matrix. | Improved scalability over traditional SEC; allows for loading larger sample volumes [3]. | Often used in combination with other methods like TFF for optimal results [3]. |

| Super Absorbent Polymer (SAP) Beads [3] | Absorb small molecules like water, thereby concentrating EVs. | Rapid, single-step enrichment of EVs with high purity from various fluids [3]. | Emerging technology. |

Q: What are the critical quality control assays required for exosome characterization?

A: Robust quality control is essential for regulatory approval and requires a multi-parameter approach [25] [22] [15].

| Attribute | Key Assays & Methods | Purpose & Standards |

|---|---|---|

| Identity | Nanoparticle Tracking Analysis (NTA), Tunable Resistive Pulse Sensing (TRPS) [25], Dynamic Light Scattering (DLS) [15]. | Determine particle size distribution (30-150 nm) and concentration [25] [15]. |

| Purity | Transmission Electron Microscopy (TEM) [25] [15], Protein assays (e.g., BCA). | Assess morphology and confirm the absence of cellular debris or co-isolated impurities. Purity is often expressed as a ratio of particle count to protein amount [22]. |

| Characterization | Western Blot [25] [15], Flow Cytometry [25] [15]. | Detect presence of positive (e.g., CD63, CD81, CD9, TSG101, Alix) and negative marker proteins [25]. |

| Potency | Cell-based uptake or functional assays [22]. | Measure the biological activity relevant to the intended therapeutic function. This is lot-specific and linked to the mechanism of action [22]. |

| Safety | Endotoxin (LAL) testing, sterility testing, and assays for adventitious agents [22]. | Ensure the product is free from microbial and viral contaminants [22]. |

GMP Workflow for Exosome Manufacturing

Troubleshooting Guides for Common Experimental Issues

Problem: Low Yield During Exosome Isolation

Potential Causes and Solutions:

- Cause 1: Inefficient isolation protocol.

- Solution: Transition from ultracentrifugation (UC) to more efficient methods like Tangential Flow Filtration (TFF). One study showed TFF concentration efficiency was 100 times higher than UC (10^10 EVs/10^6 cells for TFF vs 10^8 EVs/10^6 cells for UC) [3].

- Solution: Implement a combination of TFF and Bind-Elute Size-Exclusion Chromatography (BE-SEC) for improved yield and purity [3].

- Cause 2: Low exosome secretion from source cells.

- Cause 3: Starting material is insufficient or degraded.

- Solution: Ensure cells are healthy and the conditioned media is fresh and processed promptly [15]. Increase the volume of starting material if necessary.

Problem: Poor Purity (Contamination with Proteins, Other Vesicles)

Potential Causes and Solutions:

- Cause 1: Single-step purification is insufficient.

- Solution: Employ a multi-step purification strategy. For example, use TFF for concentration and initial volume reduction, followed by Anion Exchange Chromatography (AIEX) for high-purity purification. AIEX effectively removes contaminants like bovine serum albumin and non-ionic surfactants [3].

- Cause 2: Co-isolation of non-exosome particles.

- Solution: Use immunoaffinity capture with antibodies against specific exosome surface markers (e.g., CD63, CD81) for high specificity, though this can be costly and less scalable [15].

- Solution: Implement density gradient centrifugation as an additional polishing step to separate exosomes from proteins and other contaminants [25].

Problem: Inconsistent Results Between Batches

Potential Causes and Solutions:

- Cause 1: Uncontrolled cell culture conditions.

- Solution: Implement strict process controls for upstream culture (pH, dissolved oxygen, temperature, and media components) to ensure parental cells remain phenotypically stable [3] [23].

- Solution: Use bioreactor systems that offer better environmental control and scalability compared to flask-based cultures [3].

- Cause 2: Lack of standardized protocols and quality controls.

- Solution: Establish a robust Quality-by-Design (QbD) approach. Define Critical Quality Attributes (CQAs) and Critical Process Parameters (CPPs) for your manufacturing process [22].

- Solution: Use qualified and validated assays for in-process testing and final product release to ensure batch-to-batch consistency [22].

Troubleshooting Inconsistent Batches

Problem: Exosomes Lack Expected Biological Activity in Functional Assays

Potential Causes and Solutions:

- Cause 1: Damage during isolation or storage.

- Solution: Avoid repeated freeze-thaw cycles, which can damage exosome integrity and cause content leakage [15]. Store exosomes in single-use aliquots at -80°C and use cryoprotectants like trehalose [15].

- Solution: Choose gentle isolation methods. Harsh techniques like prolonged ultracentrifugation can cause exosome aggregation or loss of function [3].

- Cause 2: Incorrect or degraded markers in characterization.

- Solution: In Western Blot analysis, if expected markers (e.g., CD63, CD81) are not detected, verify antibody specificity and storage conditions. It is advised to test antibodies from multiple manufacturers [15].

- Solution: Use a combination of characterization techniques (NTA, TEM, Western Blot) to confirm you have isolated intact exosomes [25] [15].

The Scientist's Toolkit: Essential Research Reagent Solutions

This table details key materials and their functions for establishing a robust exosome manufacturing and quality control platform [3] [23] [25].

| Reagent / Material | Function & Application | Cost & Standardization Benefit |

|---|---|---|

| Chemically Defined, Xeno-Free Media | Eliminates variability and adventitious agents from serum (e.g., FBS), ensuring consistent cell growth and exosome production [22]. | Reduces contamination risk; simplifies downstream purification; improves regulatory compliance [22]. |

| Master Cell Bank | A standardized, well-characterized stock of parental cells ensures a consistent and renewable source for production, minimizing genetic drift [25] [22]. | Foundation of batch-to-batch consistency; critical for regulatory filings (IND/BLA) [22]. |

| Tangential Flow Filtration (TFF) Cassettes | For scalable concentration and buffer exchange of exosomes from large volumes of conditioned media [3]. | Higher recovery yield and scalability than UC; reduces processing time and costs [3]. |

| Chromatography Resins (e.g., AIEX) | For high-purity purification of exosomes, removing proteins, surfactants, and other impurities based on surface charge [3]. | Delivers clinical-grade purity; scalable and reproducible; replaces multiple legacy steps [3]. |

| CD63, CD81, CD9 Antibodies | Key reagents for identity testing via Western Blot or Flow Cytometry to confirm the presence of exosomes [25] [15]. | Essential for quality control and release criteria; confirms product identity. |

| Nanoparticle Tracking Analysis (NTA) | Provides quantitative data on particle size distribution and concentration [25] [15]. | Critical release assay; ensures product meets specifications for identity and purity. |

| Cryoprotectants (e.g., Trehalose) | Protects exosome integrity during freezing and long-term storage at -80°C, preventing aggregation and loss of function [15]. | Preserves product stability and potency, extending shelf-life and reducing waste. |

Next-Generation Production Workflows: Advanced Methods for Scalable Exosome Isolation and Purification

For researchers and drug development professionals focused on large-scale clinical grade exosome manufacturing, moving beyond traditional ultracentrifugation (UC) is a critical step toward viable commercialization. Ultracentrifugation presents significant limitations in yield, scalability, and cost-efficiency, making it poorly suited for industrial-scale production. This technical support center provides practical guidance on implementing Tangential Flow Filtration (TFF) combined with Size-Exclusion Chromatography (SEC) - a superior isolation workflow that addresses these limitations while maintaining high exosome quality and functionality for therapeutic applications.

Frequently Asked Questions (FAQs) & Troubleshooting

Q1: What are the concrete advantages of TFF-SEC over ultracentrifugation for large-scale exosome production?

A1: Direct comparative studies demonstrate that TFF-SEC outperforms UC-based methods across several key parameters, especially for processing large volumes like cell culture media [26] [27].

Table: Direct Comparison of TFF-SEC vs. UC-SEC Performance

| Performance Parameter | TFF-SEC | UC-SEC |

|---|---|---|

| Particle Yield | Up to 23-fold higher [27] | Low, significant particle loss |

| Process Time | Significantly faster [27] | Time-consuming, multiple steps [27] |

| Cost per Isolation | < One-tenth the cost of UC [27] | High (equipment, tubes, labor) |

| Scalability | Highly scalable for large volumes [26] [28] | Limited by rotor capacity |

| EV Integrity & Function | Gentle process; preserves integrity [27] | High g-forces can damage EVs and cause aggregation [26] |

| Reproducibility | High and consistent [26] [28] | Lower due to manual, multi-step process [26] |

Q2: We are experiencing a rapid pressure increase during the TFF process. What could be the cause?

A2: A sudden pressure spike typically indicates membrane fouling or blockage. To troubleshoot [28]:

- Check Feed Stream: Clarify your cell culture media thoroughly before TFF. Use sequential centrifugation (e.g., 500 × g for 10 min to remove cells, then 0.22 μm filtration) to remove debris and large particles that can clog the membrane [26].

- Optimize TMP and CFF: An excessively high Transmembrane Pressure (TMP) can compress the fouling layer on the membrane. Try reducing the TMP and increasing the Cross-Flow Flux (CFF) to enhance the sweeping effect across the membrane surface [28].

- Implement a Cleaning-in-Place Protocol: For reusable TFF systems, establish a rigorous cleaning regimen using appropriate buffers (e.g., NaOH) immediately after processing to prevent residual protein or lipid adhesion [28].

Q3: Our final exosome preparation from TFF-SEC has high protein contamination. How can we improve purity?

A3: High protein content suggests insufficient separation during the SEC step. Consider these adjustments:

- Verify Column Loading Capacity: Do not overload the SEC column. The sample volume loaded should typically not exceed 10% of the total column volume. Concentrate your TFF-retentate to an optimal volume before SEC [27].

- Fraction Collection Strategy: Ensure you are accurately collecting the exosome-rich fractions (typically the void volume) and discarding the later protein-rich fractions. Using an automatic fraction collector can improve precision and reproducibility [27].

- Buffer Compatibility: Ensure the buffer used for diafiltration during TFF is compatible with your SEC mobile phase to avoid buffer exchange issues that can impact resolution [28].

Q4: How can we monitor and maintain consistent performance of our SEC columns over time?

A4: Consistent column performance is key to reproducible exosome isolation.

- Pressure Monitoring: Know the typical back-pressure for your new SEC column setup. A sustained increase in pressure indicates potential blockage, often in the column frits or pre-column filter [29].

- Performance Tests: Regularly test column performance by running a well-characterized control sample or a standard (e.g., monodisperse proteins or beads). Calculate the plate count and asymmetry factor periodically. A decrease in plate count or a shift in asymmetry (tailing or fronting) indicates a deteriorated column that needs cleaning or replacement [29].

- Proper Storage: Always store SEC columns in the recommended preservative solution (often containing an antimicrobial like sodium azide) as per the manufacturer's instructions to prevent microbial growth and column degradation [29].

Detailed Experimental Protocol: TFF-SEC Workflow for Exosome Isolation

This protocol is optimized for processing large volumes of cell culture conditioned media, based on the method validated by Visan et al. (2022) [26].

Step 1: Cell Culture and Media Clarification

- Cell Culture: Culture your chosen cell line (e.g., HeLa, MDA-MB-231) in media supplemented with 5% EV-depleted FBS (prepared by ultracentrifugation at 100,000 × g overnight) to reduce serum-derived EV background [26].

- Collection: Collect conditioned media after 48 hours.

- Clarification:

- Centrifuge at 500 × g for 10 minutes to remove detached cells.

- Filter the supernatant through a 0.22 μm PES membrane filter to remove larger particles and debris [26].

Step 2: Pre-concentration and Initial Purification via Tangential Flow Filtration (TFF)

- System Setup: Use a TFF system equipped with a cartridge or hollow fiber module with a molecular weight cutoff (MWCO) of 100-500 kDa [28].

- Concentration: Recirculate the clarified media through the TFF system until the volume is reduced 50-100 fold. The exosomes are retained in the retentate.

- Diafiltration (Buffer Exchange): Continue the process by adding Diafiltration Buffer (e.g., PBS, pH 7.4) to the retentate reservoir at the same rate as permeate generation. Perform a 5-10 volume diafiltration to effectively exchange the buffer and remove small contaminants [28].

- Final Retentate Recovery: Recover the final, concentrated retentate (now in a suitable SEC-compatible buffer). This is your pre-purified exosome sample.

Step 3: Final Purification via Size-Exclusion Chromatography (SEC)

- Column Preparation: Equilibrate your chosen qEV or equivalent SEC column with at least 2-3 column volumes of filtered PBS or your chosen mobile phase [27].

- Sample Loading: Load the concentrated TFF retentate onto the column, ensuring the load volume does not exceed 10% of the total column volume.

- Fraction Collection: Elute with mobile phase and collect sequential fractions.

- Fractions 1-3 (Void Volume): Typically contain the purified, intact exosomes [27].

- Later Fractions: Contain soluble proteins and other small contaminants. Discard or collect separately.

- Characterization: Pool the exosome-rich fractions and characterize by Nanoparticle Tracking Analysis (NTA), protein quantification (e.g., BCA assay), and western blot for classic exosome markers (CD9, CD63, CD81, TSG101).

Workflow Visualization

The Scientist's Toolkit: Key Research Reagent Solutions

Table: Essential Materials and Equipment for TFF-SEC Exosome Isolation

| Item | Function/Description | Example/Considerations |

|---|---|---|

| TFF System | For gentle concentration and buffer exchange of large-volume samples. | KrosFlo systems; Hollow Fiber Modules for shear-sensitive samples; Flat Sheet Cassettes for higher flux [28]. |

| SEC Columns | High-resolution separation of exosomes from contaminating proteins based on hydrodynamic volume. | qEV columns; Pre-packed columns ensure reproducibility and ease of use [27]. |

| EV-Depleted FBS | Fetal Bovine Serum processed to remove bovine exosomes for cell culture. | Essential for reducing background contamination in cell culture media; prepared via ultracentrifugation (100,000 × g, overnight) or commercial sources [26]. |

| Diafiltration Buffer | A compatible buffer (e.g., PBS, saline) for TFF to exchange media and remove contaminants. | Must be sterile-filtered and compatible with downstream SEC and cell-based assays [28]. |

| Characterization Tools | For quantifying and qualifying the final exosome product. | NTA (particle concentration/size), BCA assay (protein contamination), Western Blot (markers: CD9, CD63, TSG101), TEM (morphology) [26] [30]. |

FAQs: Microfluidics and Affinity-Based Capture for Exosome Manufacturing

Q1: How can microfluidic affinity purification specifically reduce costs in large-scale exosome production?

Microfluidic affinity purification reduces costs through multiple mechanisms. It significantly minimizes reagent consumption by using micro-scale flow cells and channels, which reduces the required volume of often expensive affinity ligands (e.g., antibodies, aptamers) [31] [32]. Furthermore, these systems achieve high purity and capture efficiency (often above 90% for target cells) in a single, automated process, which reduces the need for repetitive processing steps and associated labor and time costs [31]. The ability to regenerate and reuse the affinity-functionalized surfaces within the microdevice, as demonstrated with aptamer-coated chambers, further enhances cost-effectiveness over multiple production runs [32].

Q2: What are the key advantages of using aptamers over antibodies as affinity ligands in microfluidic devices?

Aptamers, which are synthetic oligonucleotides or peptides, offer several cost and operational advantages. They are produced via synthetic processes (SELEX), making them generally more stable and less expensive to manufacture and modify than antibodies, which are biologically derived [32]. A critical advantage for process control and gentle elution is the ability to reversibly disrupt the aptamer-target binding using a moderate temperature change. This allows for non-destructive release of captured exosomes or cells, maintaining their viability and functionality, which is often challenging with near-irreversible antibody-antigen bonds [32].

Q3: Our team is experiencing low capture efficiency in our microfluidic affinity device. What are the primary factors we should investigate?

Low capture efficiency can be attributed to several factors related to binding kinetics and device operation. First, investigate the binding conditions, including the pH and ionic strength of your binding buffer; physiological conditions such as phosphate-buffered saline (PBS) are commonly used [33]. Second, ensure you are allowing sufficient time for the sample to bind to the immobilized ligands. You can try applying the sample in aliquots and stopping the flow for a few minutes between each application to increase contact time [34]. Finally, verify the expression level of the target biomarker on your exosomes or source cells, as the cell attachment rate has been directly correlated with biomarker expression levels [31].

Q4: We are successfully capturing our targets but struggling with low yield after elution. What elution strategies can we employ?

Elution efficiency depends on breaking the affinity interaction without damaging the target. You can explore several buffer conditions to dissociate the binding partners. Common strategies include using extremes of pH (e.g., 100 mM glycine•HCl, pH 2.5-3.0 or 100 mM triethanolamine, pH 11.5), altering ionic strength (e.g., 3.5–4.0 M MgCl₂), or using chaotropic agents (e.g., 2–6 M guanidine•HCl) [33]. For a gentler, non-denaturing elution, consider a specific competitive ligand that displaces the target [33]. Furthermore, you can try stopping the flow intermittently during elution to allow time for the target to dissociate, collecting the eluate in pulses [34].

Q5: How can we achieve multiplexed affinity-based separation to isolate multiple exosome subpopulations simultaneously?

Multiplexed affinity separation can be achieved using a size-coded bead strategy in an inertial microfluidic device. In this approach, different affinity ligands (e.g., antibodies for different exosome surface markers) are immobilized on microbeads of distinct, predefined sizes [35]. The sample is incubated with this mixed bead population in a single binding step. The mixture is then flowed through a spiral microchannel, where inertial forces focus the bead-target complexes into different streams based on their size, effectively sorting them into different outlets [35]. This method allows for the simultaneous isolation of multiple targets from a single sample, significantly saving time and sample material compared to serial separations.

Troubleshooting Guides

Troubleshooting Affinity Capture and Elution

This table addresses common problems encountered during the affinity capture process.

| Observation | Potential Cause | Recommended Solution |

|---|---|---|

| Low Capture Efficiency | Incufficient binding time or flow rate; suboptimal binding buffer [34] [33]. | Stop flow during sample application to increase incubation time; ensure binding buffer is at physiologic pH (e.g., PBS) [34] [33]. |

| Target Elutes in Broad, Low Peak | Slow dissociation kinetics; weak or non-specific elution conditions [34]. | Try different, stronger elution buffers (e.g., pH shift, chaotropic agents); use stop-flow elution to collect target in pulses [34] [33]. |

| Non-Specific Binding is High | Nonspecific interactions between sample components and the solid support or ligand [33]. | Add low concentrations of detergent (e.g., Tween 20) or moderate salt to wash buffers; ensure proper blocking of the affinity surface [33]. |

| Low Cell Viability Post-Release | Overly harsh elution conditions (e.g., extreme pH, denaturing agents) [32]. | Switch to milder elution methods such as temperature-mediated release (for aptamers) or specific competitive elution [32] [33]. |

Troubleshooting Microfluidic Device Operation

This table addresses issues related to the physical operation of microfluidic systems.

| Observation | Potential Cause | Recommended Solution |

|---|---|---|

| Device Clogging | Presence of large aggregates in sample; debris from cell lysates [31]. | Always pre-filter samples using an appropriate mesh or filter (e.g., 40-100µm) before loading into the microfluidic device [31]. |

| Irregular or Slow Flow | Air bubbles trapped in the microchannels; particulates clogging channels [36]. | Prime all channels thoroughly with buffer; design and use bubble traps; implement inline filters for samples [36]. |

| Poor Reproducibility Between Runs | Inconsistent surface functionalization; carryover from previous runs; variations in flow control [37]. | Establish standardized protocols for surface regeneration [32]; implement stringent cleaning between runs; use precision pumps for consistent flow rates. |

Quantitative Data for Process Planning

Performance Metrics of Affinity-Based Microfluidic Systems

The following table summarizes key performance data from various affinity-based microfluidic strategies, providing benchmarks for process development.

| Application / Technique | Capture Efficiency / Purity | Throughput / Processing Time | Key Quantitative Result |

|---|---|---|---|

| Ephesia CTC Capture (Microfluidic, Antibody-based) | >90% capture efficiency; 70% capture from 10ml blood [31]. | >3 ml/h; Processes 10ml blood in <4 hours [31]. | Captured CTCs in 75% of prostate cancer and 80% of breast cancer patients [31]. |

| Aptamer-Based Cell Capture & Temp-Release | Specific capture of target cells (CCRF-CEM) [32]. | N/D | Released cells remained viable; aptamer surface was regenerable [32]. |

| Multiplexed Inertial Microfluidics (Bead-based) | Separation efficiency of 80% to 95% for different bead sizes [35]. | Processes milligram-scale protein samples or millions of cells in minutes post-binding [35]. | Isolated 1–5 µg of antigen-specific antibody from 1 mg of total serum IgG [35]. |

Common Elution Buffer Systems for Affinity Purification

Choosing the right elution buffer is critical for balancing yield, purity, and target viability.

| Elution Condition | Example Buffer Composition [33] | Typical Use Case & Notes |

|---|---|---|

| Low pH | 100 mM glycine•HCl, pH 2.5-3.0 | Most widely used for antibody-antigen; collect into neutralization buffer (e.g., Tris pH 8.5) [33]. |

| High pH | 50–100 mM triethylamine, pH 11.5 | Alternative to low pH; also requires immediate neutralization of collected fractions [33]. |

| High Ionic Strength | 3.5–4.0 M magnesium chloride, pH 7.0 | Disrupts ionic and hydrophobic interactions; can be harsh for some proteins/cells [33]. |

| Chaotropic | 2–6 M guanidine•HCl | Denatures interactions; can compromise target activity but effective for stubborn binding [33]. |

| Competitive | >0.1 M counter ligand (e.g., glutathione for GST-tags) | Gentle and specific; ideal for preserving target activity and regenerating the affinity surface [33]. |

Experimental Protocols

Protocol: Inertial Microfluidics for Multiplexed Affinity Separation

This protocol describes the simultaneous isolation of multiple targets using size-coded affinity beads and a spiral microfluidic sorter [35].

Key Research Reagent Solutions:

- Size-Coded Microbeads: A mixture of magnetic or non-magnetic polystyrene microbeads of distinct diameters (e.g., 1 µm, 4.5 µm, 6 µm, 10 µm). Beads are pre-coated with streptavidin to enable biotinylation of different capture antigens [35].

- Capture Agents: Different biotinylated "bait" molecules (e.g., antigens for antibody capture, antibodies for exosome subtyping). These are coupled to the respective sized beads via biotin-streptavidin linkage [35].

- Sorting Buffer: A biocompatible buffer (e.g., PBS with 0.1% BSA) to maintain target stability during the inertial sorting process.

Methodology:

- Bead Preparation: Incubate each biotinylated capture antigen with a specific size of streptavidin-coated microbeads. Optimize the beads-to-protein mass ratio for maximum coverage. Wash the beads to remove unbound antigen [35].

- Sample Binding: Combine the prepared mixture of size-coded affinity beads with the clinical or research sample (e.g., serum, cell culture supernatant). Incubate with gentle mixing to allow targets to bind to their respective beads [35].

- Binding Verification (Optional): Pellet the beads and measure the target concentration in the supernatant (e.g., via ELISA) to verify capture efficiency [35].

- Microfluidic Sorting: Resuspend the bead mixture in sorting buffer and introduce it into the spiral inertial microfluidic device. Use a sheath flow to focus the particles. The device will sort the bead-target complexes into different outlets based on their size [35].

- Target Elution and Collection: Collect the output streams from each outlet. Elute the purified targets from the beads using an appropriate elution buffer (e.g., low-pH glycine buffer, optimized for ~5 minutes). Immediately neutralize the eluate if necessary [35].

- Downstream Analysis: The isolated, purified targets are now ready for downstream applications such as functional assays, molecular analysis, or quantification.

Protocol: Temperature-Mediated Cell Capture and Release Using Aptamers

This protocol outlines a method for the specific capture and gentle release of cells or exosome-producing cells using an aptamer-functionalized microfluidic device with integrated temperature control [32].

Key Research Reagent Solutions:

- Cell-Specific Aptamers: DNA or RNA aptamers (e.g., sgc8c for CCRF-CEM cells) selected for the target cell type. These are synthesized with chemical modifications for surface immobilization [32].

- Microfluidic Device: A PDMS or glass device featuring a microchamber situated on a chip with integrated heaters and a temperature sensor for precise thermal control [32].

- Binding & Wash Buffer: A physiologically compatible buffer to maintain cell viability and support aptamer-target binding.

Methodology:

- Surface Functionalization: Immobilize the aptamer molecules on the solid surfaces within the microfluidic chamber using standard chemistry (e.g., thiol-gold or biotin-streptavidin) [32].

- Specific Capture: Introduce the cell suspension into the device and incubate for a predetermined time. Target cells are captured by the surface-immobilized aptamers via affinity binding [32].

- Washing: Flush the chamber with wash buffer to remove non-specifically bound and non-target cells [32].

- Temperature-Mediated Release: Increase the temperature of the chamber using the integrated heaters. A moderate temperature change is sufficient to reversibly disrupt the aptamer-cell interaction, releasing the captured cells without harming their viability [32].

- Collection and Analysis: Collect the eluted, viable cells from the outlet for downstream culture or analysis. The aptamer-functionalized surface can be cooled and regenerated for device reuse [32].

Signaling Pathways, Workflows, and Logical Relationships

Comparative Analysis of Extracellular Vesicle Therapeutics

Comparative analysis of key therapeutic vesicles for research and development planning [37].

Microfluidic Affinity-Capture and Release Workflow

Generalized workflow for target purification using microfluidic affinity capture and release [31] [32] [33].

Frequently Asked Questions (FAQs)

Cell Source Selection

Q1: What are the key criteria for selecting a cell source for high-yield exosome production?

The optimal cell source balances high intrinsic EV secretion yield, scalability, and therapeutic relevance. Mesenchymal stem cells (MSCs) are widely used due to their high EV secretion rate and therapeutic potential in regenerative medicine [38]. However, source matters; for instance, adipose-derived MSCs (ADSCs) and umbilical cord-derived MSCs (UCMSCs) are common choices [39]. The donor's age and health status are critical, as cells from older donors may produce exosomes with diminished regenerative capabilities [39]. For large-scale production, immortalized cell lines are often preferred for their infinite expansion capabilities, bypassing the need for constant validation of new primary cell batches [40].

Q2: How does the choice of cell source impact downstream manufacturing costs?

Selecting a consistent and scalable cell source is a primary lever for cost reduction. Primary cells, like MSCs, have a finite expansion capacity, leading to repeated, expensive validation processes [40]. Using well-characterized, immortalized cell lines can significantly reduce these long-term costs and ensure batch-to-batch consistency [40]. Furthermore, some alternative sources, such as red blood cells (RBCs), offer very high yields and can bypass the need for complex large-scale culture systems altogether, presenting a major cost-saving opportunity [41].

Bioreactor and 3D Culture Strategies

Q3: What are the advantages of 3D culture systems over traditional 2D flasks for scale-up?

Shifting from 2D to 3D culture is a key strategy to enhance EV yield and physiological relevance, directly impacting cost-efficiency by producing more vesicles per unit of volume [42]. 3D cultures, including spheroids, hydrogels, and bioreactors, better mimic the in vivo cellular environment.

Table: Comparative Analysis of 2D vs. 3D Culture Systems for EV Production

| Feature | 2D Culture | 3D Culture |

|---|---|---|

| Physiological Relevance | Low; oversimplifies cell environment [42] | High; better mimics tissue conditions [42] |

| EV Yield | Standard | Significantly enhanced; one study showed higher EV secretion from 3D spheroids [42] |

| EV Cargo | Standard | Can be altered; enrichment of specific miRNAs and proteins (e.g., GPC-1) reported [42] |

| Scalability | Limited by surface area | High, especially with bioreactors [43] |

| Cost-Effectiveness | Lower upfront cost | Higher yield and functionality can reduce overall cost per EV unit |

Q4: How do bioreactors contribute to large-scale, clinical-grade production?

Bioreactors are indispensable for automating and scaling up cell culture to meet clinical demands for EVs [44]. They provide a controlled environment for massive cell expansion, which is the foundation of high-volume EV production [45]. These systems support advanced 3D culture using microcarriers or as spheroid suspension cultures, dramatically increasing the cell density compared to multilayer flasks [43]. This leads to a higher volume of conditioned media and a greater total harvest of EVs, making the entire process more scalable and economically viable for clinical applications [38] [44].

Process Optimization and Troubleshooting

Q5: What are common stimulation strategies to boost EV secretion from cells?

Several physicochemical modulation strategies can be employed to stimulate cells and enhance EV production without increasing culture volume, thus improving productivity [43].

Table: Strategies for Enhancing EV Production Yield [43]

| Modulation Type | Examples | Reported Effect on EV Production |

|---|---|---|

| Chemical | Serum starvation, Acidic pH (~6.5), Mild heat stress (40-42°C), Hypoxia | Increases EV release; acidic pH reported to boost yield up to 69-fold in some cancer cells [43] |

| Chemical | Small molecules (e.g., Norepinephrine, Forskolin) | Induces ceramide generation and Rab27 protein expression to promote secretion [43] |

| Mechanical | Shear stress, Ultrasound | Applies physical forces to stimulate cellular response and EV release [43] |

| Structural | 3D Culture Systems (Spheroids, Bioreactors) | Increases EV yield and alters cargo composition [42] [43] |

Q6: How can we monitor and control the production process to ensure consistency and quality?

Implementing Process Analytical Technologies (PAT) and AIoT (Artificial Intelligence of Things) is transformative for ensuring consistency. AIoT enables real-time, 24/7 monitoring of critical parameters like temperature, pH, gas composition, and equipment performance [44]. This automated oversight minimizes human error, provides complete digital audit trails for regulatory compliance, and allows for proactive intervention to maintain product quality across batches [44].

Troubleshooting Guides

Problem 1: Low EV Yield from Cell Culture

Potential Causes and Solutions:

- Cause: Suboptimal Cell Health and Density.

- Cause: Inadequate Culture Conditions.

- Solution: Employ physicochemical stimulation.

- Protocol for Serum Starvation: Culture cells in serum-free medium (e.g., Opti-MEM) for a defined period (e.g., 120 hours). This stress can upregulate EV biogenesis genes (e.g., ARF6, Rab family) [43].

- Protocol for Chemical Induction: Treat cells with chemical inducers like forskolin (e.g., 10 µM for 24 hours) to enhance EV secretion via the ceramide pathway [43].

- Solution: Employ physicochemical stimulation.

- Cause: Using 2D Culture Systems.

- Solution: Transition to 3D culture.

- Protocol for Spheroid Formation: Use ultra-low attachment (ULA) plates. Centrifuge cell suspension in ULA plates and incubate on a rotary shaker to promote 3D spheroid aggregation [42].

- Solution: Transition to 3D culture.

Problem 2: High Batch-to-Batch Variability

Potential Causes and Solutions:

- Cause: Inconsistent Cell Source or Passaging.

- Solution: Use well-characterized, low-passage cell banks. Standardize protocols for cell passaging and avoid using over-passaged or senescent cells, as aging donor cells produce exosomes with reduced functionality [39].

- Cause: Uncontrolled Manual Processes.

- Solution: Implement automated, closed-system technologies and AIoT-based monitoring. This reduces human error and provides real-time tracking of critical process parameters (temperature, pH, gas) to ensure every batch is produced under identical, validated conditions [44].

- Cause: Non-GMP Compliant Facility Design.

- Solution: Adhere to PIC/S GMP guidelines with a Contamination Control Strategy (CCS). This includes using closed isolator systems, H₂O₂ sterilization, Rapid Transfer Ports (RTPs), and separate routes for personnel and materials to minimize cross-contamination [44].

Problem 3: Inefficient Scalability from Research to Clinical Grade

Potential Causes and Solutions:

- Cause: Reliance on Planar 2D Culture.

- Solution: Integrate bioreactors early in development. Bioreactors support automated, large-scale 3D culture and are indispensable for producing the required EV volumes for clinical trials (e.g., doses ranging from 10^6 to 10^11 particles per treatment) [38].

- Cause: Lack of a Robust Downstream Process.

- Solution: Plan for scalable purification (e.g., tangential flow filtration) and aseptic fill-finish processes early on. Implement sterile freeze-drying (lyophilization) to enhance product shelf-life and stability, facilitating storage and transport [44].

The Scientist's Toolkit: Key Research Reagent Solutions

Table: Essential Materials for Optimizing Upstream EV Production

| Research Reagent / Material | Function in Upstream Production |

|---|---|

| Ultra-Low Attachment (ULA) Plates | Promotes scaffold-free 3D spheroid formation by minimizing cell adhesion [42]. |

| Bioreactors | Provides an automated, controlled environment for large-scale 3D cell culture and EV production [44] [43]. |

| Serum-Free Media (e.g., Opti-MEM) | Used in serum-starvation protocols to stimulate EV biogenesis and avoid FBS-derived contaminating vesicles [43]. |

| Chemical Inducers (e.g., Forskolin) | Small molecules that enhance EV secretion by modulating intracellular pathways like ceramide generation [43]. |

| Dynabeads (CD9/CD63/CD81) | Magnetic beads for immunoaffinity capture of exosomes; used for quantification and analysis of specific EV subpopulations [16]. |

| AIoT Monitoring Platform | Provides real-time, automated oversight of critical process parameters (T°, pH, gas) to ensure consistency and compliance [44]. |

| Closed Isolator Systems with H₂O₂ Sterilization | Creates an aseptic Class A environment for cell culture and fill-finish operations, critical for GMP compliance [44]. |

Embracing Allogeneic 'Off-the-Shelf' Models for Standardized, Scalable Production

Technical Support Center: Troubleshooting Large-Scale Allogeneic Exosome Production

Troubleshooting Guide: Common Production Challenges

Issue 1: Low Exosome Yield from Allogeneic Stem Cell Cultures

- Problem: Inadequate exosome quantity for clinical-scale production.

- Solution: Implement optimized upstream production strategies.

- Biochemical Stimulation: Add specific growth factors or cytokines (e.g., IFN-γ, TNF-α, BMP-2, HIF-1α) to the culture medium to enhance cellular activity and vesicle secretion [46].

- Physical Stimulation: Culture cells under mild hypoxia or thermal stress, or use serum starvation to stimulate exosome release [46].

- 3D Culture Systems & Bioreactors: Transition from 2D flasks to 3D culture systems or use instrumental strategies like hollow-fiber bioreactors and stirred tank bioreactors to significantly increase cell density and, consequently, exosome yield [46].

Issue 2: Inconsistent Exosome Product Quality and Potency

- Problem: Batch-to-batch variability in exosome characteristics and function.

- Solution: Standardize the manufacturing process through automation and control.

- Master Cell Banks (MCBs): For allogeneic therapies, start with a well-characterized, clonal master cell bank derived from a single donor to ensure a consistent and uniform starting material [47].

- Process Control: Utilize closed-system automated bioreactors to minimize manual handling, reduce contamination risk, and ensure process consistency across production runs [48] [49].

- Quality Control (QC) Testing: Implement robust, standardized QC assays to monitor critical quality attributes (CQAs) like particle concentration, size distribution, surface marker profile (e.g., CD9, CD63, CD81), and potency for each batch [48] [16].

Issue 3: Inefficient and Low-Purity Exosome Isolation

- Problem: Traditional isolation methods are inefficient, low-yield, or co-purify contaminants.

- Solution: Evaluate and select isolation techniques based on scale and purity requirements.

- Large-Scale Techniques: For initial processing of large volumes of conditioned media, consider techniques like Tangential Flow Filtration (TFF) or Size-Exclusion Chromatography (SEC), which are more amenable to scaling and can provide good purity [46].

- Combined Methods: A common strategy is to use a combination of methods, such as concentrating the medium via ultrafiltration followed by purification using SEC, to achieve both high yield and high purity [46].

Issue 4: Poor Post-Thaw Viability and Functionality

- Problem: Exosomes or producer cells lose functionality after cryopreservation and thawing.

- Solution: Optimize cryopreservation and post-thaw protocols.

- Cryopreservation Media: Use optimized cryoprotectant formulations. For cells, this often includes DMSO. For exosomes, storing in PBS with 0.1% BSA has been reported to maintain stability after freezing at -80°C [16].

- Controlled-Rate Freezing: Use controlled-rate freezers to ensure a consistent and optimal freezing curve, which helps maintain cell viability and exosome integrity.

- Post-Thaw Assessment: Always conduct viability and functional assays post-thaw to ensure the product has retained its critical therapeutic properties before use or release [48].

Frequently Asked Questions (FAQs)